POLARIS Laboratories® Invests in Proprietary AI/ML Software to Provide Predictive Maintenance and Analytics for Its Global Manufacturing Customers

POLARIS Laboratories®

Case Study

Key Stats

Company History

Founded in 1999, POLARIS Laboratories now serves a global manufacturing customer base with laboratory testing, data analytics and maintenance actions to reduce downtime.

Operating out of a 60,000 square-foot production headquarters facility on the Northwest side of Indianapolis, Indiana, POLARIS Laboratories® has grown into one of the largest independent oil analysis laboratories in North America. The company’s name itself is an acronym: Performance Oil Analysis Laboratories and Reliable Information Systems. When POLARIS Laboratories® was initially founded in 1999, the organizers recognized the large abundance of data the laboratory would produce and saw a critical need to have software to convert the data to actionable information for customers. Today, the company’s “one-laboratory, multiple locations” business model provides its industrial customers with cutting-edge technology solutions to support equipment maintenance schedules by delivering scientific laboratory testing and analysis of fluid samples. When customers partner with POLARIS Laboratories®, users can assess and prevent machine and equipment downtime based on regularly scheduled analyses of equipment fluids such as oil, greases, coolants and fuels. POLARIS Laboratories® analytics are developed from more than 15 million historical samples tested over the last 23 years in the laboratory’s seven laboratory facilities across the globe. As an analysis laboratory, POLARIS Laboratories’ product is information – which supports the manufacturing ecosystem, helping customers be more efficient and informed about the state of their machines and equipment.

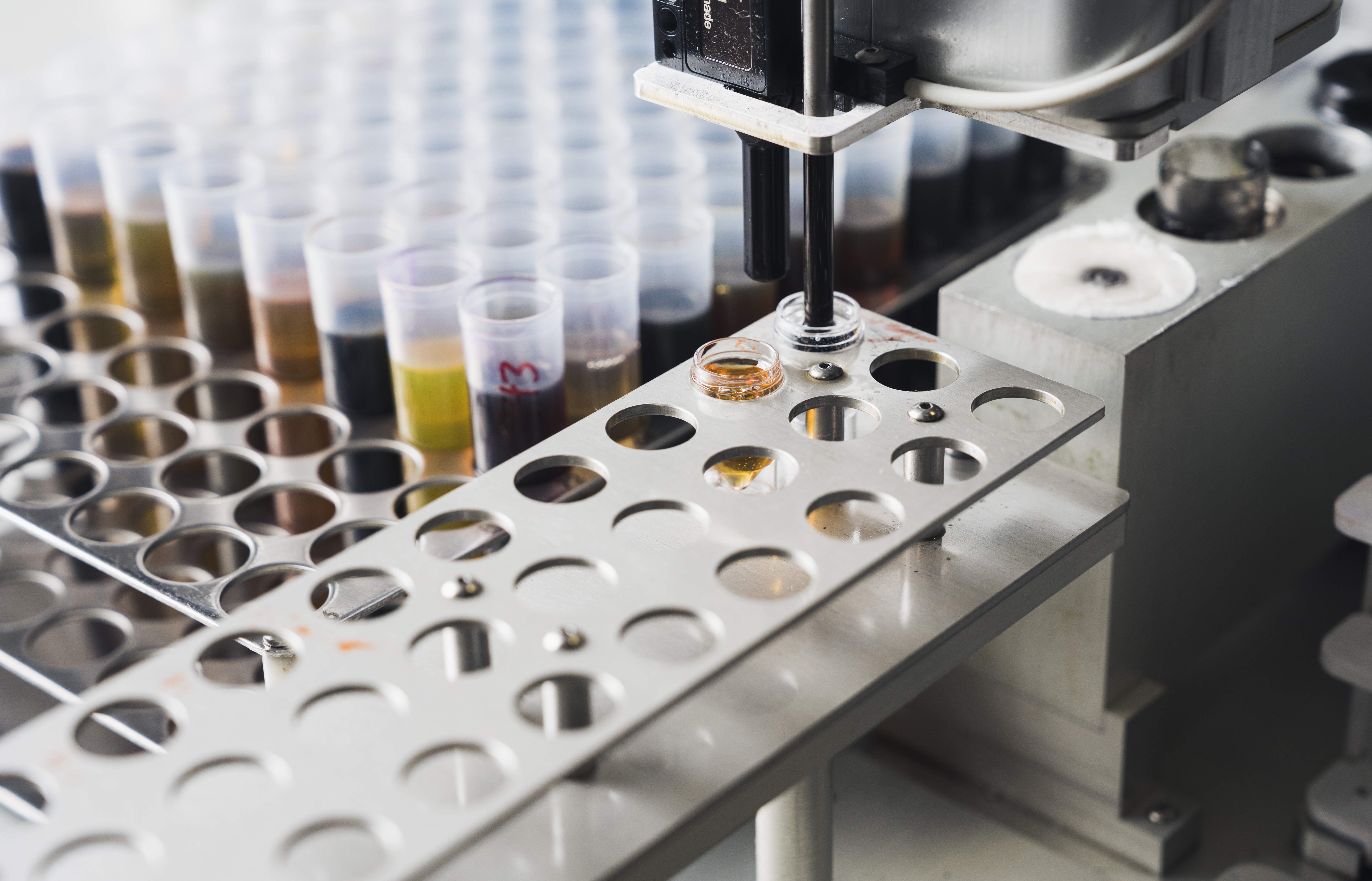

“We test used fluid samples from thousands of customers around the world for their maintenance purposes,” Mark Westlake, chief information officer at POLARIS Laboratories® explains. “Imagine a company operating heavy-duty mining machinery below ground 24 hours a day. The customer will pull a small sample of oil or coolant from their machine and ship the sample to one of our laboratory locations.” Mark continues, “we then perform scientific testing based on what analysis the customer requests. Customers are provided an electronic report that identifies results such as the presence of wear metals or conditions that indicate contamination.” The analyses performed by POLARIS Laboratories® are specific to the customer’s machinery, the fluids being used as well as the recommended component manufacturer’s wear limits.

The Project

POLARIS Laboratories® begins developing machine learning software to analyze its dataset of historical machine and equipment performance.

Over the course of almost 25 years of operation, POLARIS Laboratories® has built a massive database incorporating information from fluids, OEM machines and other manufacturing equipment. Westlake says, “customers today test fluids to understand if any conditions exist that indicate the need for maintenance, and how severe those problems are. It’s a cost/benefit balance. Customers want to extend the life of the equipment to keep capital costs down, but also want to extend the length of time lubricants can be safely used in the machine to manage operational expense. That may seem like a minor issue when thinking about the $40 to $80 cost of an oil change in a family automobile,” Mark points out, “but the industrial equipment of POLARIS Laboratories’ customers typically contains significantly more fluid. Extending the life of the customers lubricant have a noticeable impact,” Westlake says. “In addition to identifying existing problems, our software provides recommendations to customers on how far they can extend the maintenance intervals to maximize use of the lubricants while keeping the components healthy.”

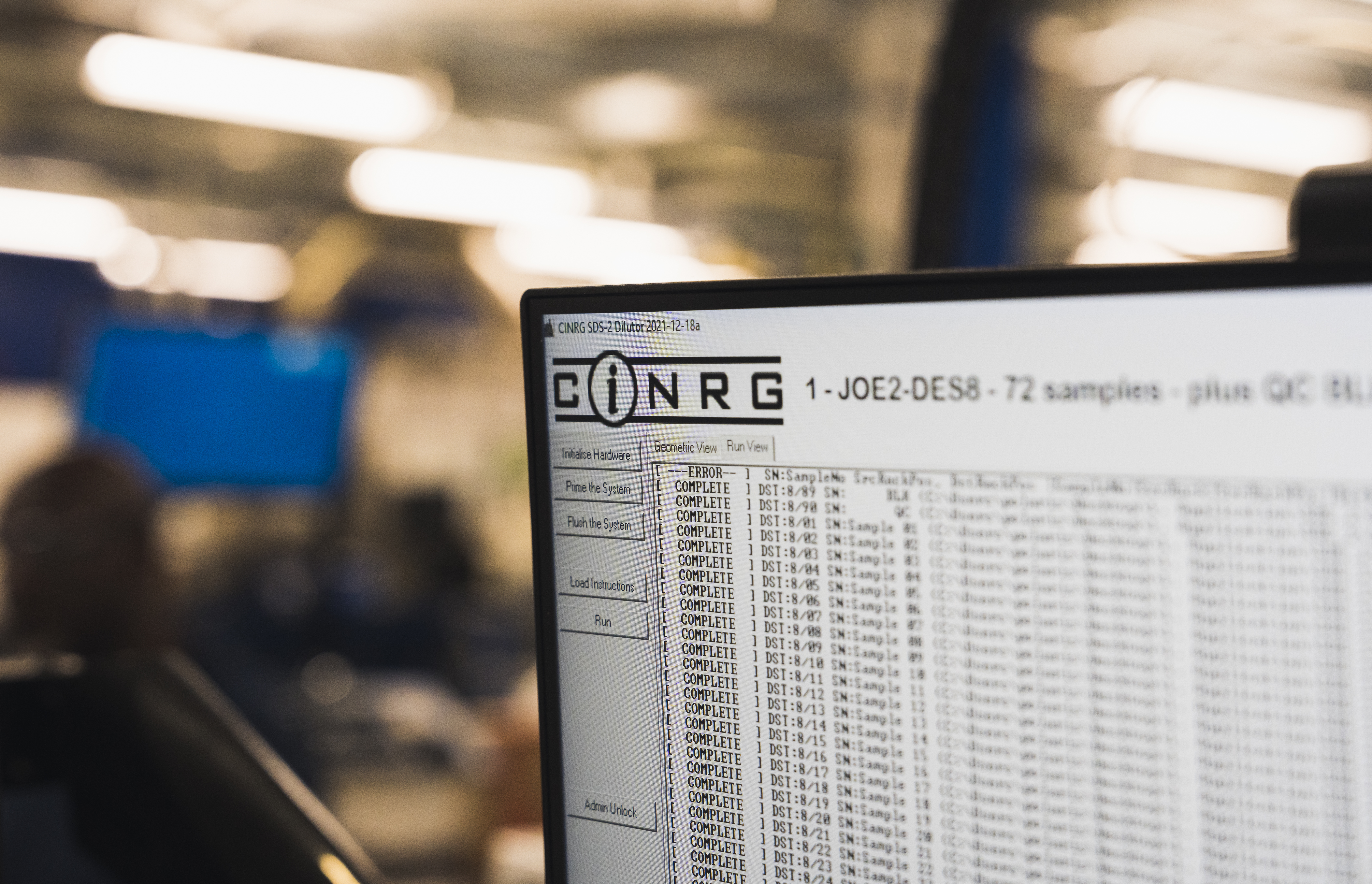

The project brings POLARIS Laboratories® existing software platforms and data together with Artificial Intelligence (AI) and Machine Learning (ML).

“Updating our existing system while operating on what amounts to a 24/7 schedule globally, has proven to be quite a challenge. I tend to make the analogy that we’re currently flying in a perfectly fine propeller-driven aircraft, but we’re converting it to jet engines in-flight. Every change has potentially significant impact on current operations.” Mark said. That’s the company’s ongoing challenge: to build new modern systems and applications that incorporate the historical data from our original software so the company can continue to experience growth and expansion of products and services.

According to Mark, the long-term goal for the company is to become a leader in predictive maintenance solutions, and to do that, real-time customer operational data must feed into the platform. “Access to telematics data is becoming more and more common with modern industrial equipment. We have many customers who have access to that data but have not leveraged it for much beyond GPS location services. Telematics data can include data points such as fuel consumption, engine temperature and load, etc. Quite literally thousands of pieces of information every hour of every day.” Most companies are not equipped to consume, store or analyze what amounts to a massive data warehouse. POLARIS Laboratories’ vision is to consume relevant portions of our customers’ telematics data and implement machine learning (ML) to identify trends and predict maintenance issues before they occur. Customers can be notified to take proactive measures to resolve problems or ask the laboratory to perform additional fluid testing to better understand the issues with their equipment.

A major step in this journey is to develop proprietary algorithms that leverage AI and ML to analyze operational telematics in conjunction with fluid analysis. Mark explains, “to achieve the vision, we must expand our architecture to warehouse vast amounts of operational data and store it on the cloud. From there, we are leveraging machine learning to marry traditional fluid analysis with operational data to build a predictive maintenance model. We are then able to monitor and identify that a component’s real-time operating conditions could lead to maintenance issues, and proactively inform our customers.”

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity. Through a grant provided by MRG, POLARIS Laboratories® invested $50,000 into proprietary software to provide predictive maintenance and analytics for its manufacturing customers around the globe.

Key Learnings

With software development and innovation, taking it step by step is crucial to get the project over the line without breaking current systems and disrupting customers.

“It would have been easier to stay with the system we know and use every day, but that would inhibit our growth and limit innovation long term,” Mark says, “we mapped out a step-by-step vision for an IT transformation and began the journey. We’ve embraced a user-centric design process and an agile software delivery methodology. Change is hard, but for those working on the project and who have migrated to new systems, the benefits are tremendous.”

The attitude at POLARIS Laboratories® has always been one of consistent incremental progress. “We’ve never been in the mode of simply saying we need to rewrite our entire software platform,” Mark said. “We take each piece and ask how we can engineer it to work while improving the specific business process. It’s an agile development cycle with the software we build. Patience for us is important, as it’s a very complicated system. We need to complete the journey without disrupting operations.” To accomplish a successful transition, POLARIS Laboratories® added two positions to its existing software development workforce to focus specifically on machine learning algorithms and predictive maintenance analytics.

Institutionalization of knowledge can be a risk for successful industry 4.0 project implementation.

One of the first lessons learned in this software project, Mark said, was the necessity to avoid institutionalizing the process. “Because POLARIS Laboratories® has been operating for more than 20 years, certain knowledge of the code within the older systems is not holistically documented. Because of this, we wanted to avoid rewriting a software platform wherein only one or two team members know what it does, but others only know ‘how’ or ‘why’ it’s done.” To avoid those pitfalls, POLARIS Laboratories® has encouraged its internal software development team to share knowledge, peer review code and document solutions so that the company understands exactly how the new platforms and algorithms are operating moving forward.

Leadership also has found an essential part of this project is to remember that while the first step of a major project can be painful, they are often worth it. “It takes time and money—sometimes more time and money than imagined. But controlled, systematic development cycles are important, and help us avoid arriving at the end discovering the result is nothing more than a rewrite of our current system,” Mark said. “In the end, I want to avoid discovering that we invested heavily in migrating away from the original visionary system developed by past software developers to something new that actually hasn’t brought efficiencies or innovation to our overall operations.”

“We are leveraging machine learning to marry traditional fluid analysis with operational data to build a predictive maintenance model.”

Mark Westlake

Chief Information Officer at POLARIS Laboratories