TBK America Invests in a Product Traceability System to Reduce Customer Risk and Enhance Internal Processes

TBK America

Case Study

Key Stats

Company History

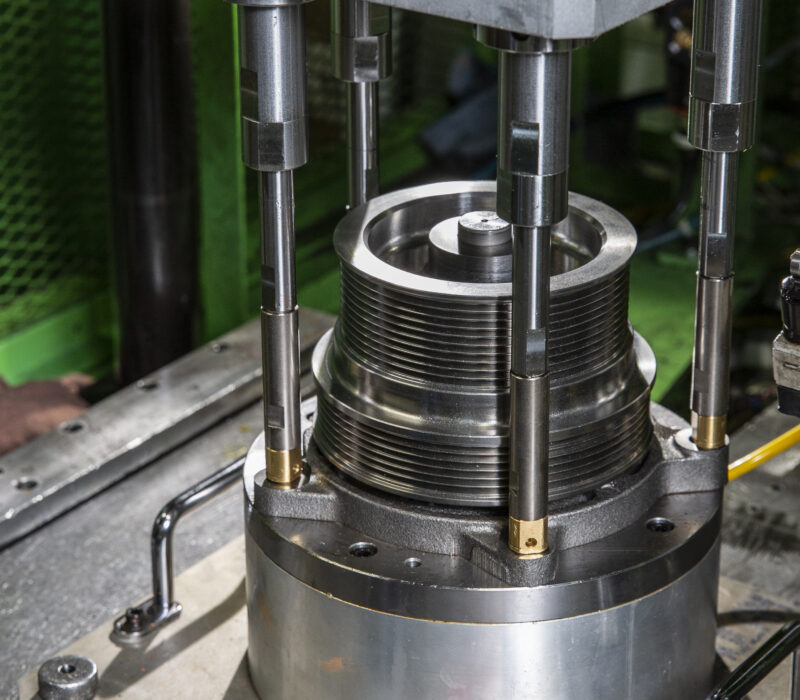

TBK America: Manufacturer of water pumps and lube pumps for the automotive industry.

TBK America is part of a global company established in 1949 and headquartered in Tokyo, Japan. It has manufacturing facilities throughout Asia, including in Thailand, China and India. TBK America’s U.S. operations are in Richmond, Indiana, where the company was planted by its Japanese parent in 2002. When it was opened, the Richmond plant focused on manufacturing water pumps for a largely commercial customer base of over-the-road semi-trucks and other vehicles in the automotive industry. In 2017, TBK America expanded into manufacturing lube pumps.

The Project

From the factory floor to customers and the end-consumer, implementation of a traceability system will create value throughout TBK America’s supply chain.

TBK America’s application was initially based on requests from one of the company’s largest original equipment manufacturing (OEM) customers to help reduce customer risk by incorporating a traceability system into its manufacturing process. While traceability has been a major concern in the aerospace and medical industries for some time, it hasn’t yet become an absolute necessity in the automotive industry. And in response to one of its major customers, TBK America began working to develop a system that would identify each machine and assembly component through a unique “Q” code incorporating sensors. The code is attached to each part in the form of a bar code, much like those seen in grocery stores and other retail businesses. The sensor’s primary purpose is to identify each product part as they move through the production process. The system can even stop the assembly process until that part is exchanged for the correct part or, in the case of a faulty component, is replaced with a non-defective part.

A second value-add to the new system is the precision of the on-site traceability after the product is delivered to the customer. Should an issue arise with the assembly after it is put into production by the customer, the part can be traced so precisely that it can identify more than just product parts. “We can see what machine it was built on,” said TBK’s Senior Production Manager Brian Claywell. “We can even identify what shift it was built on, down to the exact date and even minute it was built.”

Embarking on a major improvement to its manufacturing operations, TBK America decided that expanding the traceability project into other areas of the business made sense. TBK has since created a robust inventory of digital records that before had been paper-based. Now, the company’s quality department uses data drawn from the traceability system to measure overall reliability of its products and to communicate that data with customers. Much of the data can also be used to forecast demand and material planning, and ultimately help the company be more efficient.

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity. TBK America’s successful MRG application provided funds towards a project to help reduce their customers’ risk and improve internal processes.

Key Learnings

TBK America’s workforce was upskilled and trained on the new systems, workflows and practices.

One of the biggest changes for TBK America’s workforce was learning to allow the system to “do the work.” New systems affected major assembly lines and all machining lines, and that meant virtually everyone needed to be trained. TBK led internal staff training so production workers could adapt to the new technology. That included rewriting work instructions and change-over checks and a complete documentation overhaul. Engineers led “train the trainer” sessions to enable an in-house training staff educating operators to learn new work tasks and functions.

All of that took six weeks and significant “trial and error” periods to smooth out the processes so that everyone felt comfortable with the new systems. But perhaps the most important skill the trainers needed to pass on to operators was a tech-driven mindset to leverage the new systems, workflows and practices continually.

The technology adoption project enhanced production efficiency.

In the year since the project went live, the change-over time has been reduced by 30%. Because the new sensor technology does not allow assembly lines to run if part numbers or pieces are incorrectly entered, it doesn’t take long for assembly operators to realize errors—since the line stops for such errors, operators can quickly recognize the root of the problem and are able to rectify it.

But one of the biggest successes for TBK was the realization that the cost and effort of creating and implementing the product traceability system will show benefits for years to come. Tricia Grams, the company’s senior finance and ERP manager, pointed to the ability of executives and managers to make decisions more quickly because of the data now generated. She looks toward a future with real-time product and quality data and highly digitized operations. “I keep saying I’m working for the future of TBK,” Tricia said. “This project will make all our lives easier.”

“I keep saying I’m working for the future of TBK. This [technology adoption] project will make all our lives easier.”

Tricia Grams

Sr. Finance & ERP Manager at TBK America