Nonprofit amps up Indiana’s battery industry by empowering entrepreneurs, aiding established players and training workers

Greene County organization seeks to accelerate battery innovation

A unique nonprofit in the heart of Greene County’s green expanses is serving as the center of the universe for Indiana businesses working to stake a claim in the quickly expanding battery marketplace.

Located in Newberry, Ind., the Battery Innovation Center (BIC) offers services to everyone from college professors with high-tech discoveries to Fortune 500 companies with products to test, and from entrepreneurs looking to manufacture their inventions to military departments seeking to sharpen the cutting edge. And, unlike many similar organizations, BIC provides its services without taking a cut or equity position in companies or technology it assists. Instead, it operates as a nonprofit supporting battery-related businesses as a means to strengthen Indiana’s economy.

Seeking to accelerate battery innovation to drive industry expansion, BIC provides everything from product R&D to low-volume manufacturing space in a 36,000-square-foot facility near Naval Surface Warfare Center Crane and ancillary space in Indianapolis. Its structure these activities on three pillars:

More than 500 customers have turned to BIC for services over its 12 years, ranging from established automotive and heavy-equipment companies to start-ups and companies working alongside the energy-supply grid. BIC has trained some thousands of individuals in various areas of the industry – from battery fundamentals to high-voltage training – and helped its customers improve battery life and safety, advance cell technology, lower battery costs, leverage new materials and more. Alexander sees only growth opportunities ahead. As electric vehicle (EV) and hybrid cars claim bigger shares of sales (the EV market is at a 15%-per-year growth rate), auto manufacturers are shifting resources to electrification efforts and small companies are pursuing niches as industry suppliers.

Meanwhile, mobile power sources are picking up steam in other segments, sparking ongoing innovation and entrepreneurial energy, and grid power initiatives also are booming.

Recent news has linked Indiana to big battery-industry investments and potential investments from the federal government and corporate interests. Most notably perhaps, last fall the Department of Energy loaned Entek Lithium Separators LLC $77 million to build a battery separator plant near Terre Haute, just a couple of months after Clarios announced that Indiana is in the running for a $1 billion critical minerals processing and recovery plant.

“It’s a very dynamic and evolving thing,” Alexander says. “There’s been a tremendous improvement in battery technology in a very short time, and I think we’re still at the tip of the iceberg.” This expansion is reflected in BIC’s work: The team took on more than 20 new clients in 2025, Alexander says, and they’re typically working on 18 to 25 projects a month.

A challenging landscape

Offering such a broad range of services to such a varied audience comes with challenges, including one that could seem counter-intuitive, given the growth in the battery marketplace: In recent months, demand for BIC’s services has slowed. However, Alexander is not too troubled by this, as he attributes the slowdown in part to shifting priorities within the federal government and expects the lag to be short-lived.

A second challenge could be more enduring: More organizations are offering services like BIC’s, including universities that are getting into the battery-development business. Alexander believes BIC has built-in solutions to this challenge: With no university affiliation, it offers entrepreneurs more freedom and, with no equity claims on intellectual property, it allows its clients to keep more of the return on their investments.

However, this model brings its own challenges: Taking a backseat on projects and their returns also means assuming a lower profile. As a result, BIC doesn’t get a lot of buzz from its work, which means a lot of people and organizations that could benefit from it might not even know it exists. Alexander believes this challenge will also find resolution as the organization helps more firms hit their stride.

Of course, Indiana isn’t the only place trying to stake a claim in the battery industry landscape. The production and development of battery technology is an international competition, with the U.S. and China squaring off in the pursuit of battery materials and the chemistries that make batteries work. At the same time, neighboring states are investing in battery development projects.

At the heart of many of these efforts is the race to discover, develop and process battery materials that can produce energy more cheaply, safely and sustainably. Alexander notes that, in many ways, the U.S. is playing catch-up in this area. Although much of the science behind batteries was developed in the U.S., in the past manufacturers found better production terms in China and other Asian locations. Now the U.S. is trying to win that business back through government, academia and industry efforts to discover new options and improve battery science and the manufacturing process.

Not only does this help place Indiana and the United States on equal footing, but it addresses national security and supply chain concerns too. As we all experienced during the COVID-19 pandemic, there can be significant logistical problems experienced in a highly globalized economy. Reshoring critical elements of American manufacturing helps us become more competitive and insulated from external variables outside our control. This has obvious national security implications as well, especially when global partners become potential adversaries. Not only are consumer products affected, but American military products as well. The BIC remains committed to helping the US military solve its own challenges with providing power to the technology that helps protect our country. Among the most pressing topics now is drone development, something the Indiana Congressional Delegation and Governor have identified as a priority. Often, certain products’ technology can outpace current battery technology, hindering the effectiveness of a given product. With its connections and proximity to Crane, BIC believes it is well positioned to help solve these types of complex problems in the industry.

By giving Indiana-based scientists the space they need to innovate and develop new materials and make them marketable, the state has the opportunity to put more of its workforce to work creating products based on those materials. BIC plans to act as a catalyst in this process with its location in the Emerging Manufacturing Collaboration Center (EMC2) in Indianapolis’ 16 Tech Innovation District, which is envisioned as a place where companies can move from the R&D phase into small-scale production.

“We’re trying to create that manufacturing environment at EMC2 so customers, after they move out of our research-and-development capability, can go into mid-stage manufacturing,” Alexander says. “Then they can actually have samples to give customers, do full testing and evaluation of their materials, and then be able to get financing to move into their own facility and, hopefully, stay in Indiana.”

Indiana’s strength in advanced manufacturing also can help in this area, Alexander says, by focusing some of its expertise and productivity on the battery market. “We have to create those new manufacturing techniques and processes that would cheapen the batteries or level the playing field as compared to Asian counties,” Alexander says.

Of course, Indiana’s battery industry hasn’t avoided the workforce challenges that dog all of manufacturing, but BIC is helping the state meet that challenge. In this effort, it works from the ground up, familiarizing Hoosiers with batteries and the opportunities they present. BIC is participating in a Department of Energy Battery Workforce Challenge, which drives STEM education for kids and adults, and it also has put a special emphasis on engaging veterans in the battery industry and the employment opportunities it presents.

To help workers see these opportunities and take advantage of them, BIC provides training for workers seeking to enter the industry, upskill or reskill. The organization will partner with employers to provide customized training but also offers community-based training sessions, such as its Energy Storage Short Course, which starts with battery fundamentals and builds from there. In the last half-dozen years, Alexander says, BIC has trained more than 1,500 people.

Through all of these efforts, BIC is hoping to strengthen the overall battery industry in Indiana and attract companies to the state. In this regard, it’s already seen success. “We’ve been instrumental in bringing some of the battery industry to the state of Indiana,” Alexander says, “and we feel like we’re a service to the community and a very valuable asset not only to the state but to the country.” Among those big players who were attracted by BIC is Underwriters Laboratories (UL), which 10 years ago moved its North America testing and validation for large batteries and energy storage systems to Greene County.

Key Learnings: Fail well, learn from mistakes and pivot when the market dictates

The Battery Innovation Center has found that building a better battery industry requires a fair share of base knowledge and more than a few failures. By combining those components with the entrepreneurial spirit and the right resources, BIC believes Indiana can be a major player in the mobile-energy marketplace. Following are some lessons the team has learned as it has pursued that goal.

Help people understand your industry. People have become so accustomed to having batteries around that they take battery science – the required chemistry, chemical engineering, electrochemistry and so on – for granted. Reminding people of batteries’ complexity is necessary to build up the battery industry and workforce in Indiana, Alexander says.

Fail with a purpose. When BIC tests products for its customers, it doesn’t just hook them up to monitors and watch them function normally. It pushes them to the limit, puts them in extreme conditions and then delivers data to the customer. “We have a chamber to actually abuse the batteries, to make them fail so they understand how the battery can fail safely,” Alexander says.

Learn from mistakes. Alexander has been working in the battery industry since the late 1990s, and he says he’s seen the industry and companies go through a lot of ups and downs. “I’ve learned from both successes and mistakes,” he says. “I’m trying to pass that on to the community so that we don’t make the same mistakes again.”

Be ready to pivot. A few years ago, it looked like EVs were going to own the road in a short time, but political shifts and consumer hesitation – most notably around what Alexander described as “range anxiety” – shifted the emphasis to hybrids. BIC has adapted, not fully taking its eye off the EV market but making sure it helps hybrid-focused product developers as well.

“With us, you get experiences R&D teams that have looked at multiple problems from multiple areas, and we can lean into our experience to actually accelerate development. I won’t say that we’ve seen it all, but we’ve seen quite a bit.”

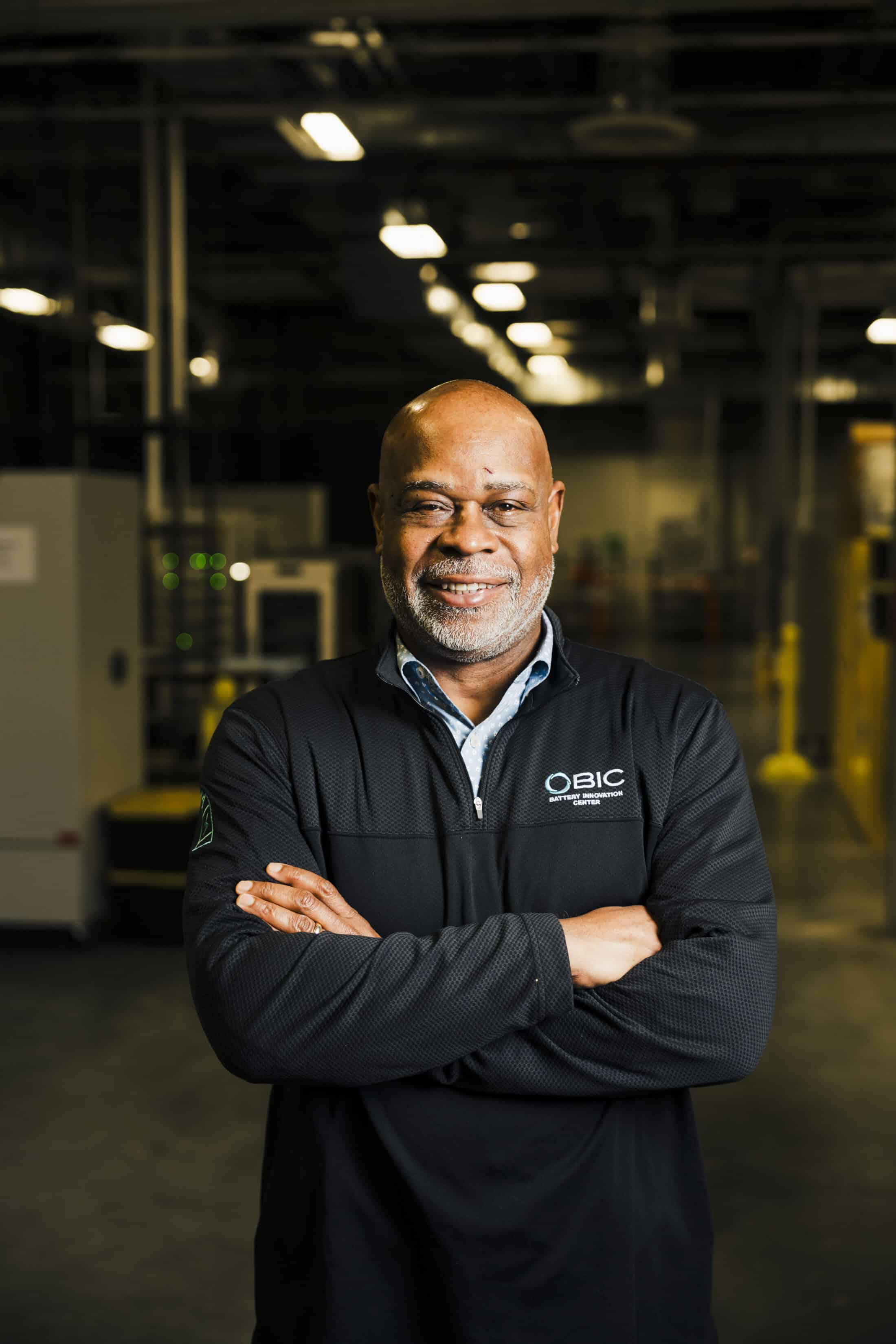

Les Alexander

CEO, Battery Innovation Center