Cimtech Inc. Leverages a Manufacturing Readiness Grant to Adopt First-to-Market Smart Manufacturing Technology for Enhanced Quality Control and Improved Manufacturing Efficiency

Company History

Commercial banker Jesika Young was eager to exercise her entrepreneurial ambitions, and her experience and research told her manufacturing would be the ideal fit. She and her husband, Jerod, had returned to their southern Indiana roots in 2012. A few years later, the Youngs met Anne Pfeiffer, who was contemplating the sale of her 43-year-old manufacturing company specializing in precision-machined parts, fabrication, assembly, sub-assembly, engineering and design. “My husband and I always wanted something of our own and went down every path you can imagine—franchising, starting a service or consulting firm,” Jesika said. “Then the bank I worked for was bought out, and I thought ‘here’s the kick we needed.’ It took us 9 months to take our acquisition across the finish line, and in July of 2018, we closed on Cimtech Inc.”

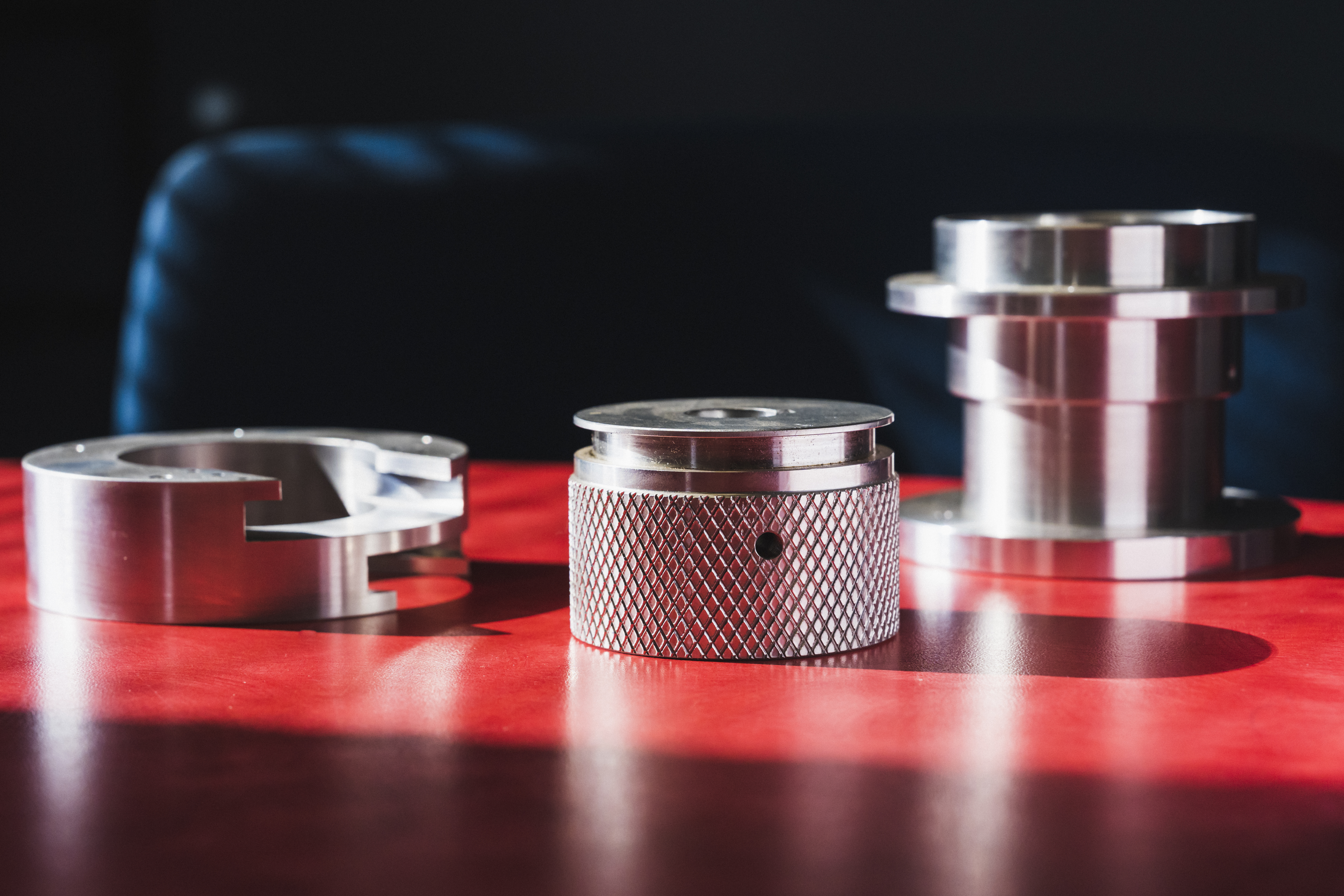

The company was located in the heart of southern Indiana, in an industrial park just 15 minutes from the Youngs’ home in Floyd Knobs. Both Jesika and Jerod had grown up in manufacturing homes, with fathers who were tradesmen. “We know that everything we do or touch comes from either a farm or a manufacturer,” Jesika said, adding that the custom parts and components Cimtech makes are found in all sorts of name brands across the country. “Get a drink at Taco Bell or McDonald’s, or almost any restaurant that has fountain drinks; we’ve been making parts and components of those machines since 1984.”

Over the next few years, the Youngs’ expanded the Cimtech family, adding additional capabilities and land around the Cimtech headquarters. The company now owns the entire cul-de-sac in the industrial park in preparation for growth and new equipment additions. Jesika explained, “the purchases are part of our intent to grow our campus here in Indiana. Continued growth here is important to us; almost 90% of our team members are Indiana residents.” Along with promoting Indiana, she’s also eager to encourage more women to enter the manufacturing industry. “Less than 4% of manufacturing firms across the United States are women-owned businesses. We need to get the message out there that advanced manufacturing and logistics are good businesses for women to get into.”

The Project

“It wasn’t long after we acquired Cimtech Inc. that we realized we needed to bring new smart technology to the table,” Jesika recalled. “We had passed on several opportunities from customers, and that gave us that ‘aha’ moment. We could either develop a strategy for a niche market or invest in new technologies enabling us to go where the market was moving. That’s the direction we took.” The goal was to take a 13-step operation down to 3 steps by adding 5-axis machining. An internal team of master machinists, engineers, the operations manager and the Young’s investigated new equipment that could offer those abilities.

“We found a local company, Meredith Machinery in Louisville, that had developed a 5-axis milling center called a ‘micro dynamic’ machine. When we first saw it in operation on the showroom floor, it was milling out a titanium kneecap for knee replacement.” Jesika continued, “The machine can hold extremely tight tolerances, down to the micron. The fact that it has those capabilities, and it’s new to the market was exciting. And I can also claim that Cimtech is one of the first Indiana companies to procure this type of machine.”

This particular machine’s design was significantly different from other 5-axis machines on the market, producing ideal finishes for aerospace, medical and dye molds, as well as any general-purpose operation. “We knew it would make a great addition to our existing capabilities,” Jesika said. Two major selling points for Cimtech was (1) the micro dynamic milling machine has coordinate measuring machine (CMM) capability integrated into one package to help assist Cimtech in its quality checks and (2) the machine provider, Meredith Machine, offered support of its nearby experts to assist with any issues or programming questions. Jesika further highlighted this as a key selling point with the machine being new to the market.

Manufacturing Readiness Grants provided by the Indiana Economic Development Corporation (IEDC) and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity, efficiency and productivity. Cimtech Inc. leveraged its $50,000 Manufacturing Readiness Grant to Adopt New Smart Manufacturing Technology for Micro Dynamic Milling at its New Albany, Indiana, headquarters.

Key Learnings

“Probably the biggest lesson I learned from that first MRG application was to embrace the process,” she advised other Indiana manufacturers. “The process helped us avoid making a faster decision, and one that in retrospect would have been the wrong decision. In the end, the grant funding helped us procure the micro dynamic milling machine, and it also provided the encouragement and incentive to look beyond the surface and push the envelope of what we thought was possible. It was the right decision for us and the results we are having with this machine prove it.”

Jesika shared how her original projection of a $300,000 annual revenue boost from the new machine was met in the first 5 months of operation. “It doubled our growth projection in less than half the time,” she reported. “I couldn’t be more pleased with that result. Plus, by reducing that 13-step operation down to just 3 steps with quality checks included in it, we were able to increase quantity and quality delivered to existing customers.”

When Jesika and Jerod purchased Cimtech Inc., they inherited a loyal workforce with an average tenure of 20 years at the company. They had no opportunity to inspect the company within the 4 walls of the physical facility prior to inking the final purchase papers so how they introduced themselves was key to making the transition as smooth as possible for the employees. “Of course, there was some hesitancy among the team members,” Jesika admitted. She began by explaining her philosophy to the staff: “We’re a team first,” she explained. “We lead by a completely different motto. We’re part of the team; no one recognizes us as the ‘owners.’ In fact, the first thing we changed was everyone’s signature line. My business card identifies me as ‘Team Member & President/CEO’. And now individual titles begin with ‘Team Member’ followed by their department and job.”

Establishing that mindset has been rewarded not just with the MRG funding, but in 2020—just 2 years after the purchase – the team was nationally recognized as one of the top 10 manufacturers in the United States by “Manufacturing Insights Magazine.” “We’ve garnered some fantastic recognition and our reputation is that we provide great quality products in collaboration with our partners,” Jesika said. “Our team should be proud of what they’re doing, and the ability to tell that story has been magic. The fun part of my job is that I get to brag about our team. They’re phenomenal.”

One of the ways the Youngs’ demonstrated that philosophy was by developing an internal team to determine the first step in adopting new smart technology. When the initial application didn’t win a Manufacturing Readiness Grants award, that same team went back to the drawing board and developed a plan centered on the purchase of the new-to-market Meredith Machine.

“It [the new production equipment] doubled our growth projection in less than half the time… We’ve been able to increase quantity and quality delivered to our existing customers.”

Jesika Young

Team Member, President & CEO at Cimtech Inc.