As advanced manufacturing and logistics (AML) companies integrate robotics, automation, and artificial intelligence into their operations, these conversations often begin around technical capabilities like speed, precision, and cost reduction. For long-term success, an equally important consideration is the relationship between these systems and employees. This concept of Human-Machine Interaction (HMI) plays a critical role in sustainable and successful technology adoption.

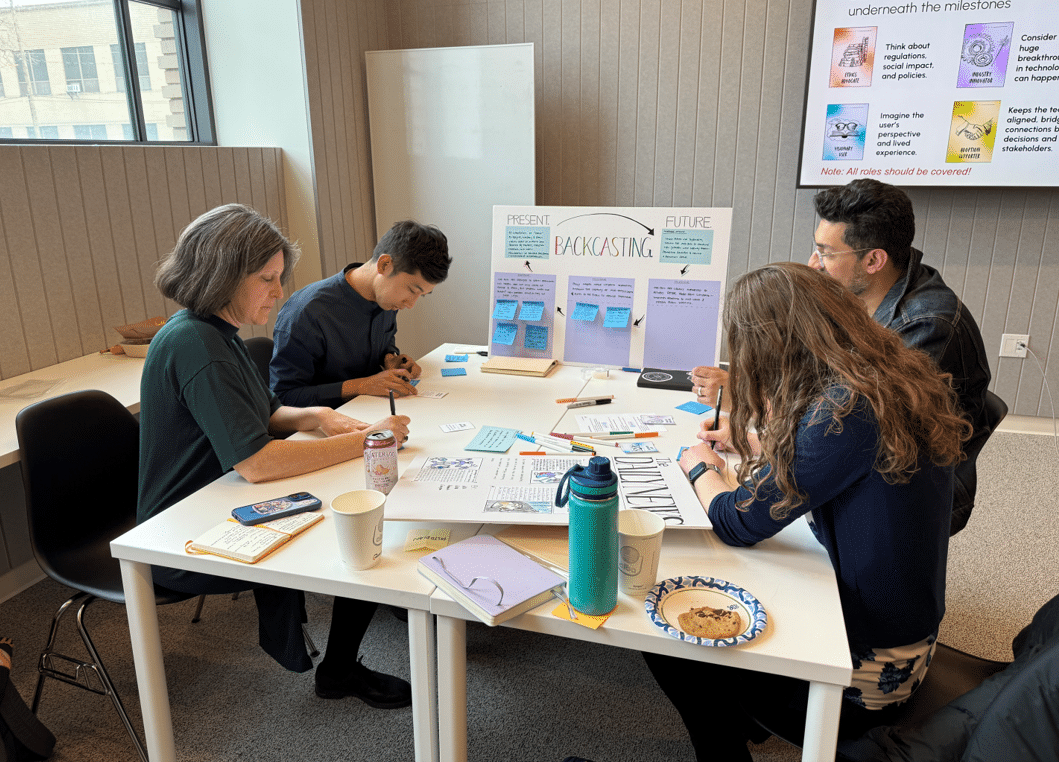

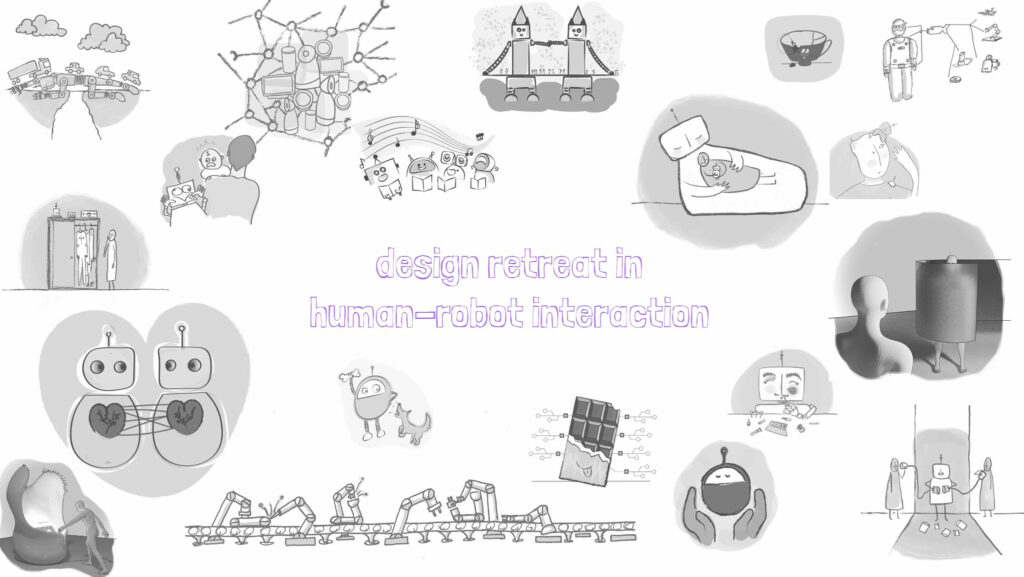

In April 2025, Anastasia Kouvaras Ostrowski, Assistant Professor in the School of Applied and Creative Computing with a courtesy appointment in the School of Mechanical Engineering at Purdue University, and Patrícia Alves-Oliveira, Assistant Professor of Robotics at the University of Michigan, organized a 2-day Design Retreat to explore the future of HMI – inviting global experts from academia and industry to create a roadmap of critical areas that will drive future efforts in this field. The Conexus Indiana team reached out for context on how these workshop findings and the concept of HMI should be an active consideration for the AML industries.

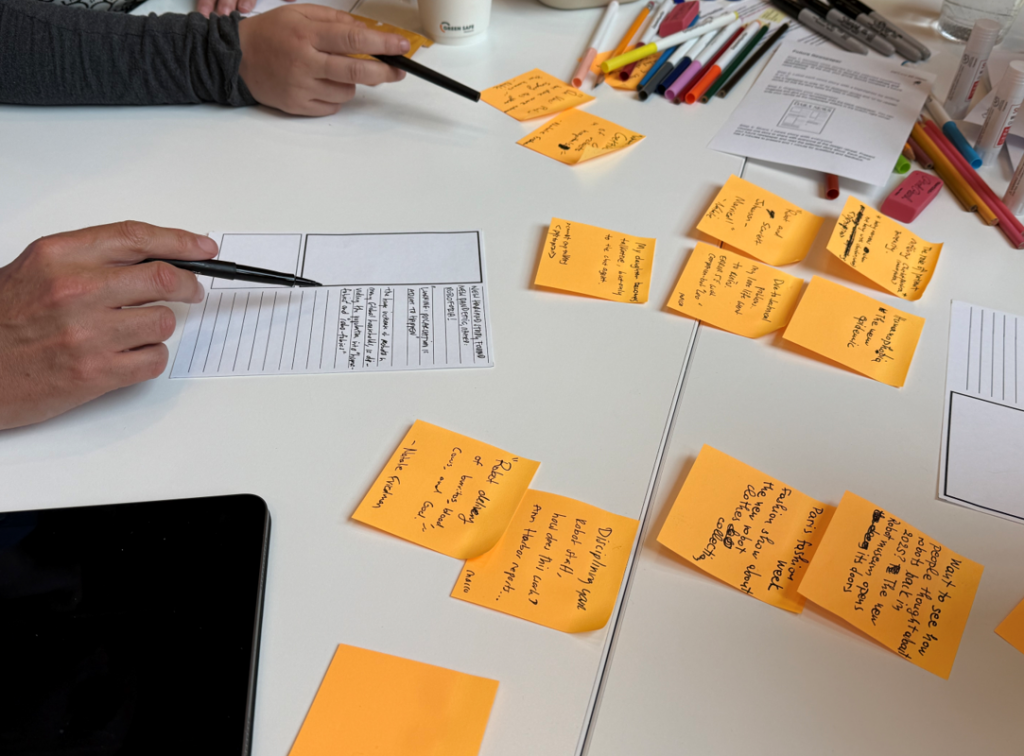

HRI Design Retreat Documentary | Design Retreat Activities and Materials

Takeaways for AML:

From Josh Rychtarczyk, Director of Strategic Insights

AML Sits at the Intersection of Technology and Society

Advanced manufacturing and logistics environments are not purely technical spaces – they are sociotechnical systems where humans and machines continuously influence one another. As Anastasia notes, “People have an innate capacity to unconsciously treat robots and systems as social agents – assigning them meaning, intent, or personality” – a dynamic that directly influences how employees will behave around, adapt to, and trust automated systems.

In practical terms, this means that machines don’t just need to function well, they need to communicate well with the people around them. Workplace technologies that behave predictably and transparently will improve integration timelines as well as a workforce’s potential presumptions around automation. Bringing these considerations to conversations around technology adoption in AML is a critical part of a company’s technology adoption journey.

Safety and Situational Awareness

HMI plays a central role in keeping operators safe around automated equipment. Interfaces that clearly communicate machine actions and intentions help workers anticipate behavior, avoid hazards, and make better decisions.

Efficiency and Operational Intuition

Productivity gains that automation can provide are either restricted or enhanced via the quality of human-machine interaction. Clear, intuitive design choices reduce an operator’s mental load and accelerate technical skill acquisition. Machine interface quality should be an important consideration when evaluating new technologies; when operators understand what the machine is doing and why it’s doing it, they can act with confidence.

In addition, forward-looking organizations are exploring technologies beyond traditional robot designs and interfaces. Form factor matters: movement, sound, position, and behavior all influence how employees will interpret machine intentions.

Trust and Adoption

A workforce’s trust in technology emerges from predictability and experience. “Trust isn’t about believing machines are infallible; it’s about knowing when and how humans can intervene effectively,” mentions Anastasia. Human-centric interfaces, thoughtful training and an early introduction to automation concepts will help cultivate this trust and encourage employees to engage with technology, rather than avoid or resist it.

Machines as Complements, Not Replacements

Automation can absorb physically strenuous or repetitive tasks – but it rarely eliminates the human role entirely. Instead, automation reshapes jobs toward more cognitive, supervisory, and high-value work. Operators become monitors, interpreters, and collaborators with machines. This dynamic is central to how HMI creates value: it enables humans to augment their capabilities with machines, rather than be replaced by them.

HMI in Emerging Technologies

Several emerging technologies are redefining what HMI can look like in AML settings:

- Artificial Intelligence (AI) – Generative AI (GenAI) and advanced analytics are enabling more adaptive, context-aware interfaces that can communicate in familiar ways (e.g., predictive insights that are presented in natural language).

- Augmented and Virtual Reality (AR/VR) – These immersive environments can accelerate training, reduce risk exposure during hands-on learning, and proactively involve a workforce with a business’s technology upgrades.

- Cyber-Physical Systems – Digital twins and real-time feedback loops are creating new learning ecosystems where humans and machines adapt to operations together.

Ecosystem Support: Organizations Advancing HMI

There are several ecosystem partners that offer resources, training, and research support for HMI in the world of AML:

Clean Energy Smart Manufacturing Innovation Institute (CESMII) – Part of the Manufacturing USA network, CESMII works with partners to accelerate smart manufacturing adoption, offering learning systems that can benefit HMI-related transformation.

Michigan Manufacturing Technology Center – As a NIST MEP-approved center, MMTC helps manufacturers adopt Industry 4.0 technologies that include enhancing human–machine interaction as part of broader automation and digital strategy.

International Society of Automation (ISA) – A global professional association advancing automation standards and practices, including human-machine interface standards to promote safer and more intuitive interaction design.

IEEE Systems, Man, and Cybernetics Society – A technical society focused on human-machine systems research that bridges engineering, cognitive ergonomics, and systems science.

Academic HMI/HCI Research Groups – Organizations like the University of Maryland Human–Computer Interaction Lab and SIGCHI (Special Interest Group on Computer–Human Interaction) help advance foundational knowledge in how humans interact with complex systems, including manufacturing interfaces.

Looking Ahead:

Human-Machine Interaction will only grow in importance as automation scales across shop floors and supply chains. We can expect:

- Increased need for interdisciplinary HMI implementation teams

- Workforce training programs tied to fluency in human-machine interactions

- HMI to emerge as a core capability in digital transformation strategies

- Continued collaboration between industry and research ecosystems to co-develop best practices for HMI

Interested in Exploring the HRI Design Retreat Activities More?:

During the Retreat, participants completed 4 workshops that support envisioning the future of HRI Design. You can find these materials open-sourced and available on the Design Retreat’s website. These workshops can help support you and your organization in considering how HMI could be incorporated into your workflows through unique, forward-looking activities.

The Bottom Line:

Organizations that intentionally prioritize HMI in their technology adoption and workforce development strategies will be better positioned to unlock gains in safety, productivity, and workforce engagement.