Ready for the Future

Our Manufacturing Readiness Grants are helping Indiana’s makers meet the challenges of a rapidly changing economy. Explore their stories.

Catalyst PDG Takes Bold Steps to Increase Its Contract Manufacturing Capabilities with Support From a Manufacturing Readiness Grant

Lumatic Imagery LLC Wins Manufacturing Readiness Grants Scale-Up its Manufacturing Production for PopCam

2 Applications, 2 Projects, 2 Manufacturing Readiness Grants Take Creative Works to the Next Step in its Digital Manufacturing Journey

A&A Custom Automation Invests in Additive Manufacturing for Production Parts to Reduce Costs and Streamline its Subtractive Manufacturing Processes

Addman Engineering Leverages Manufacturing Readiness Grant to Secure Next Generation Metal Additive Manufacturing Equipment for Production

Manufacturing Readiness Grant Spurs Growth for Complexus Medical and Opportunities for its Workforce

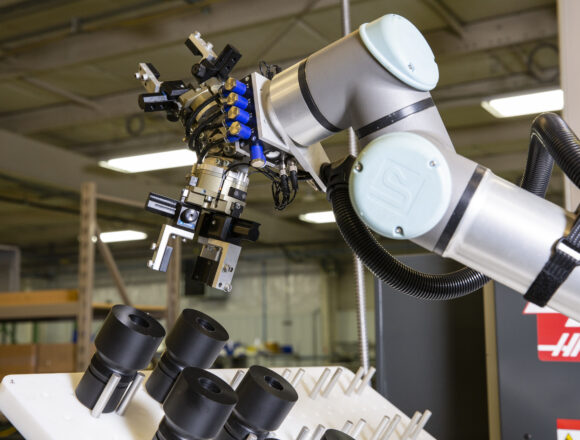

Batesville Tool & Die Invested its Manufacturing Readiness Grant in Advanced Robotics with Integrated Machine Vision to Significantly Grow its Manufacturing Capacity

A Fully Integrated Automation Line Becomes Reality at Chiyoda USA with Support from a Manufacturing Readiness Grant

Oscar Winski’s manufacturing story began with opening his first scrap metal business with his son, Louis, in Lafayette, Ind., in 1907. Today, that company retains its original entrepreneurial spirit, with […]

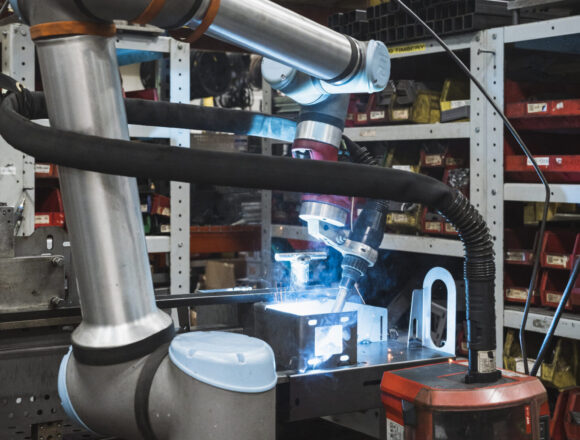

Soil-Max Implements an Innovative Robotic Welding System to Create a Dynamic Manufacturing Process

Batesville Tool & Die Invested its Manufacturing Readiness Grant in Advanced Robotics with Integrated Machine Vision to Significantly Grow its Manufacturing Capacity

Photon Automation Develops and Deploys a Proprietary Fiber Laser Welding System for Assembly of High Energy-density Batteries Used in Next-generation Transportation, Telecommunications and Consumer Products

POLARIS Laboratories® Invests in Proprietary AI/ML Software to Provide Predictive Maintenance and Analytics for Its Global Manufacturing Customers

Mach Medical Develops a Digital Twin Solution for High Velocity Single-Piece Flow Manufacturing

117-year-old Pike Lumber Company Continues Legacy of Sustainable Forest Management and Tech-enabled Sawmill Operations with Help from Manufacturing Readiness Grant

Digital Wood Carver Implements a Collaborative Welding System with Support of an Indiana Manufacturing Readiness Grant

Telamon Corporation Leverages a Manufacturing Readiness Grant to Deploy Collaborative Robots for Assembly Line Automation in its Carmel, Indiana, Plant

Wood-Mizer Takes the Next Step in its Automation Journey, Adding Innovative Collaborative Welding Systems to Automate its Low-Volume, High-Mix Applications

Arcamed Leverages a Manufacturing Readiness Grant to Implement Two Cobots and the World’s Fastest Small Part Bending Cell

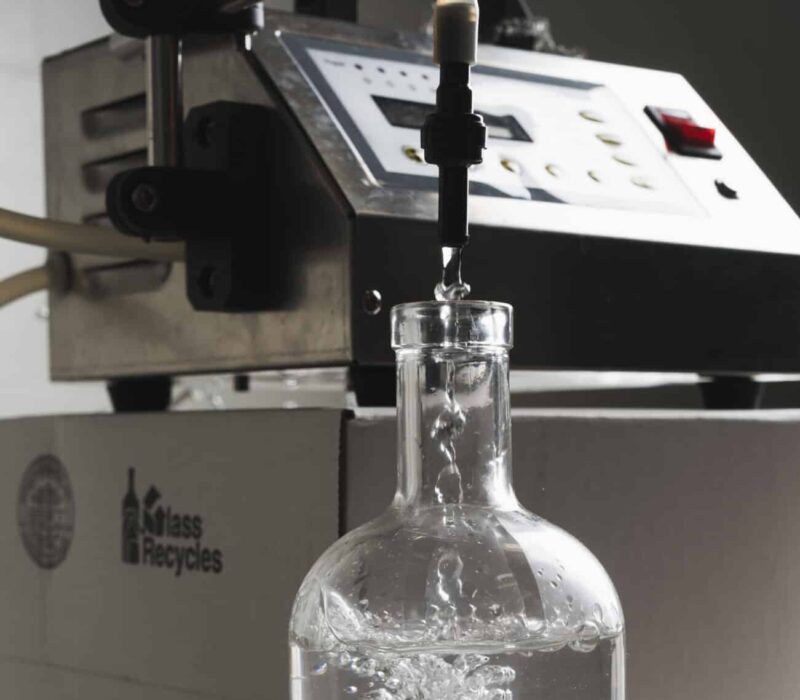

Entrepreneurial Winemaker Earns Manufacturing Readiness Grant to Expand Business with Automated Technology

TBK America Invests in a Product Traceability System to Reduce Customer Risk and Enhance Internal Processes

TouchTronics Invests in New Equipment to Enhance Product Quality and Bring Product Testing In-house

Marion Manufacturing Increases its Competitive Edge by Digitizing Product and Quality Inspection Data

D.A.S. Services Embarks on a Digital Manufacturing Journey with Innovative, Industry-Specific Software for Repair Shops

Young Entrepreneur Tapped $200,000 Manufacturing Readiness Grant to Help Bring Smart Tech to His AgTech Start-up

Hardtech company, MITO® Material Solutions, scales up production of its proprietary manufacturing additive materials with investments from Indiana VCs and a Manufacturing Readiness Grants award

Social Impact Company, Crossroads Solar, Invests in an Automated Assembly Line for Solar Panel Production

Brinkley RV Launches a New Range of RV Products, Manufactured in Its Newly Built Production Facilities with Integrated Smart Tech

Lumatic Imagery LLC Wins Manufacturing Readiness Grants Scale-Up its Manufacturing Production for PopCam

Manufacturing Readiness Grant Spurs Growth for Complexus Medical and Opportunities for its Workforce

Social Impact Company, Crossroads Solar, Invests in an Automated Assembly Line for Solar Panel Production

Brinkley RV Launches a New Range of RV Products, Manufactured in Its Newly Built Production Facilities with Integrated Smart Tech

Lippert Makes Large Investment in Automation to Upgrade its Bristol Facility with Support of a Manufacturing Readiness Grant

$2 Million of Investment in New Tech Capabilities and a Strong Business Case Earned Hammond Machine Works a Manufacturing Readiness Grant