Choosing to be great instead of giant, Jeco Plastic Products focuses on precision when others chase volume

Jeco Plastics

Key Stats

Asserting a niche

Jeco Plastic Products has been around for a half-century, but its appetite for niche opportunities that require precision molding and leverage smart manufacturing gives the company an ambitious start-up feel.

Craig Carson has no desire to make dog dishes. “Somebody else can do that in Hong Kong and I couldn’t care less.” the Jeco Plastic Products owner and CEO says.

In other words, let some other company crank out millions of plastic products in pursuit of high-volume markets; Jeco Plastic Products is focused on niche products that require exacting attention to tools, materials and processes.

That mindset has netted the small Plainfield company contracts in sectors that demand specialized and precise engineering, including aerospace, defense, pharmaceuticals, automotive and printing. Having owned the 50-year-old firm for the past 28 years, Carson proudly notes that Jeco has supplied parts to NASA for the International Space Station and to companies like Boeing Materials Group, SAFRAN and Lockheed Martin. Some 60% of the company’s business comes from international clients that put a high value on precision and are willing to trust small businesses with big jobs.

To win this business, Jeco’s two dozen employees design, engineer and produce plastic products through twin-sheet pressure forming and rotational molding of high-temperature thermoplastic composites (primarily for structural components, cabin interiors, cryogenic containers as well as other products for defense and aerospace purposes). None of these processes are unique to Jeco — some are used to create those dog dishes Carson eschews — but Jeco has carved a niche for itself by offering those processes in conjunction with high-precision engineering and large-product capabilities.

The production processes themselves are pretty basic: Each of them involves taking a base material, heating it to a high temperature and then molding or forming it to a specific shape.

Twin-sheet pressure forming is exactly what it sounds like, with two sheets of plastic being molded together to result in a final product. Rotational molding involves putting a thermoplastic medium (usually powdered plastic or cured resin) inside a mold, raising the mold temperature to an optimal melting point, and rotating that mold to distribute the medium evenly along the inside surface.

Once cooled and removed, the result is a hollow product that matches the mold’s specifications exactly. And while a lot of companies can offer these production capabilities, only Jeco offers results that combine these two complementary processes into custom composite parts as well. Products such as these are not only exacting but also massive. For example, its machines can produce single, hollow pieces that meet tight standards for tolerance even though their dimensions are measured in feet rather than inches.

Carson credits the pursuit of niche projects as a key component in his company’s growth (he’s increased his team by almost 25% in the past five years). “When you’re small you have to establish niches,” he says. “We have, for example, a very prominent position in the graphics arts industry. Ironically, this was not something I had any familiarity with 28 years ago, but we found a specialty that nobody else can do. We developed proprietary process techniques and stringent ISO 9001-2015 protocols which increase the productivity of standard printing equipment by 20-40%.”

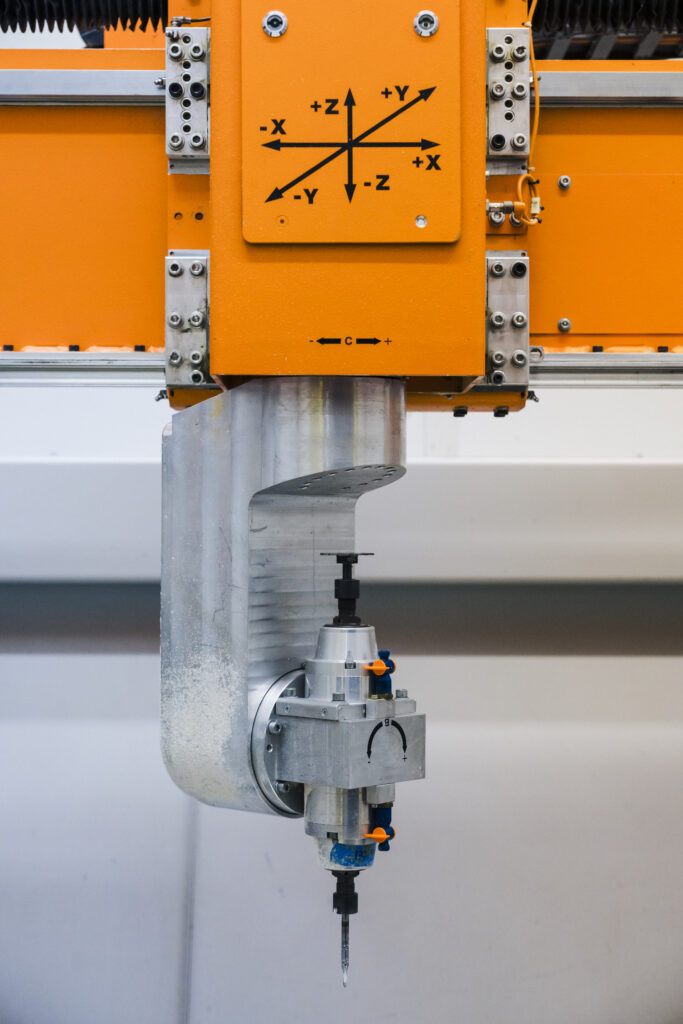

Jeco’s work leans heavily on smart manufacturing equipment and technology, with CNC trimming machines, 3D printers for prototyping and computer support factoring into its processes. In recent years, the company has invested in advanced thermoforming equipment, data analytics and other tools, all of which support its ability to land and deliver on technically demanding projects.

“It gave us the capabilities to move into things that are truly unique,” Carson says. “We’ve developed prototypes for hypersonic flight skins, for example. We have submitted White Papers in cooperation with Purdue for novel lightweight body armor. We design and manufacture products which are completely novel and are not commercially available. We have developed a process niche as well as a market niche, but we only pursue innovations which can be protected by large companies who are prepared to defend our jointly held Intellectual Property Rights.”

In its continuing pursuit of high-tolerance projects, in 2020 Jeco applied for and received a Manufacturing Readiness Grant (MRG) that upped its smart manufacturing game with equipment modifications and precision-measuring devices. This was critical support which enabled us to enter the aerospace markets.

Tapping resources to grow

Claiming a space as a company that could handle demanding projects, Jeco drew requests for projects with increasingly precise specifications. To equip itself for those jobs, the company tapped into grants and technical assistance found in Indiana.

As Jeco Plastic Products got more and more interest from customers that needed products with exacting specifications, the company recognized the need to invest in more sophisticated tools and equipment. For example, for projects in the aerospace industry, it needed to be able to confirm shapes and tolerances for complex curves, dual angles on corners and other tricky designs.

To this end, the company identified specific equipment it needed to purchase and alterations it needed to make to its current machines. It made investments out of its own resources but also applied its 2020 MRG funds to the project. The result was an improved ability to meet increasingly challenging customer requirements.

Jeco has also leveraged local technical assistance offerings – a couple of years later, a European customer asked them to obtain ISO 9001 compliance and then, shortly thereafter, the company asked for an even higher compliance, AS9100. Purdue’s Manufacturing Extension Partnership (MEP) advised Jeco through this process and helped it connect with funding through the Office of Local Defense Community Cooperation (OLDCC), which supported training for AS9100D internal auditing and for an onsite CNC machine.

With the resources supported by Purdue MEP, Jeco not only met the standards required by its current customers but also acquired a new multi-million-dollar international customer. Carson praises additional resources available from the Indiana Economic Development Corporation – which partners with Conexus Indiana on the MRG program – and the Export-Import Bank of the United States (EXIM).

While Jeco’s investments have allowed it to build a book of business overseas, the company also works close to home. One of the projects Carson has especially enjoyed in recent years involved another MRG recipient, Fishers-based Arctic Rx, which produces super-low-temperature containers for shipping pharmaceuticals.

Having found success in developing products that can tolerate ultracold (for example, for the International Space Station, Jeco made a part for a cryogenic container that had to maintain its shape and stability at -180° Celsius), Jeco was connected to Arctic Rx. Carson quickly found kindred spirits. “Right away, I thought, ‘These guys are like us,’” Carson says. “They’re committed.”

That faith was not given lightly. To meet Arctic Rx’s requirements, Jeco had to invest in upgrading equipment and capabilities. Carson believes the collaboration has been beneficial to both organizations, leading to opportunities to work on truly innovative and exciting projects and opening the door to ongoing growth. He sees a long future in the relationship. “They’ve never let me down, and I hope I’ve never let them down,” he says.

Jeco has complemented the material investments it has made to meet customers’ needs with ongoing training and education for its workforce, another area where MEP funds were particularly helpful. He notes that even long-time employees are working to learn new things and gain new expertise so they can continue to contribute to the company’s success.

Even a short conversation with Carson makes it clear that he measures success based on the satisfaction of his customers. For example, he proudly notes that Jeco won an innovation award from one of its larger international customers in a highly competitive contest in which the company’s divisions could each submit entries.

He also likes to tell the story of a project with a company in Germany. His direct contact was a highly reserved individual, Carson says, but when the project was completed after a challenging five years, his contact defrosted. “He said, ‘I knew we picked the right partner!” Carson says. “This is an unemotional man. And when you see that, you know it’s all worth it.”

Key Learnings: Focus, collaborate and make the most of Indiana

Nearly three decades of leading Jeco Plastic Products has taught Craig Carson to focus sharply, collaborate wisely and draw from all Indiana has to offer

Spend only a few minutes with Craig Carson and you recognize quicky that he’s an eternal learner and enthusiastic entrepreneur – and a big fan of the business landscape in Indiana. Here are a few lessons he’s learned over the years.

Find your niche and dive in. Jeco is an obvious example of finding a niche, but Carson would say the trick goes beyond simply discovering a gap you can fill. Instead, you should strive to become a leader in your area and create barriers to competition. One way Carson and Jeco have done this is by building on a lesson he learned years ago while visiting a German company. Seeing parts strewn around a factory floor, Carson assumed something was wrong with a machine. When he asked about the problem, he was told there was no problem; the company was building its own machine in order to ensure its unique value proposition. “How do you protect what you’ve got if you don’t actually change how you’re making it in some way?” his German colleague told him. “And I thought, ‘You know, that’s really true,’” Carson says.

Explore all Indiana has to offer. Carson is a cheerleader for the various grants, technical guidance, networking and more that Indiana has to offer. Options such as an MRG and Purdue MEP programs were difference makers when Jeco was looking to move into new markets.

Pull from Indiana’s synergy. In the various programs Indiana has to offer, Carson sees more than simply financial and technical supports. He sees a synergy between the public and private sectors that he believes is unique. “I’d like to be an example to others in the state of Indiana about how working together has really significant synergy,” he says. “And I’ll tell you something else: It’s not widely practiced in other places.”

Tap into Hoosier hospitality. Carson urges Indiana businesses to support each other, adding that he has found Hoosiers to be open to collaboration and simply helping out. For example, once, when he needed to find out how well a material could handle super-cold temperatures, he called up a nearby business that could help him test it. “I went there with my little sample in hand and asked if he could pour some liquid nitrogen in there,” Carson says. “It’s Indiana, so of course he goes, ‘Well, yeah, sure, come on in.’” After the pour, Carson subjected the piece to a “real engineering test” – hitting it with a ballpeen hammer – and found the product met the required standards.

Find a match for your mindset. In finding employees, collaborators, customers and suppliers, Carson urges finding people who share your values, objectives and mindset. “If you’re small, you better be a team,” he says. “That means you have to have a common interest, you have to have a common objective, you have to have common ethics.” As a veteran, Carson says he has found a lot of success in partnering with other vets, but he certainly believes it can be found in others. “There is a certain sense of unity you have to foster in a small company,” he says. “Colleagues need to know that loyalty is reciprocal. If you stand by me, I will never leave you behind.”

“I’d like to be an example to others in the state of Indiana about how working together has really significant synergy … And I’ll tell you something else: It’s not widely practiced in other places.”

Craig Carson

President, CEO at Jeco Plastic Products, LLC