Riverside Mfg. LLC earns $200,000 Manufacturing Readiness Grant to support $5.2m investment in next-gen technology, automation

Riverside Manufacturing

Key Stats

Overview

Riverside Mfg., LLC earns $200,000 Manufacturing Readiness Grant to support $5.2m investment in next-gen technology, automation

Manufacturing Readiness Grants (MRG) – provided by the Indiana Economic Development Corporation and administered by Conexus Indiana – incentivize, mitigate risk and accelerate the adoption of innovative manufacturing technology for small- to mid-sized manufacturers in Indiana. Riverside Mfg., LLC invested its $200,000 MRG in a next-generation $5.2m automation project to expand its product development line at the company’s Fort Wayne, Indiana plant.

Company History

Riverside Mfg., LLC (Riverside) was founded in 1947, and its headquarters and primary facilities are located in northeast Indiana.

Riverside grew from its initial roots as a CNC machine shop into a sprawling enterprise with a 150,000-sq.ft. headquarters and manufacturing buildings in Fort Wayne, while remaining heavily committed to Indiana. The facilities include plants for research and development, metal fabrication and injection molding, electronics assembly and electronic box build assembly. An additional electronics assembly plant is in Chesterfield, Michigan and North Stonington, Connecticut is home to a marine gauge assembly facility. Riverside specializes in several areas of custom product development, including printed circuit board (PCB) and electronics assembly, metal fabrication and instrumentation. At the time of its application for an MRG, Riverside had 300 employees, with 200 of those in Fort Wayne.

Riverside describes itself as having “the capabilities and expertise to manufacture any electrical product that comes our way,” with core capabilities in build-to-print manufacturing of harsh environment electronics and PCB assemblies.

The Project

‘Prosperity through diversity’ is the fundamental strategy for Riverside’s entire organization.

“Vertical integration is key to our strategy,” said Scott Maddox, Riverside’s Chief Product Officer who led the MRG project. “We started building our engineering staff to design different products for customers. Electrical design, mechanical design, embedded software, along with back-end web and phone app capabilities all now exist in concert. In addition to our design talent, we have the ability to provide injection & over-molded parts, cable and wire harnesses, electronic panel/box assembly and of course, printed circuit board assembly. That kind of diversity helps us weather a storm when different market segments are down. Right now, we’re starting to see the effect of onshoring. It’s been growing for the last few years, but lately it’s picking up a lot of steam.”

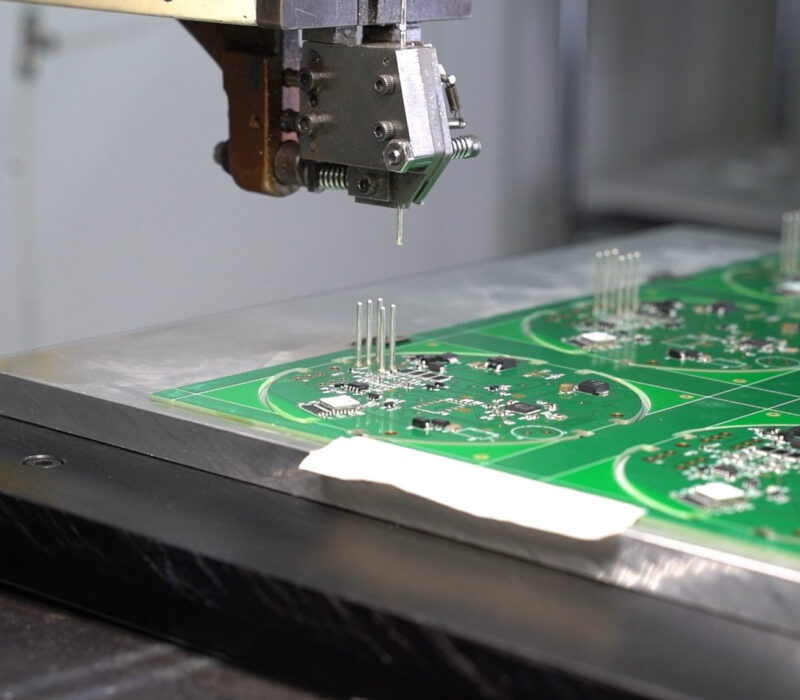

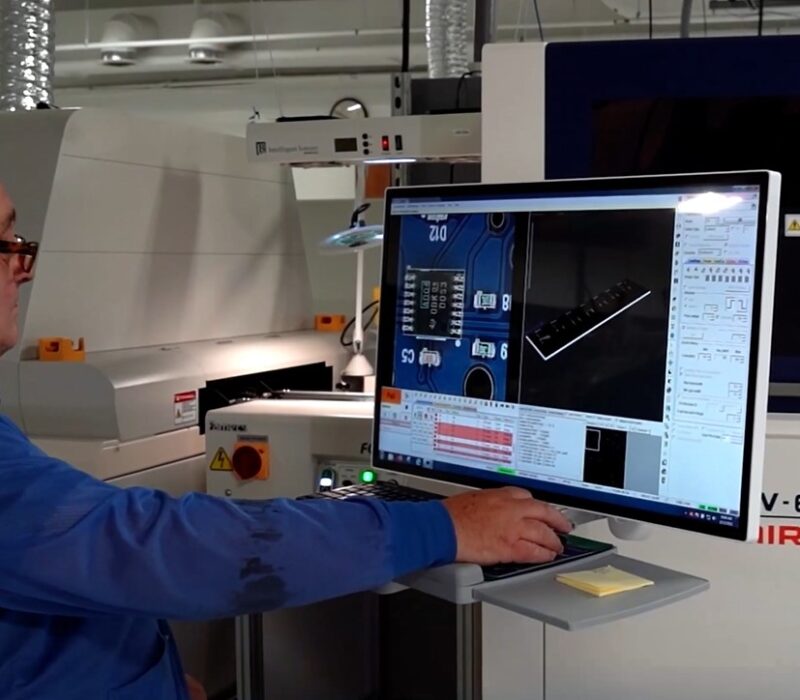

Needing to bring a higher degree of automation to their circuit board fabrication, Riverside’s plan was to expand from one production line to three more capable lines at its primary site in Fort Wayne. With higher speed and quality, Riverside’s throughput could theoretically leap from 100,000 components per hour (CPH) to over 300,000 CPH. The project was a massive undertaking with several aspects, all working together to transform Riverside’s manufacturing operations. It started with additional solder paste machines to increase the throughput of that stage of assembly. Very high speed “pick and place” machines were added to increase both speed and accuracy along with additional ovens. 3D Automated Optical Inspection (AOI) systems were added to identify any defects in the process. For circuit boards that still require leaded, “through-hole” parts to be used, a 2-stage selective soldering machine was added to automate what was historically a time consuming, manual operation. Finally, the addition of a selective conformal coating machine brought similar gains in speed and accuracy, improving the lifespan and reliability of electronic devices. “All of those things really turned us into a world-class circuit board producer,” Scott said.

Workforce Implications

Far from resulting in a smaller workforce, project implementation increased the Riverside employee count.

Riverside’s workforce has embraced the new technology. “No one was terminated because of the additions of this equipment,” Scott said. In fact, the company anticipated at least 40 new hires would be needed because of the growth enabled by this project. “It is actually a great example of how automation not only improves cost and quality, but facilitates growth so that it is a win for our employees as well.”

Shared Learnings

Leadership that supports new tools is an important aspect of growth and success, Scott believes.

Riverside’s ownership embraced this extensive project where many enterprises might choose a “piecemeal” approach instead. The comprehensive project included several pieces of hardware and software, described as “pretty audacious” by the Riverside team. “There is a lot of technology involved here. But we’re inherently building to a higher quality, and part of that is having more chances to detect issues early in the process.” He pointed back to the example of the AOI equipment where a piece of technology detects a potential problem before it can interfere with quality production.

For Riverside, a new product offering can be traced directly to the Manufacturing Readiness Grants program.

Ultimately, Scott pronounced Riverside very satisfied with how the entire project ran. “It was pretty painless,” he said. Painless enough, in fact, that the process has exposed another potential opportunity to provide greater services for its clients. “We have a customer who uses equipment we made for them, along with an app we made to control the equipment. It’s a Software-as-a-Service (SaaS) kind of program. Because the app makes the product more easily operated, it helps us sell more hardware,” he explained. Going forward, that SaaS offering is a key part of Riverside’s product diversification. The app’s convenience is an opportunity to monetize customer convenience by adding another valuable service. “Entering that line of work was directly enabled through the grant equipment,” he said. “The grant allowed us to build the module that we can sell. It’s a software skill set that may not have existed for us without the equipment that we gained with MRG help.”

Two lessons to remember: ‘You miss 100% of the shots you don’t take’ and ‘There is no magic bullet.’

Wayne Gretzky says his real comment was, “100% of the shots you don’t take, don’t go in.” But the popular version is close enough – and Scott agrees. He believes the best way to improve success is to stay informed and knowledgeable about the game. In manufacturing, that’s being aware of state-of-the-art trends and how they may impact your business. “We started intentionally searching for new technologies more than a decade ago,” Scott continued. “We’ve trained and committed ourselves to continuous education so we can see what’s coming down the pipeline that would really help Riverside. We know we’re good, but we also know we can be much better.”

Riverside’s resolve to actively know what’s possible is a distinct advantage. “As an example, some people don’t understand AI,” he said. “They think it can do more than it really can. It’s not going to build your product for you; it’s going to help you. But you still need to have smart people running the equipment and you still need your quality employees. There is no magic bullet.”