Case Studies

Tactile Engineering

Manufacturing Readiness Grant enables enhanced, automated production line for mass-production of a portable tactile graphic device

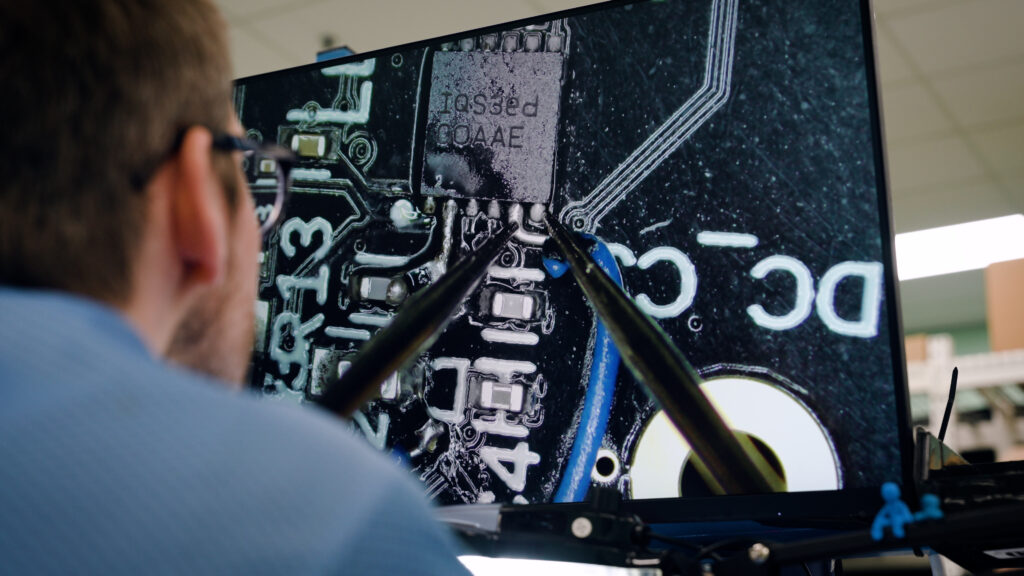

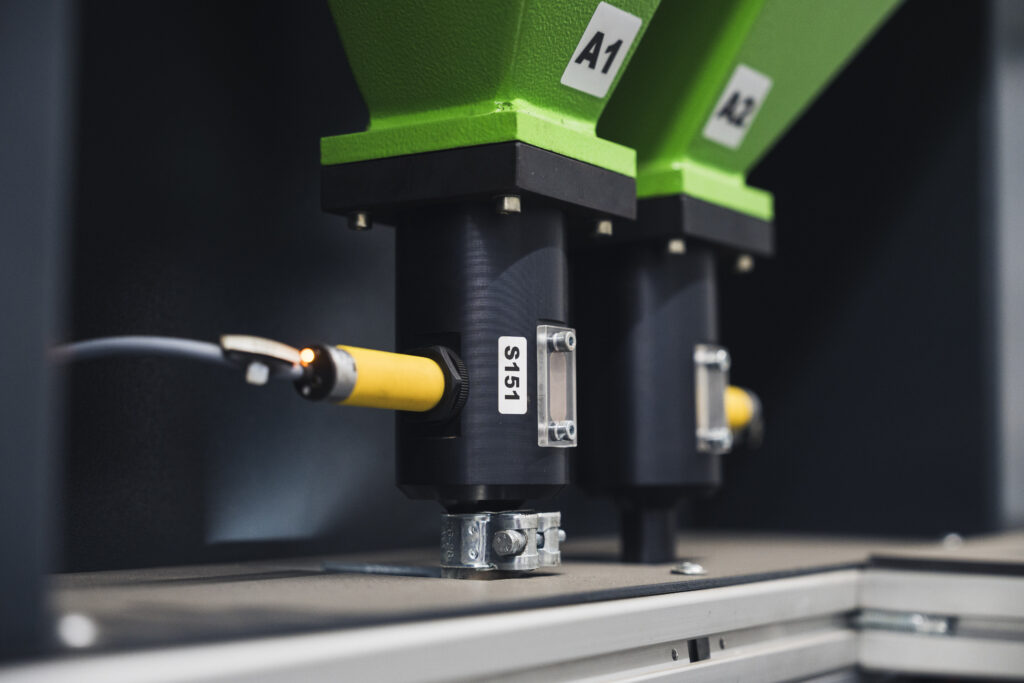

Tactile Engineering

Tactile Engineering staffers work at desks and electronics workstations, performing assembly and testing tasks. A robot arm moves a suction tube to position a tiny plastic dot in a tray with hundreds of holes. A rapidly spinning rod winds copper wire into a tight coil. Behind a green safety shield, a laser beam flashes over metal parts.

Monon Pax

Manufacturing Readiness Grant investment helps Indiana entrepreneur fill market gap with innovative co-packing solution

Industrial Pallet Corp.

Industrial Pallet Corp accelerates incremental technology upgrades with help of $150,000 Manufacturing Readiness Grant

ArcticRx by ChefsFridge Co.

ArcticRx by ChefsFridge Co. Leverages Indiana’s Advanced Manufacturing and Innovation Ecosystem to Move Rapidly from Prototype to Manufacturing Production

CosaWove Workwear

Indiana entrepreneur accelerates manufacturing expansion and community impact with a Manufacturing Readiness Grant

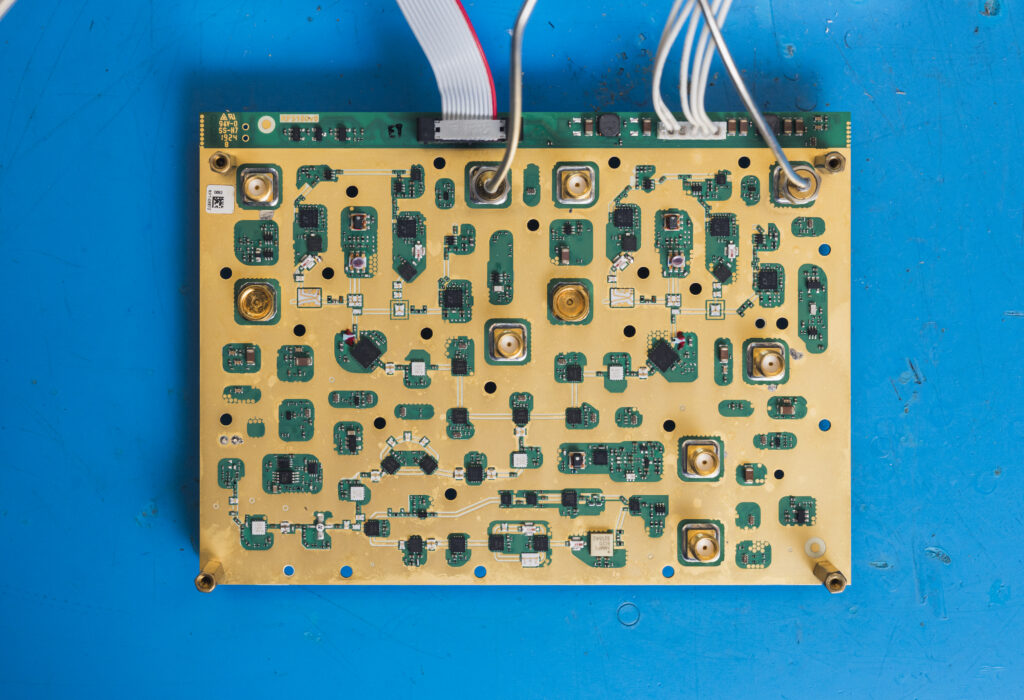

Copper Mountain Technologies

Hardtech manufacturer Copper Mountain Technologies expands product capabilities, enters new markets and makes a Moon landing with help from a Manufacturing Readiness Grant

WF Meyers

WF Meyers earns assist from $200,000 MRG to pursue premier manufacturing processes for the stone cutting industry

Metal Forming Industries

2 Manufacturing Readiness Grants, 2 Approved Projects – an Indiana Company Takes the Next Steps into Smart Technology and Automation

Holic Foods

Support from Manufacturing Readiness Grant Helps Entrepreneurial Holic Foods Ramp-up to National Presence with Automation