Innovative Designs’ two Manufacturing Readiness Grants introduce and expand automation at its Elkhart, Indiana plant

Innovative Designs

Key Stats

Overview

Innovative Designs’ 2 Manufacturing Readiness Grants introduce and expand automation at its Elkhart, Indiana plant

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana were available to incentivize, de-risk and accelerate the adoption of manufacturing technology for small- to mid-sized manufacturers in Indiana. Innovative Designs leveraged its 1st MRG to bring manufacturing automation to the company, and its 2nd to expand that automation for safer, more efficient operations.

Company History

New owner and President Jason W. Sullivan reimagined a decades-old manufacturing business, turning it into a robust, thriving enterprise.

For more than 30 years, Innovative Designs had been operating in Elkhart, Indiana without much change to the way it did business. The company built a solid reputation for producing quality sewn seating for automotive, RV, golf and marine industries, but like many of its contemporaries, was struggling in a work environment that had deteriorated over time. The manufacturing processes were physically demanding, and the methods of manually cutting and sewing fabrics using sharp instruments and heavy tools was inherently dangerous. The atmosphere, according to General Manager Chris Rosenberg, could best be described as a “sweatshop.” Employees had few benefits — no health insurance, sick leave or many other perks beyond mandated Social Security.

The “new” Innovative Designs became a more employee-centric firm through Jason and Chris’s vision. “We grew from 3 employees at the time of purchase to 15 by the time we obtained our 1st grant, and almost 30 by the time we installed the automation from the 2nd grant,” Chris explained. “It’s not that we’re just trying to be the biggest employer; we’re employing people for what we hope is not just for today.” The industrial sewing industry, he explained, has a low barrier to entry – Just buy a cheap sewing machine, some knives and start sewing. “We did things by hand,” he recalled. “It was antiquated and dangerous; there were injuries. Now, with the improvements we’ve made, we’re even onshoring jobs from China. It’s fun to bring back these jobs because our automation has made us competitive. It takes investment and we’re proud of that.”

The Project

Automation was key to growth for Innovative, not only from a production standpoint, but also for developing new markets.

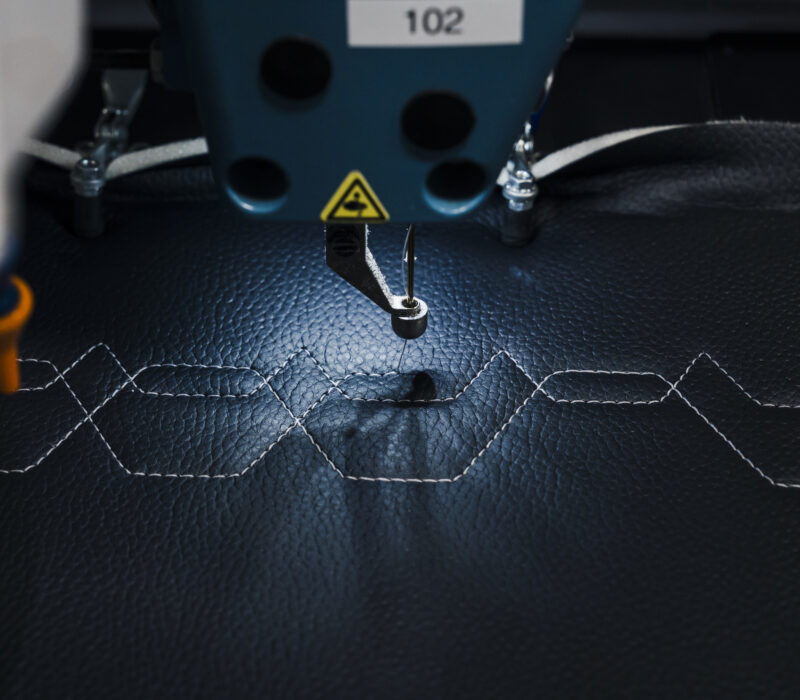

The first step on leadership’s automation roadmap was adding CNC ABM quilters, followed by a separate CNC cutting machine for wood and plastic materials. At the time, the company’s diamond quilt pattern required highly skilled hand sewers, making it difficult to keep up with and plan around anticipated production demands. Automation also meant the company would need more floor space to install machines, so leadership leased a larger building while on the search for the right equipment. But the path forward wasn’t clear at first – “We needed sewing robots,” Chris explained. “The only thing that keeps a robot from sewing is dexterity. I’m not saying we need to replace people,” he added. “I’m saying that when I need to get more production out, I need to be able to hit the dial and tell the machine to work a little bit faster. There are at least 5 times a day when I say, ‘We need another sewer.’ Well, good luck, because they’re like dinosaurs. You have to dig them out of the dirt now.”

Finding the right automation equipment and supplier – while making the return on investment work for the business – was no easy task. CNC quilting machines were an obvious solution but sourcing them proved difficult, as this technology was still in its infancy. Universities and some large companies in Germany were working to develop that technology, but finding U.S.-based manufacturers of established, proven equipment was hard to come by. Jonathan Lozada, in charge of sales and product design at Innovative, had been assigned to research the right equipment, and knew the company had always been reluctant to take on foreign-made equipment that isn’t widely used in the U.S. because it typically doesn’t have a strong reputation for quality and warranty service. Eventually, he discovered ABM International, a Texas-based company that showed real potential, and arranged to meet them at a Michigan trade show. “I was sold from that moment,” he recalled. “After we gathered all our information and considered the pros and cons, we ordered 2 ABM CNC quilter sewing machines. One could quilt virtually any product as large as 48”x32”, the other 63”x32”. Even having done our research, it was definitely scary, because it was our first step into automation.”

“I think Jason was a lot more confident in taking the risk when we learned about the MRG program, worked with Conexus and the IEDC and were awarded a grant.” With its enhanced capabilities, Innovative now competes successfully with much larger companies in the sewn goods space.

The availability of the Manufacturing Readiness Grant brought it all together.

Innovation requires investment, and Innovative Designs’ Grant Writer Kenady Sullivan helped solve that part of the equation when she learned of the Manufacturing Readiness Grant and informed the team. “This was a big leap for us,” Chris added. “It took a lot of convincing on Jonathan’s part. He got me on board, and I started nudging Jason and together we convinced him that the MRG would significantly contribute to our return on investment.” That application resulted in the company’s 1st MRG, totaling $100,000 to assist with the CNC quilter sewing machines.

Once installed, the 2 quilters made an enormous difference in the Innovative plant. Sewing by hand had previously limited production to straight lines. CNC quilting machines allow the operator to execute far more complicated patterns. “The machine automatically rotates the material and does all these intricate shapes that a human just can’t do,” Jonathan explained, “It keeps us competitive because companies with more financial resources will buy them, and now with the MRG, we can, too.” They are more reliable than traditional hand sewing and allow a single trained worker to supervise multiple operations at once. “The work of 4 people can be done by 1 person who doesn’t know how to sew but knows how to control the machine.” The 1st new hire with the installation of the CNC quilters was an engineer who programs the pattern with menus that make them easy to use and operate.

Those 2 quilters led to a 2nd MRG, more automation, and more growth.

With the success of the equipment purchased with the original grant, Innovative once again approached Conexus with an application for another project — this time for a for an almost $200,000 purchase, representing a capacity-building 3rd quilter, and new automation in the form of a CNC 3-Axis Wood and Plastic Cutting machine. It was the latter that provided the most compelling technology advancement to Innovated.

“When we were first introduced to the CNC quilters, we knew we would eventually want to automate our cutting processes,” Jonathan said. “Prior to that, we used a 15-foot table where we rolled out any vinyl for cutting to make the process not only more efficient, but much safer. Up until then, 2 or more workers would cut the fabric to the appropriate size, using what looked like a big electric butcher knife, and the process could be dangerous. This project made for a much safer workplace.” An additional benefit, he said, was that the cutting machine would automatically calculate the margin of error and material usage estimates, permitting more accurate quotes on intricate jobs. Increased quote accuracy would create the opportunity for new business development in the marine market.

Workforce Implications

The idea of new technology can be intimidating, but honest communication helps calm most fears.

“We still have little issues,” Chris admitted. “But in our case, and especially since COVID-19, we’ve been all about growing. We’re not trying to get rid of people. We’re trying to employ people. We work to get buy-in by the employees.” He pointed to one employee, a woman in the department who would be most involved with the new equipment. When Jonathan visited a Connecticut plant that had installed the CNC equipment Innovative was researching, she went with him to experience and evaluate the proposed technology. “From that experience, she has ownership in the project,” Chris said. “We paid for additional training for her, and she now has additional people working under her. She does a great job.”

It helps, too, that the workforce has continued to grow after the installation of the automation, from 15 before the project to 30 by the time the 2nd project was installed. The result of this approach? Most can see technology adoption as a growth opportunity as they take advantage of learning programs and rise to new employment opportunities. The bottom-line Chris drew was to remember that, while some employees may be concerned that automation will replace them, keeping them informed and involved can overcome most any fears they had.

Shared Learnings

Don’t be surprised when transformative technology comes with a learning curve.

Jonathan reminds employees and management that you must work with and learn with experience to truly evaluate how tech impacts you and the work you accomplish with it. “Remember, too,” he said, “you need to leverage technology to push productivity and to grow and compete.” As an example, he pointed to the first of the CNC quilters Innovative installed. “The integration process was frustrating,” he recalled. “We broke and trashed some parts in the process. But we persisted, learned and refined our techniques. We’re now the go-to in the market for this kind of technology.

Keep your company and your core values in sight.

Believing that Innovative’s reputation is an asset in the local community, Kenady participates with other employers and has mentored other local businesses in the benefits of the MRG program, steering some to apply. Recognizing that many companies don’t have funds to purchase the equipment, the company has made friendly customers out of would-be competitors. “We supply them with quilted inserts, and they cut the shapes and sew them together on the furniture they make,” Jason said. “I would say we have sewing companies that use us even though we compete in some cases. But they know we are professional, and we don’t steal their customers.”

Don’t allow yourself to be distracted or misdirected from your core purpose in business.

“What I really wanted to do was get a company that we don’t have to sell,” Jason said. “We’ve structured it through our family. I’m not trying to run this thing like a publicly traded company; we’ve set it up in a trust so it’s going to continue. Our employees know that. Chris knows that. What we’re trying to do is drive entrepreneurship. I’ve grown businesses in the past where we borrow to grow, and I saw an opportunity to do that. We still owe a little on the last piece of equipment that we bought, but other than that, it will all be paid off this year. We’re not allowing demand to force growth, to get us in a position where we need more than what we have. ”

Helping employees grow in their careers pays dividends for your business and your workforce.

When Jason reflects on the beginning of Innovative’s two successful MRG projects, he credits Jonathan for his help in shepherding both projects to success. “I had known Jonathan’s mother professionally for years and I worked with her at another company. I knew that manufacturing was in his blood, and he was coming out of college. Bringing him on board proved an advantage for us both,” Jason said. The job was fortuitous for Jonathan, as well. “I was graduating college and going into finance when the opportunity at Innovative came up,” he said. “Jason reached out to me through my mom, and it was a no brainer. It was a smaller company, so I thought I would be able to learn more and choose my path. Jason was always open to asking what I wanted to do at the company as it grew, and I’ve been able to try different things.” He embraced the opportunity to face new challenges every day. It was that structure that allowed Jonathan to become a driving force in advancing Innovative’s move into advanced manufacturing. “His hands-on approach and technical expertise were essential in getting the technology up and running,” Chris said. “He ensured the machines were integrated into our daily operations, making production faster, more precise and adaptable to custom clients’ needs.”

Jonathan was especially impactful in helping local small businesses produce custom parts that they previously had to source from out-of-state suppliers. The result lowered costs for those businesses and strengthened the local supply chain while keeping more work in Indiana. Another priority he took on was training team members on the new equipment, creating skill development and long-term growth opportunities within the company. “He knows how to collaborate, innovate and solve problems,” Jason said. “He pushed the company and the local manufacturing community forward and was a great example of how advanced manufacturing can evolve through both technology and people.”

Jonathan appreciates the opportunities he’s had at Innovative, too. “I’m the sales and product development manager, but my role at Innovative has always been wearing multiple hats.” He’s been able to expand his skills to include digital marketing, entrepreneurship, Lean Manufacturing and Lean Six Sigma abilities, among others. The company nominated him for the prestigious “Rising 30” award that recognizes Indiana’s emerging advanced manufacturing and logistics industries leaders. The award annually identifies 30 honorees under the age of 30, and Jonathan was a member of the 2025 Class. “I am thankful that I have been able to work at Innovative Designs and had the opportunity to grow in multiple directions that wouldn’t have been available at larger companies,” he said. “There is no doubt in my mind that I am a more well-rounded person, professional and team member.”

The company’s continued growth and success underscore how strategic investment in automation and workforce development can transform traditional manufacturing. Innovative Designs’ two Manufacturing Readiness Grants not only accelerated the company’s modernization but also helped strengthen Indiana’s reputation as a hub for advanced manufacturing innovation.