Manufacturing Readiness Grant investment helps Indiana entrepreneur fill market gap with innovative co-packing solution

Monon Pax

Case Study

Key Stats

Company History

Little Garden Foodies grew from a dietary consultation business to include Monon Pax, a complementary entity providing healthier hydration supplements and co-packing services.

Lindsey Rowan founded Little Garden Foodies (LGF) in 2017, after completing her MS degree in nutrition and integrated health at Maryland University. LGF fulfilled Lindsey’s goal of educating individuals and families in how to make changes in diet and health activities for a lasting impact on well-being and became the umbrella for her consulting business. Understanding that one size doesn’t fit all, she assists clients to find the approach that suits their time constraints, budget and personal taste. The business, she explained, reflects a quote attributed to Hippocrates: “Let food be thy medicine and medicine be thy food.”

As her business grew, so did Lindsey’s entrepreneurial aptitude. She learned more about water-soluble hydration supplements on the market – think “Crystal Light” and similar favored additives – and saw an opportunity for more varied and healthier versions of these supplements from plant-based vitamins and minerals. “People often don’t like to drink plain water,” said Lindsey. “After some research, it became apparent that we don’t know where many ingredients are coming from in existing hydration supplements, so it felt like I could take that on personally and develop a healthier, more transparent product.” In addition to providing products to enhance her clients’ wellness journey, the supplement could also expand her customer base. Unfortunately, there were barriers to market entry for companies like Little Garden Foodies and similarly-sized wellness businesses. Delivering supplements requires developing their recipes as powders and packaging them in stick packs. Existing co-packing services primarily focus on larger quantity runs, making it difficult to begin small batch production without significant capital investment in the packaging equipment.

And so was born Monon Pax, a small manufacturing company with the goal of using computer-automated equipment to package water-soluble health supplements for their own distribution, as well as for companies serving smaller markets and distributors. Monon Pax became the third leg of the triumvirate that includes Little Garden Foodies and Ryland Health, the company that concentrates on Lindsey’s nutrition products.

The Project

Through her research, Lindsey became convinced of her ability to maintain her consulting business while starting and managing the manufacturing endeavor of Monon Pax.

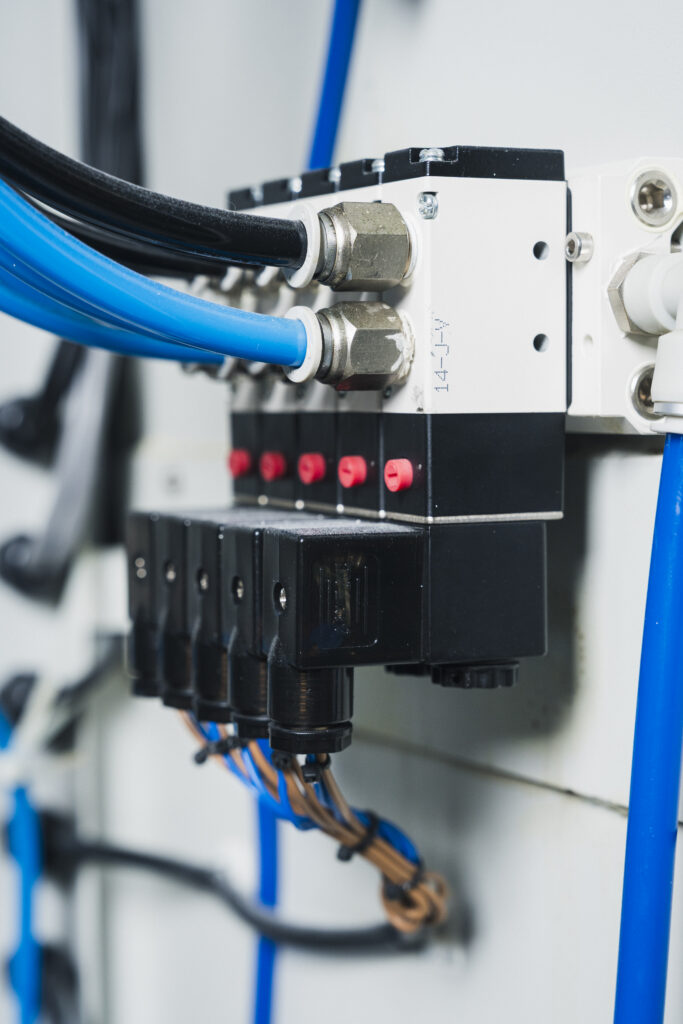

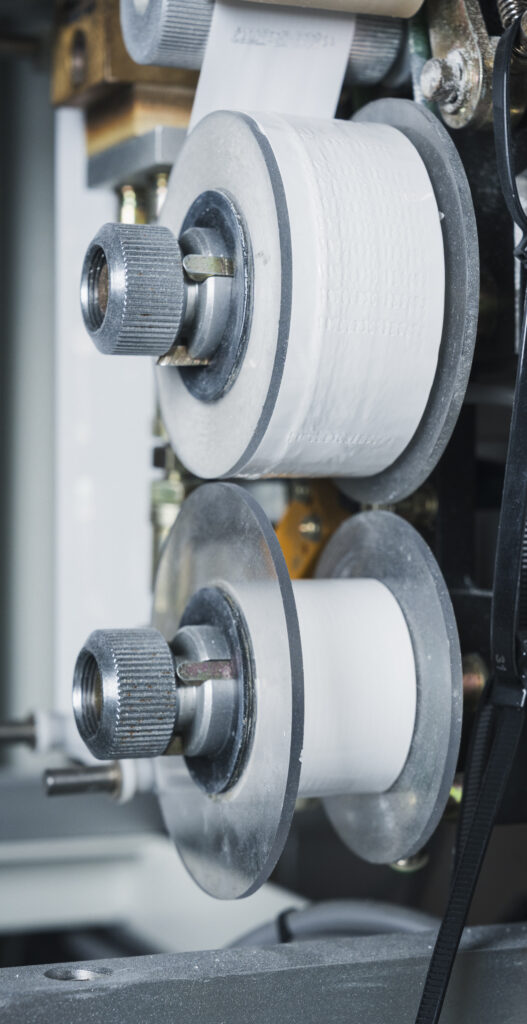

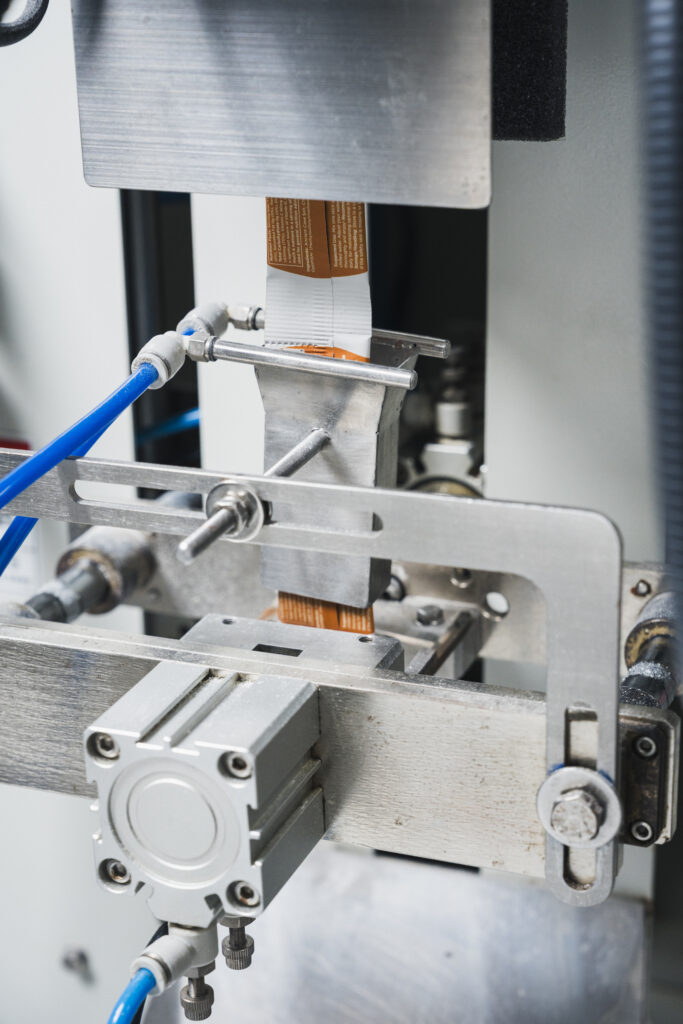

As she gained confidence in her business acumen, Lindsey began to research the ideal packaging machine for her use case, targeting something with a small footprint, positive reputation in industry and an ability package smaller quantities without overproducing – both for her own production goals and to serve as an effective co-packing partner for other small batch manufacturers looking to build their own brands. After visiting several trade shows and thorough market research, a specific machine stood out: the Model 55000 Quik-Stick Servo Auger Vertical Form Fill and Seal Machine. It was appropriately sized and capable of automatic operations, arriving on-site with a color touchscreen and Panasonic PLC machine controller for intuitive programming. These features offered a low barrier to entry for prospective manufacturers like Lindsey. Potential cobot support for automated material handling made this a sensible choice for her start-up manufacturing operation with room to grow.

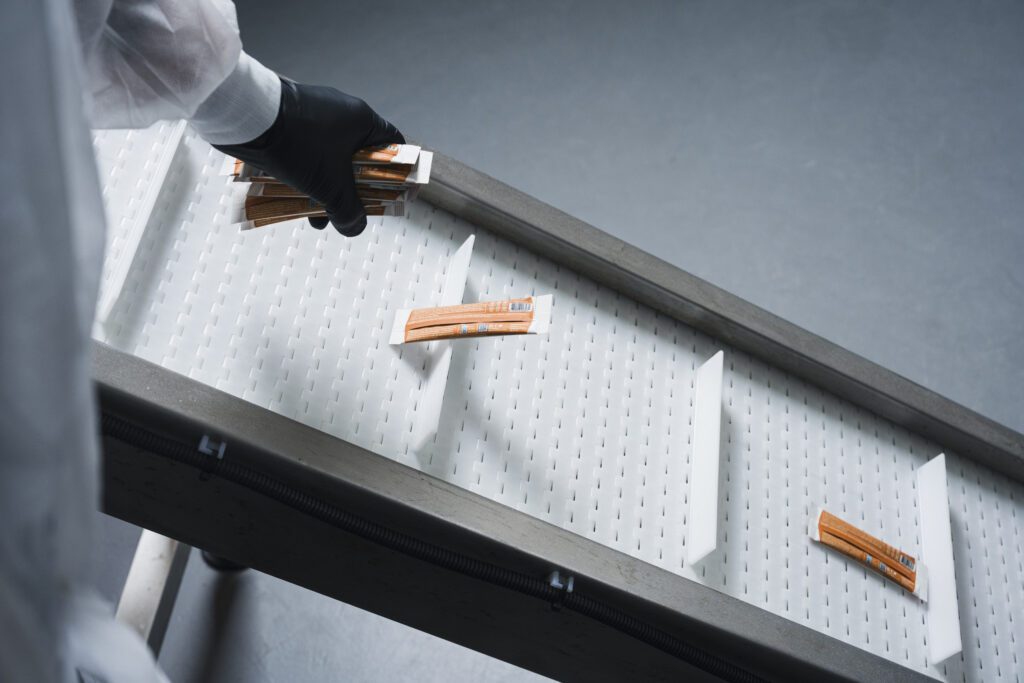

Since receiving the MRG and beginning operations, Monon Pax has helped several like-minded small businesses get a start in this space. “I feel like I’m helping those small businesses grow and at least get a footing. You have to have a product to be able to sell to any of these distributors or stores, even just small runs.” They offer turnkey service where Monon Pax receives bulk powders from a client that are measured, blended, packed and shipped from their Indianapolis location using the fill and seal machine. Their preferred business comes from packaging pre-mixed products where up to 15,000 stick packs can be created in an 8-hour shift.

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to incentivize, de-risk and accelerate the adoption of manufacturing technology for small- to mid-sized manufacturers in Indiana. Little Garden Foodies invested its $22,500 MRG award toward computer-automated equipment that enables the efficient manufacture of single-serve stick pack pouches for the wellness industry.

Key Learnings

Be prepared for start-up and commissioning when installing new equipment.

Start-up and commissioning are an important part of the installation process in the manufacturing world, Lindsey learned. “We ordered the machine. The dealer showed up on-site at our plant and started the commission process. Then you’re trained, you sign off, write the check and the equipment is commissioned. Only in our case,” she recalled, “there was an issue. The dealer came with the wrong materials to operate the machine, and he didn’t advise us in advance that we needed to have powder to run through it. We were ill-prepared for the start-up and commissioning of our machine.” Ultimately, the glitch was corrected and with a little extra time and collaboration with the manufacturer and dealer, the process was completed. But she advises any business installing new smart tech to make sure the installer is clear about exactly what requirements must be met before the installers arrive. “There was a lot of trial and error… since then, the manufacturer’s on-site training and instant availability over text has been very helpful in keeping our operation running.”

Machine learning really works, Monon Pax discovered.

The packing equipment’s machine learning and recipe memory capabilities have enabled Monon Pax to quickly standardize the consistency of new products. “You need to order enough material to test and calibrate,” Lindsey warned. “That can be a very big deal for small clients, because it’s costly to send that extra powder. But without the extra material, we can’t calibrate to ensure consistency.” Even with sophisticated packing equipment, it takes thorough documentation and trials to dial in product tolerances. Monon Pax uses the fill and seal machine’s built-in memory to digitally track and save production settings for each client’s product as the process is refined. “I’ve discovered the value of machine learning. One of our clients uses our co-packing services to make 5 different products. We noticed that their lemon lime flavor flowed really well through the machine, but the mango peach was a little bit sticker and needed more adjustments to hit the same tolerances. But with more runs, the machine automatically makes calibration changes. We have a client that’s reordered from us multiple times with a stick pack weight tolerance between 6.51 to 6.8 grams. On the first runs, it was hard to get there. But as we continue to run it, we’re very close. Out of a run of 20,000 sticks, we might have less than 100 that are not in compliance. The machine is getting much more efficient with increasing runs.”

Identify and keep moving towards the next steps for your business.

Realizing that success involves more than just the right machine, Lindsey follows her own advice in building future achievements on current improvements. “Always chose your partners carefully,” is at the top of her list. “Be sure they bring the promised expertise and add value to the enterprise.” She had a few bumps along the way in that arena, but it was early in the process and recovery didn’t interfere with her growth.

“Know what your clients expect and make sure you can deliver before you promise,” she adds. Lindsey took the time to thoroughly research the market and available equipment to meet her niche needs as a low-volume, high mix co-packer. “By the way,” she noted, I chose ‘Monon Pax’ as the business’s name to tie it recognizably to Indiana. Although we have clients around the country and, in a couple of instances, overseas, we are an Indiana manufacturer.” Monon Pax’s largest client today is in Tennessee, and she has received inquiries from Spain and Canada as well.

As for the future, “I still believe the stick pack market is huge and growing. That shelf at my local Kroger keeps expanding,” Lindsey said. “The next step for me is to find that location where I can get audited and certified for GMP (Good Manufacturing Practices), potentially growing to a location with clean room certifications to offer expanded co-packing services. I know that opens the door for more growth and success.”

“I feel like I’m helping those small businesses grow and at least get a footing.”

Lindsey Rowan

Founder of Monon Pax