Seeing an industry primed for take-off, Pierce Aerospace leveraged Indiana’s innovation ecosystem and government funds to take flight in Remote ID biz

Pierce Aerospace Inc

Product Development Case Study

Key Stats

Startup Journey

Pierce Aerospace co-founder found himself in the right place at the right time and – most important – with the right appetite and aptitudes to develop a product meeting new standards for all drones.

When drones flew onto the scene about a decade ago, most people couldn’t imagine how many eventually would take flight. The little whirligigs most of us saw initially seemed like either expensive toys or geeky niche tools.

Today, of course, drones are ubiquitous. In fact, the Federal Aviation Administration (FAA) reports that it has issued more than 800,000 individual drone registrations (and more than 1 million drone pilot certifications), and the Department of Defense (DOD) says that, on any given day, about 8,500 drones take to U.S. skies. It’s now common to see them performing a range of tasks for businesses, governments and individuals, from dusting crops, inspecting infrastructure, taking photos and measuring properties to delivering packages, amusing hobbyists and more.

Needless to say, with all of those birds in the air, the FAA needs to keep track of them. That’s where Pierce Aerospace comes in.

A little over a decade ago, when Aaron Pierce was working on a master’s degree in geographic information systems (GIS) at what was then IUPUI, the school was just starting a drone research center. The problem was, no one in the nascent program had an aviation background. But Pierce, who just happened to be focusing his studies on remote sensing technology, had spent time as a volunteer EMT and crew member on a Huey helicopter with a civilian nonprofit organization. Seeing a unique opportunity, Pierce leveraged his expertise and network to get input from the National Oceanic and Atmosphere Administration (NOAA) to help write the IU Indianapolis (formerly IUPUI) drone policy and operations manual.

“Taking my background on what professional flight operations looks like and networking with others, I saw this really booming industry that was just ready to take off, so I kind of pivoted from grad school and dove in,” Pierce said. “And I did so without having a business background and did lots of learning along the way, which I think is the best way for entrepreneurship.”

Pierce’s objective was to identify and solve really hard problems facing the drone industry. This initially led him to address the lack of data that plagued the FAA as it worked to create drone regulations, but he quickly recognized an even bigger challenge – and opportunity.

“As we dug deeper, we really got into the question of ‘Who is that and where are they?’ when it comes to drone operation,” Pierce said. “Those questions came down to a technology called Remote ID that we started pushing and pioneering back in 2017.”

At the same time Pierce was exploring these questions, the US government was developing regulations requiring drones to include Remote ID technology. The government released its regulations in 2020, to go into effect in 2021 (the effective date was later moved back to 2024).

Even before the federal standards were released, Pierce’s work caught the attention of the US Air Force Accelerator Powered by Techstars, which in 2018 tapped him to be an entrepreneur in residence for its accelerator program in Boston. A first-ever joint U.S. government and private-sector accelerator program, Pierce provided other startup founders guidance and support on developing commercially viable dual-purpose technologies.

As he was exploring the possibilities for his Remote ID technology in government and commercial sectors, Pierce turned to Small Business Innovation Research (SBIR) and Small Business Technology Transfer (STTR) programs for funding. “The SBIR program, especially for states like Indiana, is a fantastic place if you’re able to match a topic with the technology that you’re building with a customer,” he said. “I think it’s one of the best routes for small business to get traction with government customers and with building dual-use technology.”

Pierce said the SBIR and STTR process is instructive and beneficial, in part because the funding comes with government contracts on which recipients are graded and rated. “You have to perform,” Pierce said. “We were able to use the program to really get funding under us and really start building and growing as a company.”

Spending a career in the Department of Defense as a US Navy Civilian Engineer in Southern Indiana, Pierce Aerospace co-founder and chief technology officer Gary Bullock brings a view from “both sides of the desk” to the funding programs. “I think the thing that’s important to realize is that the SBIR and STTR programs are supporting cutting-edge research and technologies that are way too risky for private industry to fund,” he said. “It provides non-dilutive capital to small businesses that allows you to navigate the ‘Valley of Death’ … that gap between concept and deployment.”

The program offers additional benefits beyond that pain spot. For example, sole-source contracts that come with SBIR funding allow the government to continue using the technology developed in early stages without going through a competitive bidding process.

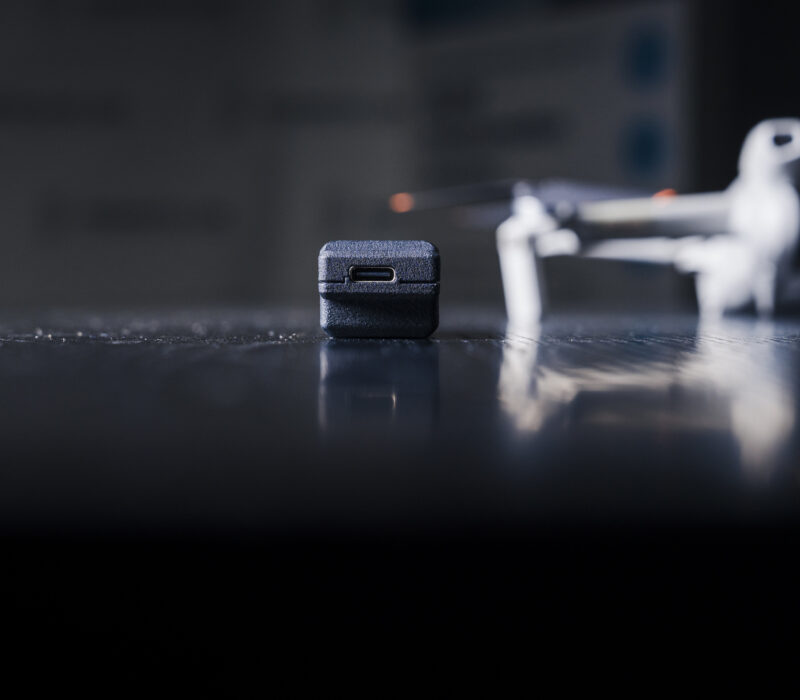

Pierce Aerospace, which also has received an Indiana Economic Development Corporation Innovation Voucher, officially unveiled its B1 Remote Beacon in late 2023. In 2024, it complemented that with the YR1 Remote ID Sensor, a sensor that passively monitors the airspace for Remote ID signals emitted from drones. The YR1 is in use at a variety of facilities and with municipalities, airports, government agencies, and a wide variety of airspace stakeholders. Its website includes a note to U.S. government contractors: “Pierce Aerospace has rapid sole-source procurement and contract vehicles in place. Please inquire.”

Hardtech Product Development Journey

Pierce Aerospace wasn’t satisfied with creating a product that would meet emerging federal standards for all drones. It wanted to offer the market leader and prove its reliability even before it hit the market.

When the US government announced its drone-recognition regulations, it required that any drone weighing more than 250 grams must carry Remote ID technology. Drones manufactured after December of 2022 must have that technology built into them; existing drones had to add an after-market identification technology. Enter Pierce Aerospace’s B1 Remote ID Beacon.

Early development of the B1 was done in-house, with Pierce Aerospace co-founder and engineer Michael Collins leading the way on circuit board design (shortly after graduating from Danville Community High School). Early iterations were created at the Indiana IoT Lab in Fishers, a space that Pierce said was beneficial not only because of the entrepreneurial atmosphere and support but because the noisy environment proved to be a good space for developing and testing a product that works on radio frequencies. “You can insert here your meme about, instead of being born in the darkness, we were born in the noise,” Pierce said.

As soon as possible, the team put the products into the hands of potential end users – for example, the products were tested in early stages with the US Army at Fort Sill in Oklahoma – so they could put them through the paces in difficult environments. Rose Hulman Ventures provided trusted and reliable manpower and ingenuity, helping the team get their product prepared for operational prototyping.

February 2023 proved to be a pivotal moment for Remote ID tech and Pierce Aerospace. At Super Bowl LVII in Glendale, Ariz., the government saw a prime opportunity for putting Remote ID tech through the paces. Pierce Aerospace was in the thick of things, with law enforcement drones relying on its product, as well as some of the commercial-media drones used for broadcasting the game.

“That was a game changer,” Pierce said. “In showing that the technology could work in that type of environment, we really used that to springboard into the commercial launch of the B1.”

The next challenge: Finding a contract manufacturer that could meet not just technical demands but also marketplace requirements. Because of the work with the government and military, the partner had to be a U.S. firm, and, just in case it proved necessary, Pierce wanted one with an ITAR (International Traffic in Arms) registration.

The National Defense Industrial Association proved especially helpful in connecting with manufacturers, Bullock noted, especially since Bullock was able to work through a familiar contact based in Indiana. “She’s a Hoosier,” he said. “That kind of helped, I think, to get over some of the initial dance, if you will.”

In choosing a contract manufacturer, the team put a high value on connecting with candidates, rather than simply assessing them from credentials and experience. They wanted to have relationships that ensured the manufacturer would be candid about its capabilities. “Don’t tell me you can do something then six months down the line go, ‘Well, now we can’t do that,’” Bullock said.

The team interviewed a number of potential contract manufacturers, seeking one that could deliver – at the desired quality and price point – a product that would perform at the high level demanded by professional and public safety and government operators. Creating such a dual-use product presented challenges, because some commercial-market manufacturers had no idea how to build something for the Department of Defense. “We opted for one that understood both worlds, understood us and wanted to have a good relationship,” Bullock said.

“We were pretty thorough in some of the question we’d ask,” Pierce said. “I think that helped to drive that relationship forward so that we went beyond just the relationship and saw that we could trust the process.”

With a contract manufacturer onboard to produce components, the Pierce Aerospace team did final assembly (and still does) at the Indiana IoT Lab, where it also puts the products through a quality-and-assurance process and test flights. “We are the only firm that actually test flies every single beacon before we send it out to our customers,” Pierce said.

The fully self-contained B1 units that bring drones and pilots into compliance with FAA rules are now in use in a wide range of government, commercial and private applications and settings. They allow users to track their drones and integrate them safely into other air traffic, coordinate with other drones and locate them in the case of a crash or other mishap. Pierce notes that, because many commercial drones are very expensive and tailored to specific uses, being able to recover a craft can be especially important. “There are a lot of cinematography drones out there with very expensive cameras on them, and they use our beacon to bring their drones into compliance but also as an insurance application,” Pierce said.

The marketplace has responded by adopting Pierce Aerospace products and seeking the company out as a supplier and partner. In May, the company signed a memorandum of understanding with MITRE National Range, and earlier this year it was part of a team of companies awarded a $50 million contract vehicle from the US Navy. Pierce Aerospace specifically was awarded a $10M Indefinite Delivery Indefinite Quantity (IDIQ) SBIR Phase III contract vehicle, a deal that will support further testing and deployment of the B1 beacon.

Key Learnings: From idea to market, there’s a lot to learn

For Pierce Aerospace, the product development process wasn’t simply a matter of getting from concept to market. It was an opportunity to develop and sharpen its product, learning at every step of the way.

It can be a long process from the recognition of a market gap to the market placement of a product that fills that gap. While some companies might see that process as a hurdle to be overcome on the way to success, the team at Pierce Aerospace seized it as an opportunity to gain knowledge and expertise, forge and sharpen relationships and improve their product. Following are some of the key lessons they learned along the way.

Leverage relationships. Aaron Pierce’s relationships from his past as an EMT on a helicopter came in handy for gathering information that fed the creation of the B1 beacon, and a connection Gary Bullock had from his days at Crane smoothed the way toward finding the right contract manufacturer. Others helped the process along in other ways.

Put the product into users’ hands. Pierce Aerospace put early prototypes into the hands of users and asked them to put the product through the paces. Not only did the team get great input for their product development, but they also had the chance to showcase the product’s capabilities and build relationships.

Find a collaborator, not just a vendor. A contract manufacturer is going to be intimately involved in your product and its success. Don’t choose someone simply based on technical qualifications. Choose a partner you can work with, that you can have a good rapport with and that is as excited about your product as you are.

Ask hard questions. When searching for a contract manufacturing partner, don’t hesitate to ask hard and direct questions to ensure they can truly handle the work and aren’t making promises beyond their capabilities. The deeper lesson: Good potential partners will ask equally hard questions, and you’ll learn from them.

Take advantage of Indiana funding sources, but also the knowledge base. One of the first lessons learned by the team might be that the company has benefited from being in Indiana. Not only does the state offer a number of incentives and supports for emerging businesses, but there is a deep well of expertise and a willingness to share it. “Take advantage of the manufacturing knowledge that exists really only in Indiana or the Midwest,” Pierce said. “I think Indiana definitely is a unique place to be able to do something like this.”

“Take advantage of the manufacturing knowledge that exists really only in Indiana or the Midwest. I think Indiana definitely is a unique place to be able to do something like this.”

Aaron Pierce

CEO and co-founder at Pierce Aerospace