Getting workers off to a ‘Strong Start’ pays off for contract manufacturer and its community

Background

If at any time since 1964, you wondered if the Knightstown company that for 60 years operated under the name HyFlex Corp. was forward-focused, you got a clear answer in the last few years. Not only did the company change its name in 2024 to NextGen Manufacturing, but it also embraced the slogan, “Leading the Future of Contract Manufacturing.”

And if that weren’t evidence enough, the 80-employee firm also upped its commitment to developing young talent in the Knightstown area. While it has had a long-running practice of welcoming students through its doors so they can get a taste of the working world, a couple of years ago NextGen Manufacturing formalized this practice under the banner “StrongStart,” confident that its program will pay rewards for the interns, the community and the company itself.

“The Strong Start program was built to help Knightstown in bettering the people who are physically here,” says Chief Commercial Officer Tim Riethmiller. “We truly do believe that helping the town helps better us.”

A contract manufacturer serving customers in a range of industries, from data centers to HVAC and from corrugated cardboard to ag, NextGen Manufacturing uses state-of-the-art equipment to take products from concept to finish or chip in at any stage along the way. While the bulk of the company’s workforce is in Knightstown, NextGen Manufacturing also has operations in Evansville and For Wayne.

Challenges and Solutions

While manufacturers across Indiana face a shortage of skilled workers, companies located in small towns and rural areas, like NextGen Manufacturing, feel the shortage more acutely, finding it difficult to attract workers from bigger towns and cities to even apply for jobs. Potential employees who do live nearby often find it difficult to get needed training without traveling to schools and training organizations in population centers. As a result, NextGen Manufacturing has found itself relying on headhunters and employment services to find skilled workers.

Even then, the company can find it challenging to find the right workers. As a contract manufacturer, it needs workers who are nimble and ready to take on a variety of assignments, and, like any employer, it wants people who fit into its culture and can hit the ground running.

In other words, it wants people who can get off to a “StrongStart.”

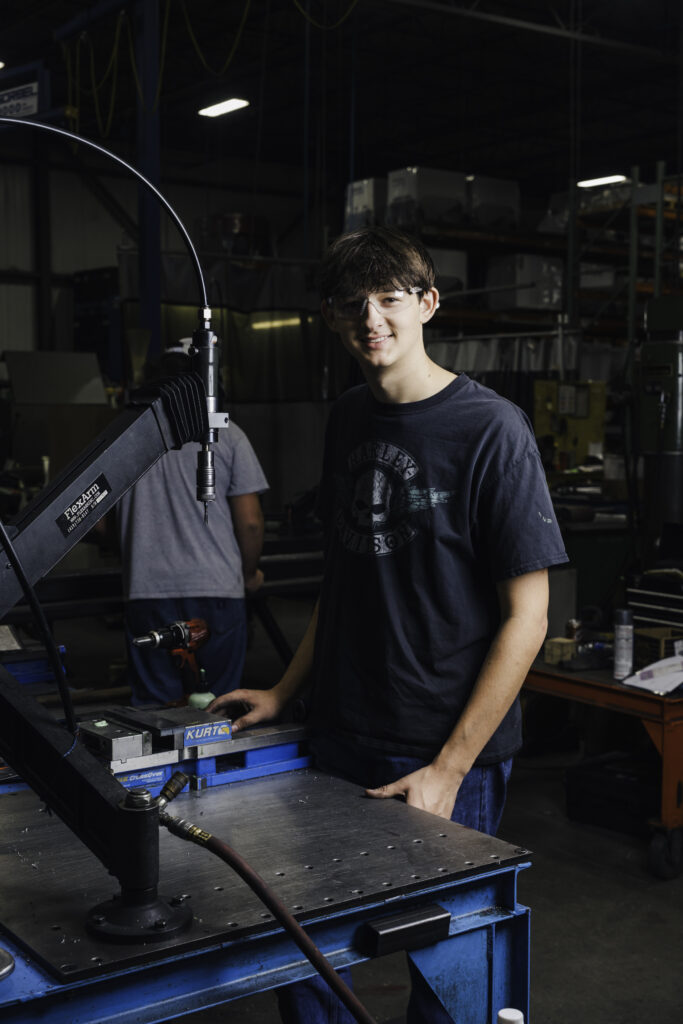

Growing from an established internship and training program, NextGen Manufacturing’s StrongStart strives to help participants prepare for jobs in the manufacturing industry. In addition to hands-on experience on the shop floor, the program gives participants classroom training and the soft skills needed to succeed in the workplace.

NextGen Manufacturing recruits for StrongStart in areas surrounding Indianapolis (including Anderson, Hancock County and Greenwood), reaching out to vocational programs and schools, offering field trips to the plant and inviting young people to tour the facility. Once they get prospects into the plant, they show off what it does and describe the StrongStart experience. Interested students can progress to interviews for spots in the program.

Once trainees are in the program, they get paid to experience the manufacturing world firsthand, gaining exposure to a variety of roles but also focusing on any areas they find particularly interesting. Regardless, they’re fully in the production mix, doing real work, learning on high-tech and high-production machines and contributing to multimillion-dollar projects.

Along the way, the StrongStart participants get structured mentoring, feedback and progress reports. Students can get college credit for their participation in the program, and they get the knowledge they need to qualify for certifications which, if they end up being hired by NextGen Manufacturing, the company will pay for.

With two spots available each semester, NextGen Manufacturing gets about 10 to 12 applicants a year.

Even people who don’t enroll in StrongStart can benefit. The company will provide a practice interview to anyone, regardless of where they’re looking for a manufacturing job. To Riethmiller, this is just further demonstration that the company is looking to the future and the greater good.

“I correlate it to planting a seed,” he says, adding NextGen Manufacturing doesn’t expect to hire every person who completes the program right away. Instead, the company knows that some people will get experience, learn how to operate equipment and technology, build soft skills, grasp what it takes to work in a manufacturing facility and then go work somewhere else. “And then,” Riethmiller says, “three to four years down the road, when they have even more experience and they become highly skilled, we then hopefully are able to reap the harvest and have them come back.”

That’s not to say the company always has to wait to reap what it sows. “We’ve been pretty blessed to have multiple people complete the program and be hired right away,” Riethmiller says.

Key Learnings and Outcomes

Two years ago, when NextGen Manufacturing decided to sharpen its workforce training program, it did more than simply give it a cool name and put some sharp graphics around it. It made sure that it had a structured program that would not just prepare workers for NextGen Manufacturing jobs but also equip them for manufacturing careers and strengthen its existing team. Following are some of the lessons the NextGen Manufacturing team learned along the way.

Market the program. Simply creating a program to bring in trainees isn’t enough, especially these days, when a lot of manufacturers are actively looking for workers and offering training. Marketing the program well is essential. That’s why NextGen Manufacturing rebranded its program and developed distinctive branding to support it. Not only did this help to attract attention, but it sent the message to prospects and their parents that this is a sophisticated program. They support this branding by sending representatives to schools, whether that means visiting vocational education classes during the normal school day or showing up at career fairs. They complement these efforts with social media and website promotion. The result of these efforts? They get better applicants who are already interested in manufacturing careers.

Have a plan. Don’t become a victim of your own success in attracting people to your facility. “There were days when we had back-to-back-to-back field trips coming in, and I will say some of us got caught off guard because we didn’t have the personnel in place to properly facilitate that number of people coming through in a single day,” Riethmiller says. Now his team develops a plan for spreading visits out and making sure they have enough people to manage them. That way, they have been able to ensure visitors have a great and safe experience and production isn’t slowed.

Check in with participants during the program. Don’t assume your job is done when a trainee arrives for the first day of work. Have regular check-ins to see how they’re doing. This has ensured that NextGen Manufacturing participants have a good experience and helps to build relationships that can last into the future.

Embrace the enthusiasm of current employees. While the focus of StrongStart is on attracting new workers, such programs also can have a positive effect on a company’s current workforce. “Our existing employees love it,” Riethmiller says. “Frankly, they just like when younger people come in, but they also love to be able to share their experiences.”

Don’t ignore existing workers. Speaking of existing workers, Riethmiller says NextGen Manufacturing has made a concerted effort to increase its already strong retention rate. One way it did that recently was by conducting an employee survey and truly paying attention to what the employees had to say. “Just one survey changed everything,” he says. Conducted anonymously by a third-party firm, the survey covered a wide range of topics, and NextGen Manufacturing made a point of addressing every issue raised by its employees, whether that meant hosting a cornhole tournament or sharing corporate financial results. “Unlike most companies, we did absolutely everything that they commented on,” he says. Employees see and appreciate the effort the company is making.

Make it about more than money. Companies talk a lot about the cost of recruiting new employees, but Riethmiller doesn’t even think about that when it comes to the StrongStart program. “I wouldn’t even say it’s a numbers game,” he says. “It’s a people game for us. We just genuinely believe that we can help.”

Live up to your community responsibilities. With 80 employees – and fewer than 70 working at the Knightstown plant – NextGen Manufacturing would be considered a small company in some places. But in its hometown, it’s a major employer, and the company takes that seriously. “I believe that we have a responsibility to this town, this county, this area to be a light,” Riethmiller says. “We own this building. We’re not going anywhere.”

“The Strong Start program was created to strengthen Knightstown’s local workforce. Investing in the people here directly supports our growth and the long-term success of our company.”

Tim Riethmiller

Chief Commercial Officer