Earlier this summer, as a part of our 100 Companies in 100 Days tour, we visited several advanced manufacturing companies in Central Indiana. The recurring theme that stuck out to us could be summed up in one word: growth.

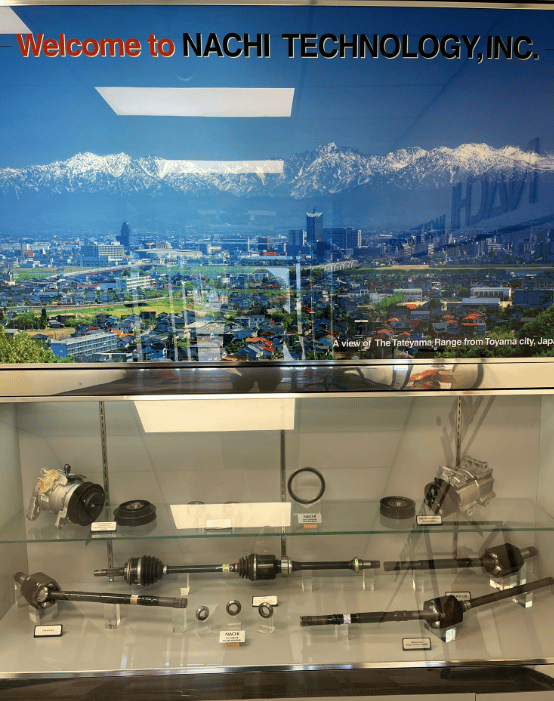

Greenwood’s Nachi Technology, a part of Japan-based Nachi-Fujikoshi, has enjoyed solid growth as a manufacturer of bearings for the automotive industry, and that growth is expected to continue as the firm begins production of a new part for hybrid vehicles. To accommodate this growth and more, the company is investigating options for increasing automation at its plant, which sits about 10 miles south of I-465 between US 31 and I-65.

But production growth isn’t the only reason Nachi’s leaders are pursuing automation. They also see it as a means to employee growth. Increased automation, they told us, will allow them to up-skill their workforce and create higher-paying jobs.

Fastener manufacturer AMPG shares Nachi’s views on the connection between automation and the growth of its people, but the firm describes the relationship a little differently. During a tour of the AMPG plant on Indianapolis’ northwest side, the firm’s team explained that they also pursue automation as a means for up-skilling their workforce and creating jobs, but they also see this process as a driver of innovation.

This is a view derived from experience. Having promoted several of its team members to leadership roles, AMPG has seen how those team members’ thousands of hours of training on the plant’s equipment helps them identify opportunities for innovation. A recipient of a Conexus Manufacturing Readiness Grants award, AMPG describes a virtuous cycle in which these factors combine to create higher-skilled jobs for current and prospective employees, which the company says is essential in a tight labor market.

Our visit to EnPower’s location on Indianapolis’ northeast side took us to a firm that is a relative newcomer to both the manufacturing world and Indiana. A maker of lithium-ion batteries, the company received its first patent in 2018, opened its research facility in Phoenix in 2019, and moved to Indy in 2022 to begin production this summer.

During the EnPower facility tour we saw how the firm has refitted an old manufacturing building with clean and dry rooms and other spaces and equipment needed for the three-day process of making a battery. As EnPower ramps up production, the firm is focused on growing its team to bring the facility to full capacity –and continue growing from there.

This post is a part of a series called 100 IN 100 –a look at Conexus Indiana’s staff visits to advanced manufacturing and logistics employers across the state. Conexus is visiting 100 companies in 100 days during the spring and summer of 2022.