Manufacturers seek to increase production flexibility and data security, reduce production costs

INDIANAPOLIS (Dec. 8, 2022) – Conexus Indiana today announced results of its annual Industry 4.0 technology adoption survey that, for the first time, shows a continuous and measurable trend in the technologies that are defining Indiana’s Factory of the Future.

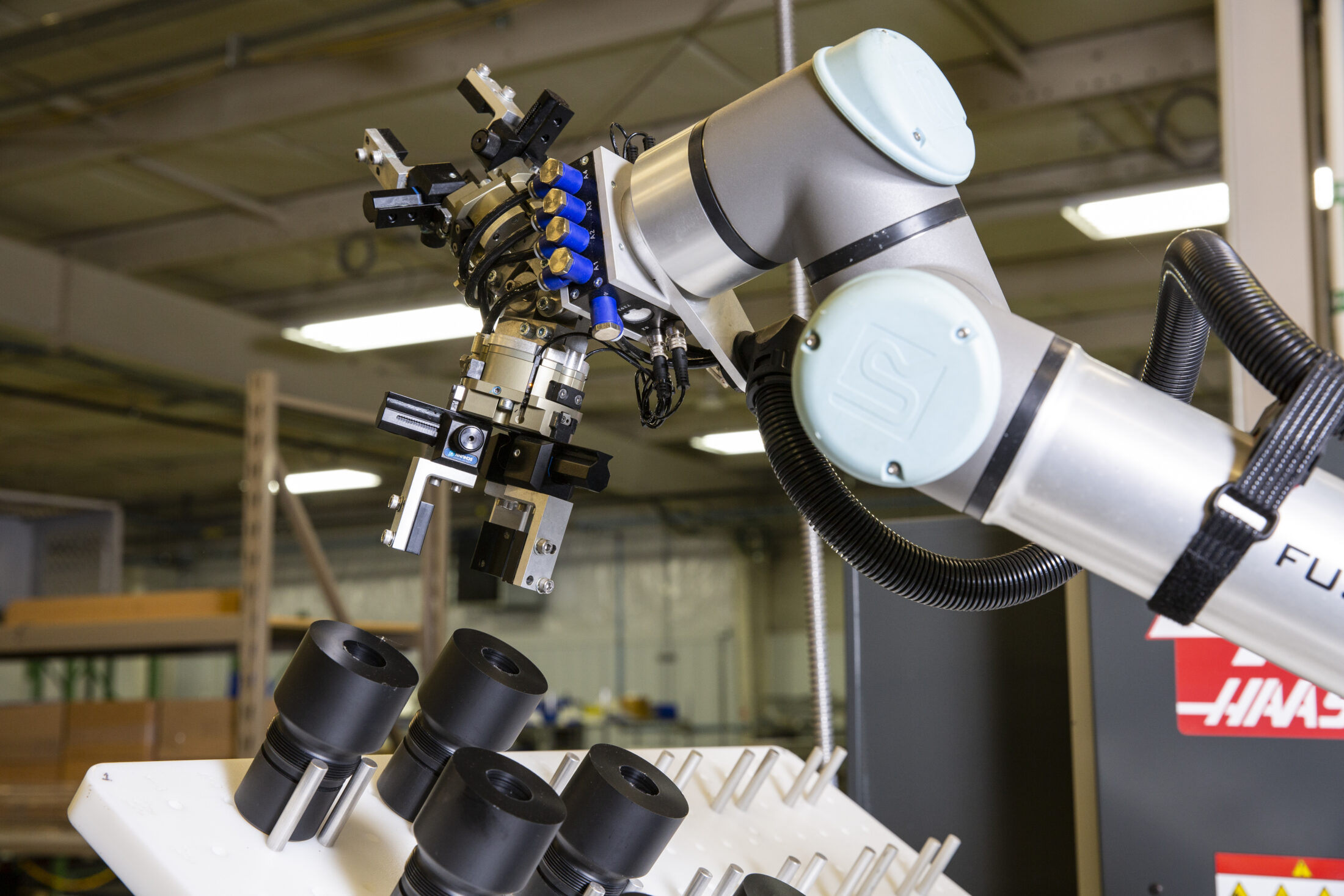

Conducted in collaboration with Indiana University Kelley School of Business Center for Excellence in Manufacturing, the 2022 study analyzed responses from nearly 200 Indiana manufacturers. Key findings show that cobots, cybersecurity, sensor technology and Internet of Things (IoT) are the top four technologies manufacturers expect to adopt in the next five years, each more highly anticipated than in years past. The percentage of manufacturers reporting plans to adopt cobots and cybersecurity in the next five years has doubled from 2020 to 2022, followed closely by a 25% increase in those planning to adopt sensor technology and a 68% increase in those planning to adopt IoT.

“We titled the 2022 report ‘A Glimpse into Indiana’s Factory of the Future,’ because with three years of data we can confidently paint a picture of what Industry 4.0 technologies Indiana’s advanced manufacturing companies are leaning toward for implementation in the coming years,” said Ryan Henderson, director of Innovation and Digital Transformation for Conexus Indiana. “There has been tremendous consistency year-over-year in the survey data; companies are clearly foreseeing what technology innovations are on the horizon.”

The mix of technologies identified by manufacturers for the Factory of the Future showcases a desire for production flexibility that can be achieved with cobots, cybersecurity systems to protect against cyber threats and data leaks and the use of sensor technologies and IoT to reduce production costs through key performance indicators like operating equipment effectiveness and predictive maintenance.

Overall Indiana manufacturers continue to prioritize Industry 4.0 technologies despite inflation, labor shortages and the supply chain disruptions of the last two years. Industry 4.0 technology implementations and pilot projects increased year-over-year: 58% of companies have now successfully implemented or piloted an Industry 4.0 technology, which is an 176% increase from 2020. Only 4% of companies reported no foreseeable adoption of these technologies, an 87% decrease from 2020.

As in the previous two studies, most manufacturers reported that technology adoption is not eliminating positions, but rather, is reducing monotonous and repetitive tasks and upskilling the workforce. Specifically, 61% of respondents said the adoption of new technologies will minimize repetitive human tasks; 52% said technology adoption will upskill the workforce; and just 12% said technology adoption would reduce payroll and eliminate positions.

“This year, cost reduction (efficiency) soared up the list of strategic business objectives for Industry 4.0 technology adoption likely due to inflation and the challenging macro-economic conditions,” said Mark Frohlich, associate professor of operations management and the Gregg and Sabine Sherrill Director of the Center for Excellence in Manufacturing at the Indiana University Kelley School of Business. “Indiana manufacturers see technology adoption as an effective strategy to cope with uncertainty, reduce costs, augment a tight labor supply and digitize operations.”

Additional findings from the report reinforce the need for companies to dedicate financial resources, develop a strategic roadmap and appoint personnel to achieve success in the fourth industrial revolution. While one in 2 companies reported having a dedicated Industry 4.0 team or leader, only 26% of respondents reported having a strategic roadmap.

“More Indiana manufacturers should take the time to develop a plan to catalyze momentum and meet their expectations of technology deployments in the next 5 years,” Henderson said, adding that “Conexus Indiana is committed to deploying the educational resources and programs that Indiana manufacturers need to succeed in the fourth industrial revolution.”

Read the full report on Conexus Indiana’s website here.

About Conexus Indiana

For more than a decade, Conexus Indiana, one of the Central Indiana Corporate Partnership (CICP) non-profit initiatives, has been positioning the Hoosier State as the best place for advanced manufacturing and logistics industries to innovate, invest, employ and succeed. By collaborating with industry, academic and public sector partners on a shared vision for an innovative, skilled workforce and stronger business climate, Conexus Indiana has helped to create opportunities for advanced manufacturing and logistics companies, prepare Hoosiers to succeed in the state’s largest industry sectors and maintain Indiana’s competitive advantage. For more information, go to www.conexusindiana.com.