Arcamed Leverages a Manufacturing Readiness Grant to Implement Two Cobots and the World’s Fastest Small Part Bending Cell

Arcamed, LLC

Case Study

Key Stats

Company History

Arcamed, a startup company committed to being a fast and reliable provider of case and tray systems and precision machined products to orthopedic OEMs, turned 10 years old in 2021.

Arcamed was established as a contract manufacturer of medical cases and trays, and expanded in 2018 to include precision machined instruments and orthopedic implants to provide physicians and surgeons with what they need to improve a patient’s quality of life. The product delivered to the surgeon is a “box” or “package” that contains the exact tools needed for a particular procedure, such as a hip, knee, spine or trauma procedure performed in hospitals or surgery centers around the world. Arcamed’s primary customers are small-to-medium size OEM’s (original equipment manufacturer) while also supporting the enterprise market.

A great deal of complexity lies within every package or box that is manufactured. The products must be traceable and are mainly custom to its contents driving thousands of possible Stock Keeping Units (SKUs). The cases are designed to be capable of shipment anywhere in the world, easily sterilized, and to the print specification of the OEM and the end-users the doctors. The rapidly growing Indianapolis-based company is thriving because of its core focus on product design and manufacturing process innovation to reduce both time-to-market and costs.

Another element fueling growth is the effect of COVID-19 on hospitals worldwide. Surgery centers were called into increasing use to respond to elective and non-COVID-related treatments, and Arcamed experienced an increased demand for its products. “It’s what I like to call ‘the COVID era,’” said the company’s President and CEO Jon Desalvo. “Our growth has been exponential. We’ve hired more than 42 people since COVID started. It really challenged us because it wasn’t the easiest of times to hire, and that led us to think about what we can do with technology to make things more efficiently and safely.”

The Project

Arcamed implements two cobots and a small part bending cell to increase manufacturing capacity and efficiency.

“We started our company using the best pieces of equipment we could buy on the used market as most start-up entrepreneurs do,” Jon said. “With the pandemic, we had to upgrade to smart technology, and the Manufacturing Readiness Grant helped provide us with the dollars we needed to accomplish that.” The answer was a Costa deburr machine: one of the world’s fastest single pass deburr machines. “It took us from 1 person on each shift or 24 hours of deburr work down to 2 and half hours for the same number of parts. Jon explained. “The parts we produce must be burr-free, smooth and without any hazard for our customer. They go into operating rooms, so we needed a technology that could accomplish that,” Jon mentioned.

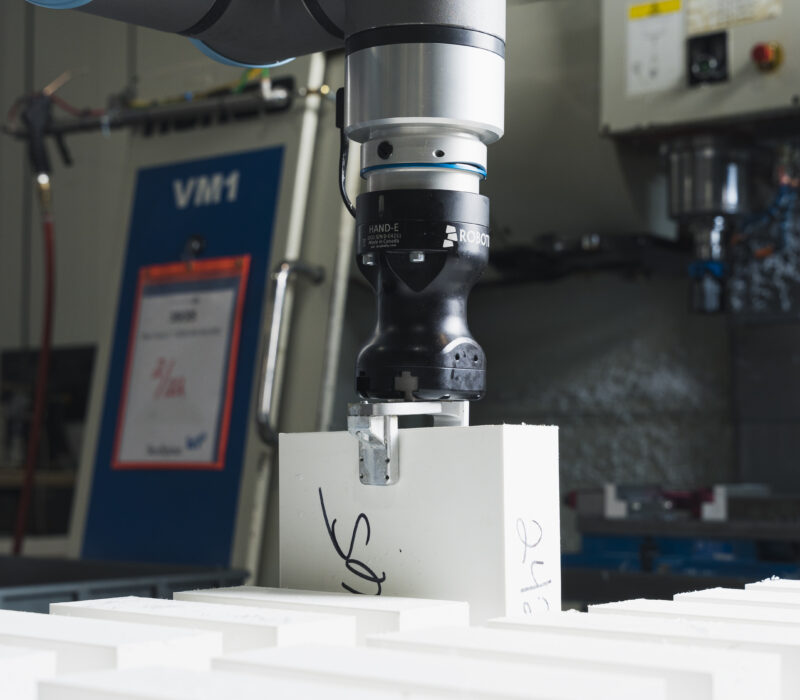

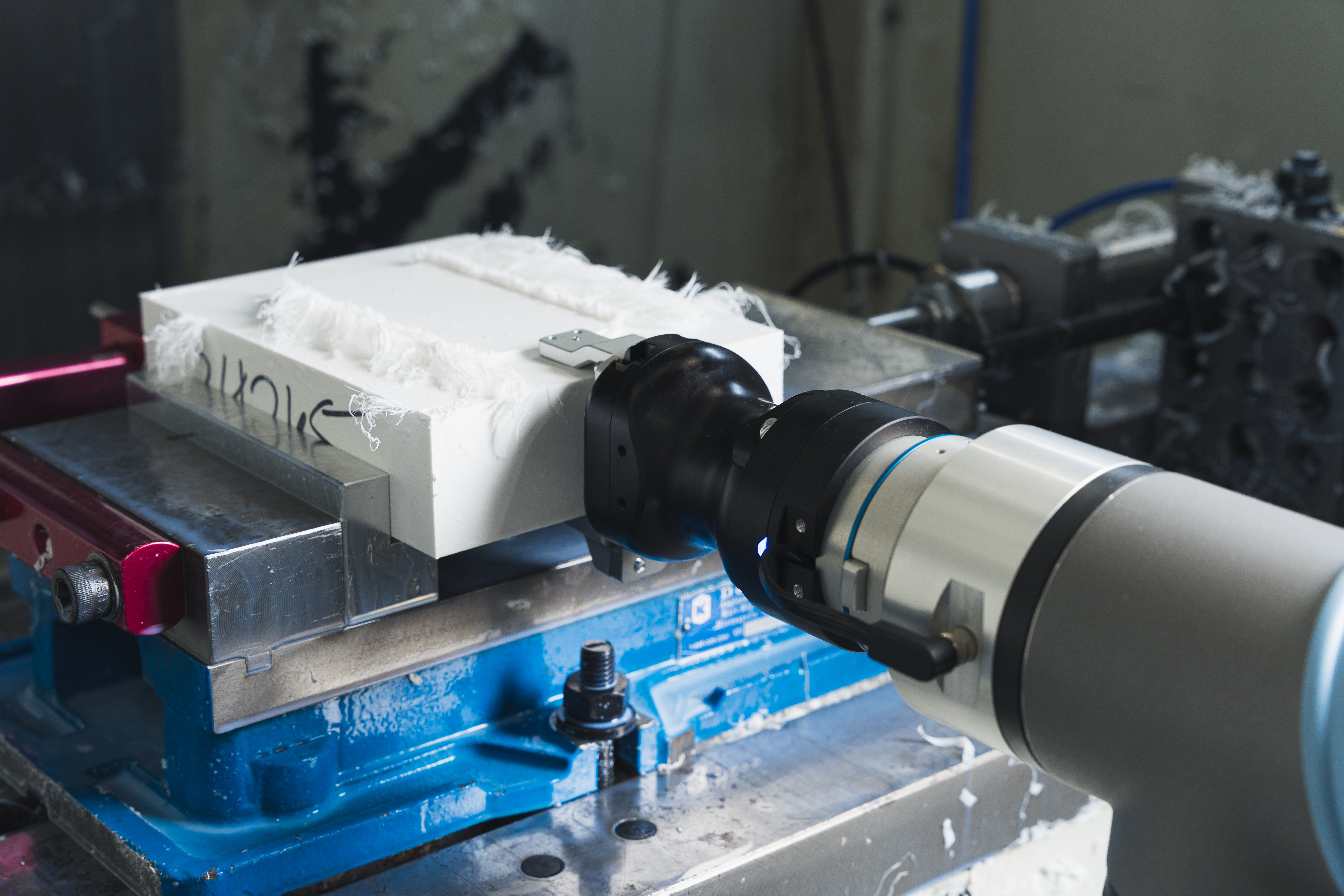

The project also included the implementation of two cobots for part handling, loading and unloading of machine parts as they are finished. “We went with two cobots rather than a robot because it would have meant additional guarding that took up space and complicated programming,” Jon added.

Jon revealed how cobots are incredibly user-friendly and hold an advantage over robots in that respect. But most importantly, the technology adoption project had to keep step with Arcamed’s relentless pursuit of product quality and safety.

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity. Responding to an extraordinary growth period, Arcamed invested in smart manufacturing technologies to nearly double capacity, increase efficiency and augment a tight labor supply.

Key Learnings

Arcamed’s new smart technology will better serve customers and improve the manufacturing environment for its workforce.

Like many CEOs, Jon recognizes that filling a growing workforce can be difficult. “There isn’t a real good feeder pool,” he said. “Some of what we think about is ‘how do we better deploy the people we have?” He continued, the most important question remains “how do we take the people we have and provide them with new skills and greater wages?” He believed the new technology would springboard Arcamed’s efforts to empower and train the company’s existing workforce.

Jon and the leadership team also wanted to be certain that the workforce understood the technology was not implemented to eliminate existing jobs. “I don’t want our employees to think for a minute that we are buying this technology to create a smaller workforce,” Jon said. He was also able to grow enthusiasm among his employees by showing how the cobots would improve daily duties and that the company was actively building training plans.

The Manufacturing Readiness Grants program spurred the creation of a strategic roadmap for Arcamed’s smart manufacturing journey.

“We also saw it [the grant] as a way to build a roadmap for future technology adoption that will help us grow and better serve our customers,” he said. “The grant has transformed the way we look at our business and how we plan for the future.” In fact, he said, we are now on that path, and the company has initiated its 4-year strategic plan with a technology adoption budget to make it happen.

He also urged others to set the time aside to make new projects successful. “The technology world is changing so quickly,” he said. “It was eye opening. As someone who’s been in manufacturing for a while, I wasn’t setting aside enough time to educate myself on new technology. I’ll tell you, the return on investment (ROI) is not long. From an ROI perspective, we went from equipment that needed a person to run it 24 hours a day, to a system that can run even when the lights are out. It can even run on the weekend when everyone is at home enjoying time with their families. And that’s game changing.”

“We also saw it [the grant] as a way to build a roadmap for future technology adoption that will help us grow and better serve our customers,” he said. “The grant has transformed the way we look at our business and how we plan for the future.”

Jon Desalvo

CEO at Arcamed, LLC