Catalyst PDG Takes Bold Steps to Increase Its Contract Manufacturing Capabilities with Support From a Manufacturing Readiness Grant

Catalyst PDG

Case Study

Key Stats

Company History

Catalyst PDG has earned a national reputation for its comprehensive product development services and nearly 25 years of industry experience.

Catalyst Product Development Group was founded in 1999 “by product designers, engineers and manufacturers to support product designers, engineers and manufacturers.” The company was envisioned as a complete product development service in a single location. This includes exploration, industrial design, engineering, prototyping, validation and low-volume production to translate clients’ ideas into market-ready and scalable products.

Today, Catalyst partners with corporates, innovators and creators to develop mind-to-market solutions, all while protecting each client’s intellectual property. Its 30 professionals share the company’s 28,000-square-foot facility on Indianapolis’s southwest side. The firm serves some of the most recognized and respected names in Indiana and the greater Midwest, as well as national and international players. To name a few: Eli Lilly, Cummins, Johnson & Johnson, Goodyear, Microsoft, Mesh Systems, P&G and Medtronic. There are dozens more.

“Innovative design concepts are critical, but they would never see the light of day if they can’t be cost-effectively manufactured at scale,” Catalyst’s Managing Executive Jason Andrews said, explaining the company’s engineering, design and manufacturing expertise that incorporates functionality and manufacturability into each product development project.

The Project

Increasing its contract manufacturing capabilities was on the radar at Catalyst, and supply chain disruptions caused by the COVID-19 pandemic demonstrated the need to accelerate that plan.

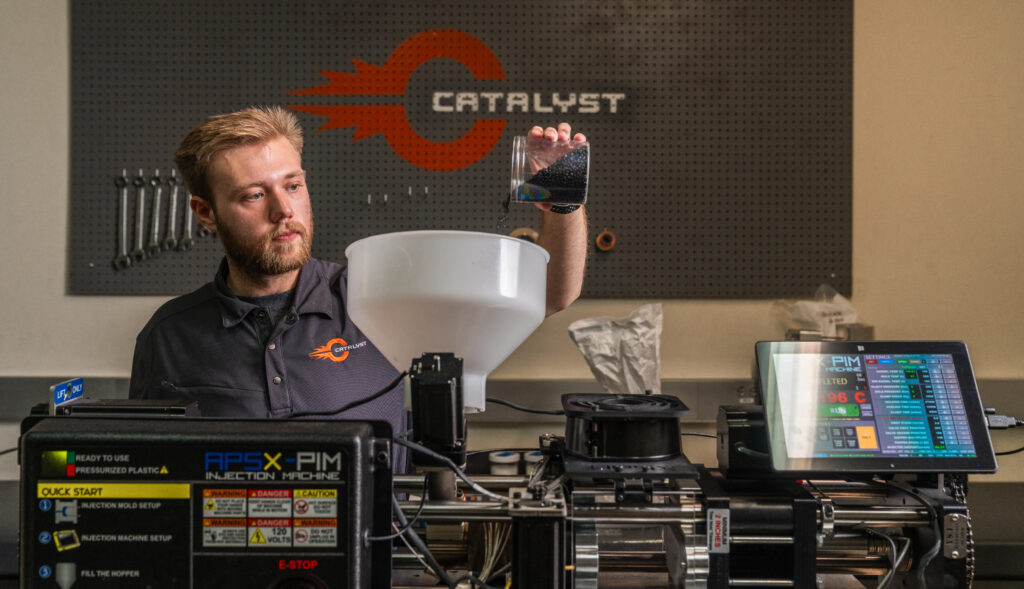

“From the beginning, we always thought the natural evolution of our business model would be toward contract manufacturing,” Jason said. “We’ve done some of that over the years. We have six molding presses and do a fair amount of injection molding. From time to time, there has been a need for more and more. But after the pandemic, clients came to realize how fragile their supply chains were.”

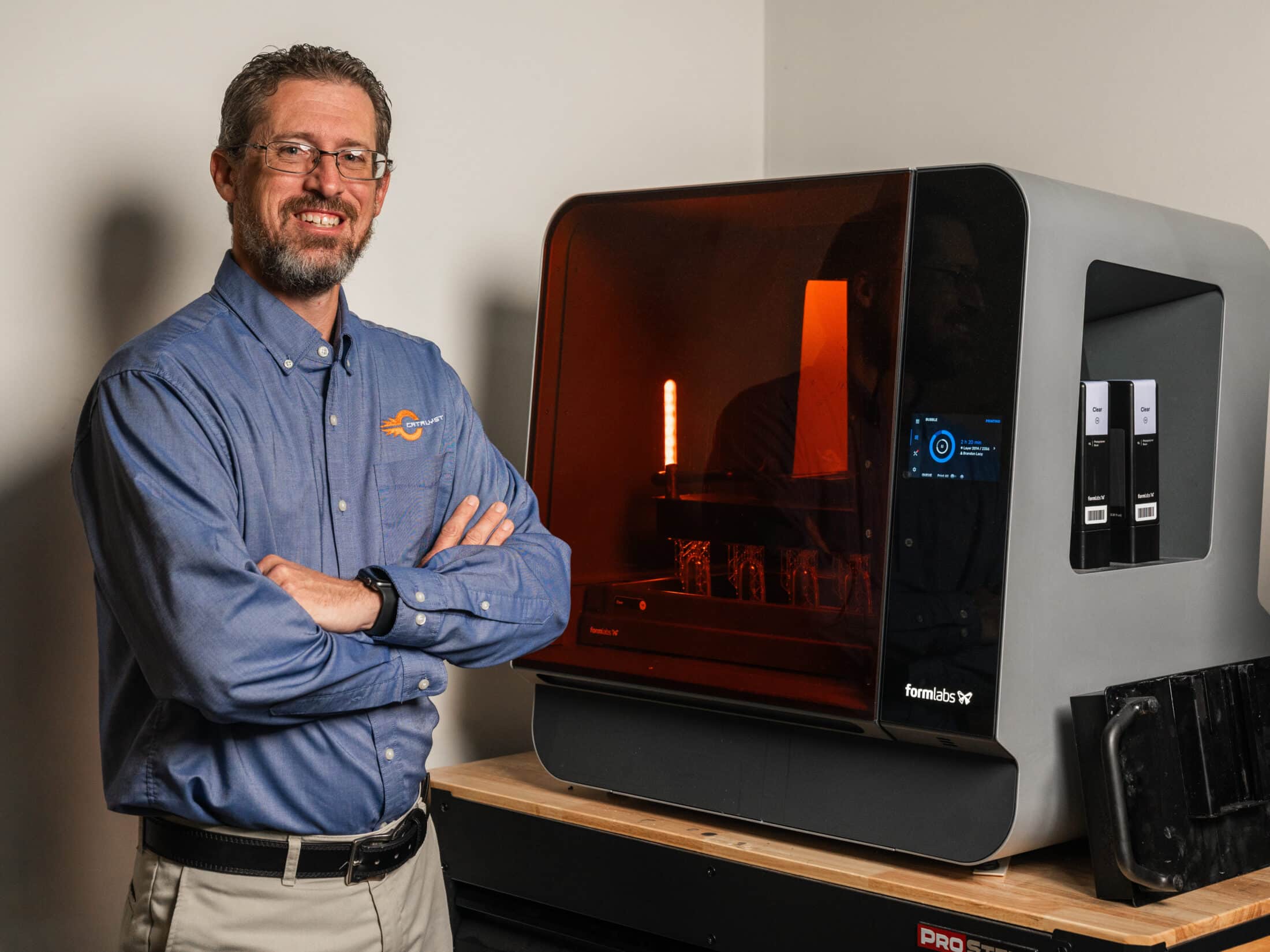

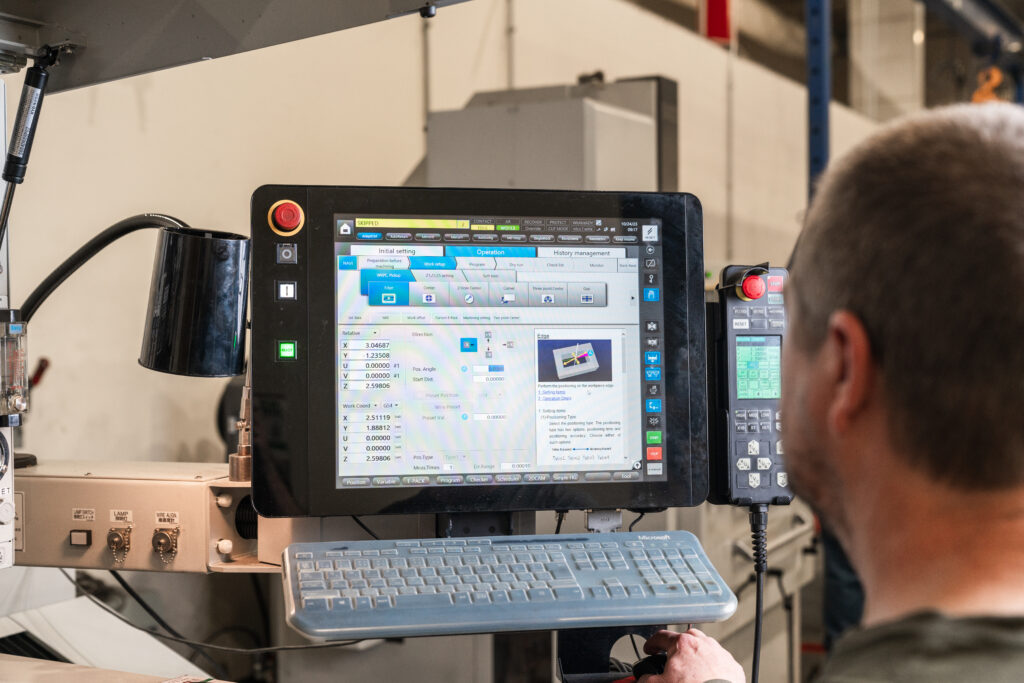

Reliance on overseas sourcing caused many of Catalyst PDG’s clients to ask if they had contract manufacturing capacity here in Indiana. In response to growing demand from their customers, Catalyst’s Director of Quality Control and Advanced Manufacturing Wayne Loynes led the company’s pursuit of ISO certification and an application for a Manufacturing Readiness Grant to help make it happen. “We were focusing not only on bringing innovations into the design and product development life cycle, but adding contract manufacturing services, too,” he said. “It’s starting to pay dividends.” Among the technology purchases to enable contract manufacturing were two next-generation production machines and a FormLabs 3D printer. The equipment was part of Catalyst’s plan to support client projects from prototype through to manufacturing. “Both long and short production runs are now possible, particularly for our medical device clients that were at the front of the line asking for that service,” said Wayne.

“Having these capabilities in-house is more than just offering our clients contract manufacturing services,” Jason explained. “It tightens our product iteration cycle on the design to prototype testing phase. In our facility, we have people who understand the manufacturing process working right next to our engineers and designers. Now we don’t have to send a design file out to another manufacturer to see what works and what doesn’t work with the design.”

In addition to shortening the product development life cycle, the increased in-house manufacturing capacity provided Catalyst with another distinct advantage. It keeps more of their services in-house and improves Catalyst’s ability to protect clients’ intellectual property. “That is a major focus of ours from start to finish,” Jason said.

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity and productivity. A $159,500 MRG helped Catalyst Product Development Group expand its contract manufacturing capabilities with the addition of a 3D printer and next-generation machines with integrated software.

Key Learnings

Technology adoption takes trial and error: Do your research and due diligence on new tech.

While the initial plans for the project were diligently considered and thoroughly researched, Catalyst leadership was not surprised to find a course correction would be necessary to successfully execute the project. “We went through a lot of trial and error, and we’re still learning today,” Jason said. “We didn’t have all the answers when we started. We had a good due diligence process on selecting the right technology and equipment, but we still had to learn as we went along.” Determining which 3D printer would provide the right capabilities is just one example. “There are many different printers for different materials and applications and it took time to identify what printer would suit our needs best.” Ultimately, the Catalyst team decided a FormLabs 3D printer served their clients needs best while still offering some flexibility. Catalyst’s Vice President of Product Development Andrew Mendenhall explained the impact of their decision to move forward with this specific 3D printer. “We have been able to design and build specialized tooling using the FormLabs printed and cured components to push the limits of what we could rapidly design and test in our advanced prototype and rapid tooling projects.”

Encourage different teams and departments to collaborate on technology adoption projects.

The collaborative nature of Catalyst’s business model simplified and enhanced the technology adoption process. “We try to make sure that our manufacturing and tooling teams are involved with the design reviews,” Jason explained. “At the end of the day, our organization has to bring together different disciplines and skills to go from design to prototype to manufacturing. Everyone knows what the goal is. Often companies with huge resources at their disposal can’t get product development and innovation done as quickly as we can. A lot of times customers are amazed by that,” Jason said.

The most important thing, Jason shared: “Build a robust project plan. New technology is a significant investment and takes time and resources to implement. If you’re adding something new, you need to have a plan that includes workforce development, training, integration and implementation.”

“From the beginning, we always thought the natural evolution of our business model would be toward contract manufacturing capability.”

Jason Andrews

Managing Executive at Catalyst PDG