2 Applications, 2 Projects, 2 Manufacturing Readiness Grants Take Creative Works to the Next Step in its Digital Manufacturing Journey

Creative Works

Case Study

Key Stats

Company History

Creative Works is a full-service partner for designing, fabricating, installing, and successfully running immersive amusement experiences.

Founded in 1997 by Jeff Schilling, Creative Works has combined a commitment to “EPIC Values” and a team-first, solution-focused culture to build a business that expects to grow to 100+ team members by the end of 2023. Since Jeff’s passing, his three co-owners have guided the company forward, creating immersive attractions for entertainment venues around the world. Today the three co-owners (Jeff’s wife, Kimberly Schilling, and company President Armando Lanuti and his wife, Amy Lanuti) have expanded from the original laser tag installations into 3-dimensional products, glow-in-the-dark mini golf, e-sports, escape rooms, virtual- and augmented-reality and custom theming. In fact, when they recently moved from their original Mooresville location into a new 50,000-square-foot headquarters and factory space on Indianapolis’ near southside, they called the building the “Theme Factory.” Visitors are welcomed to tour behind the scenes and meet the people who make the magic happen—what Creative Works calls “The Wow Effect.”

“The Wow Effect” reflects not only the products they create but a vision that describes the future of the company and the plans to achieve those goals. In addition to ensuring financial growth and profitability, giving back to the community is an essential part of the business formula. In 2021, The Giving Foundation was created to honor Jeff’s community values and spirit of giving. Since then, the foundation has supported the company’s creation of themed rooms in a children’s hospital, partnerships with Big Brothers Big Sisters of America and other ways to leverage the unique skills and talents of the Creative Works team for the betterment of the community.

The Project

Both technology adoption projects at Creative Works were executed to increase productivity and product quality.

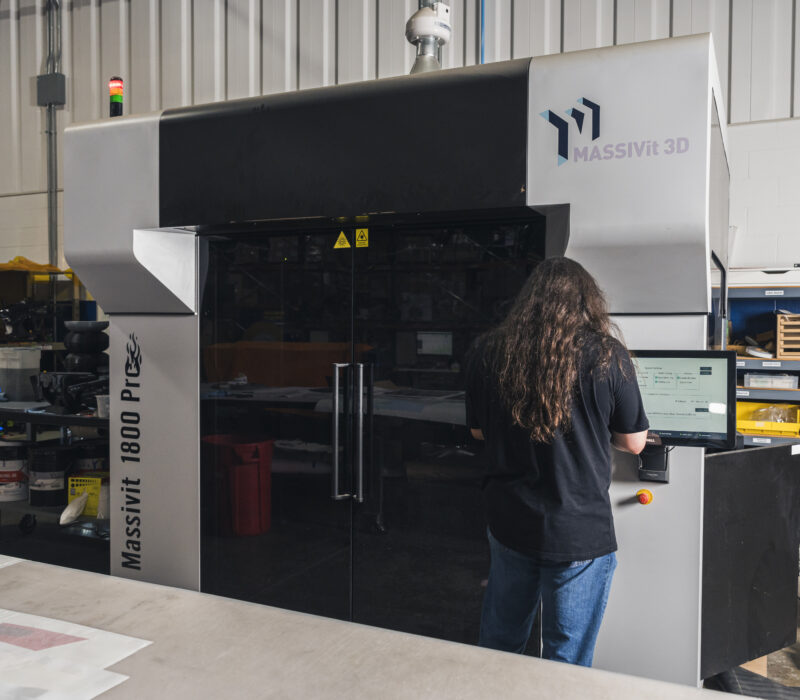

The first MRG project—the next-generation CNC machine—does the work of three earlier CNC machines, allowing the production of more complex props and attractions, including fully automated tool changes. The second project—a new large-format industrial 3D printer—moves the production process beyond subtractive manufacturing into additive manufacturing and reduces the company’s dependency on outsourcing.

Mark McLaughlin, vice president of operations, and Zack Tetrault, production manager, explained how the two new equipment purchases that included software upgrades, were major steps forward in smart technology and digital manufacturing. With the new equipment, Mark said, the company is finding “new ways to explore the boundaries of artistry and engineering.” The next-generation CNC machine’s tool changer is one of the biggest advantages in production, Zack said. With 13 different part options, it allows engineers to make more complicated props and doesn’t require the operator to manually pause to change parts during a run. A programmer skilled in SolidWorks software was added to the workforce to increase the accuracy of the design files and the speed from prototype to production.

The large-format industrial 3D printer purchased with the help of a second MRG improved the Creative Works process in the development of new tooling for molds, increasing manufacturing flexibility for custom jobs. Reduced outsourcing was now possible with these added additive capabilities. The ability to produce challenging organic shapes is building a competitive advantage and now has become an in-house strength.

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity and productivity. Creative Works applied for 2 separate MRGs—one to support an investment in a next-generation CNC machine and a second to help deploy a large-format industrial 3D printer. Both were successful, providing the company with $75,000 and $83,000 for each project in supporting funds.

Key Learnings

The technology adoption projects show an immediate ROI by way of new business opportunities.

The new equipment has resulted in company growth and Creative Works recently moved into a new, larger Indianapolis facility. “We’ve discovered constant opportunities to stretch and leverage the new technologies into larger projects and customers,” Mark said. “The CNC machine project was relatively straightforward, but we saw immediate returns on that investment. Implementing the new 3D printer was more complex and involved determining the right materials, design possibilities and workforce training. After successfully applying for the first grant and completing that project, Creative Works applied for another grant that was both independent of and a natural step in terms of technology adoption from the earlier project.

The combination of a new facility, new software and the new smart technology spurred both growth, skills, and awards in Creative Works’ workforce.

In 2021, the company had about 60 employees when it applied for its first MRG and had grown to 85 by the time the second project was installed and operational. Its 3-year vision statement cites more than 100 employees on staff in early 2023, and recognition in the Inc. “5000 Fastest Growing Companies in America,” and as the “Best Place to Work in Indiana.”

“We’ve been in this massive growth period for probably the last two or three years,” Mark said. “With our new facility, new software, new employees and our new advanced technology, we’ve been able to bring in some big projects with major names in the entertainment space.” All of that reflects the culture at Creative Works—a culture that was designed to nurture team members with a focus on work that is “Fun, Creative and Challenging.”

“We definitely try to leave people better off than we found them,” Mark said. “We don’t just have a business to make money. We have a business that impacts the community, where we all live and play.” Mark’s own story took him from an entry-level equipment installer to his current position as vice president of operations. “The company saw that I wanted to do more. I was also hungry and curious,” he recalls. “I worked my way up from equipment installer through project management and product development and operations.” He describes it as a “bottom-up” style of management that encourages employees to perform in multiple roles and be trained in different areas of the business. “On any given day, you could do something totally different and that’s what I really love about it here at Creative Works.”

“The two new equipment purchases were major steps forward in smart technology and digital manufacturing. The company is [now] finding new ways to explore the boundaries of artistry and engineering.”

Mark McLaughlin

Vice President of Operations at Creative Works