Social Impact Company, Crossroads Solar, Invests in an Automated Assembly Line for Solar Panel Production

Crossroads Solar

Case Study

Key Stats

Company History

Co-founders established Crossroads Solar from different backgrounds but a mutual passion for social and environmental impact.

Co-founders Patrick Regan and Marty Whalen brought diverse histories to the shared commitment that became the foundation for three-year-old Crossroads Solar. Patrick, now president of the company, came from the world of academia, starting his teaching career at Canterbury University in New Zealand and ending it as a professor of political science and peace at the University of Notre Dame. His academic research helped him appreciate the potential of solar energy to solve pressing environmental challenges.

With a degree from the University of Notre Dame and an MBA from Olivet Nazarene University, Marty became the third generation leader of his family’s office technology business. He continued in that position for five more years after the business was sold in 2012. Shortly before his retirement in 2017, Marty also began teaching prisoners at the Moreau College Initiative within Westville Correctional Facility. His wife, Kathleen, also worked in the program, teaching yoga and meditation. They both came to realize that despite an individual serving out their sentence assessed by the legal system, they were often held back in society because of obstacles they faced after release.

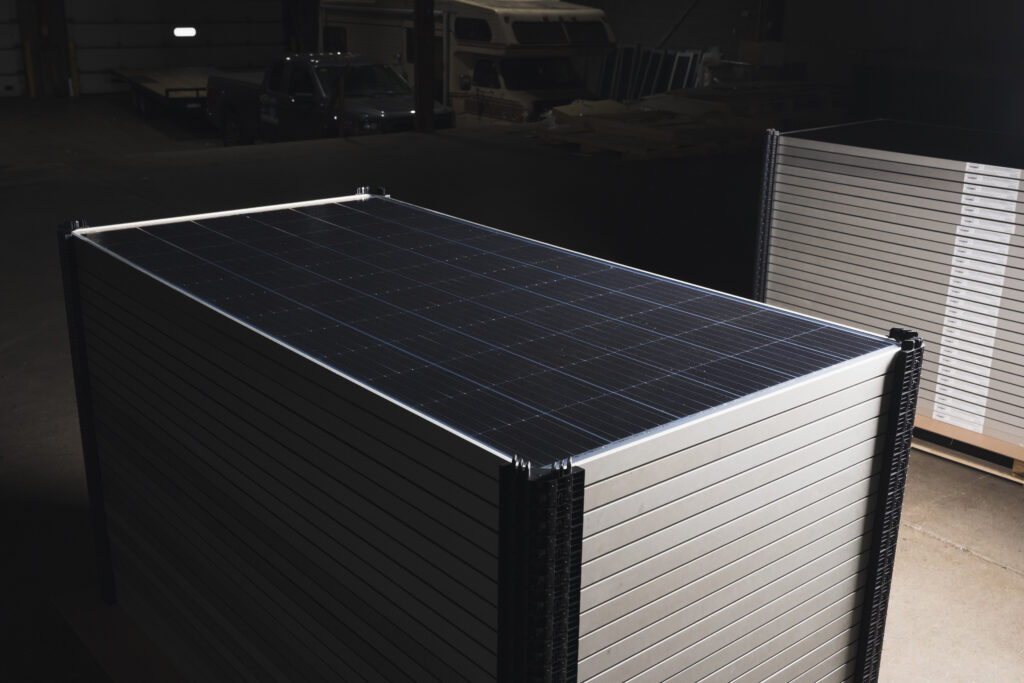

When Marty, now vice president of Crossroads Solar, partnered with Patrick, the owners created an experiment in South Bend: A company with core values of People, Planet and More Than Profit. They both agreed Crossroads would be dedicated to the concept that People matter most, providing formerly incarcerated individuals with the necessary income and life skills to earn a living wage with benefits and work that provide the dignity of skilled labor. The company’s second core value focuses on the Planet, producing quality solar panels for the alternative energy industry that supports efforts to safeguard the Planet’s transition away from carbon to a more sustainable future. In less than three years after its founding, Crossroads Solar has grown its workforce to 15 returning citizens and launched a successful product line consisting of monocrystalline solar panels backed by a 25-year performance warranty.

The Project

Crossroads Solar’s investment of $1 million in an automated solar panel assembly line will reduce manual labor, more than double its workforce and increase output 4-fold.

“We’re small in terms of production quantity compared to competitors,” Patrick said, explaining one reason behind the company’s new automation project. “But we make a great solar panel. By function and performance, our panels are close to the same as larger operations. At the end of the day, our product turns photons of energy from the sun into moving electrons that can power your house, your RV, your business or farm. In that sense, we’re the same. But we’re nimbler than our large competitors. We can respond quicker to individual requests from our clients. For example, we have lead times of a month or two months, where very large producers need a year or more lead time.”

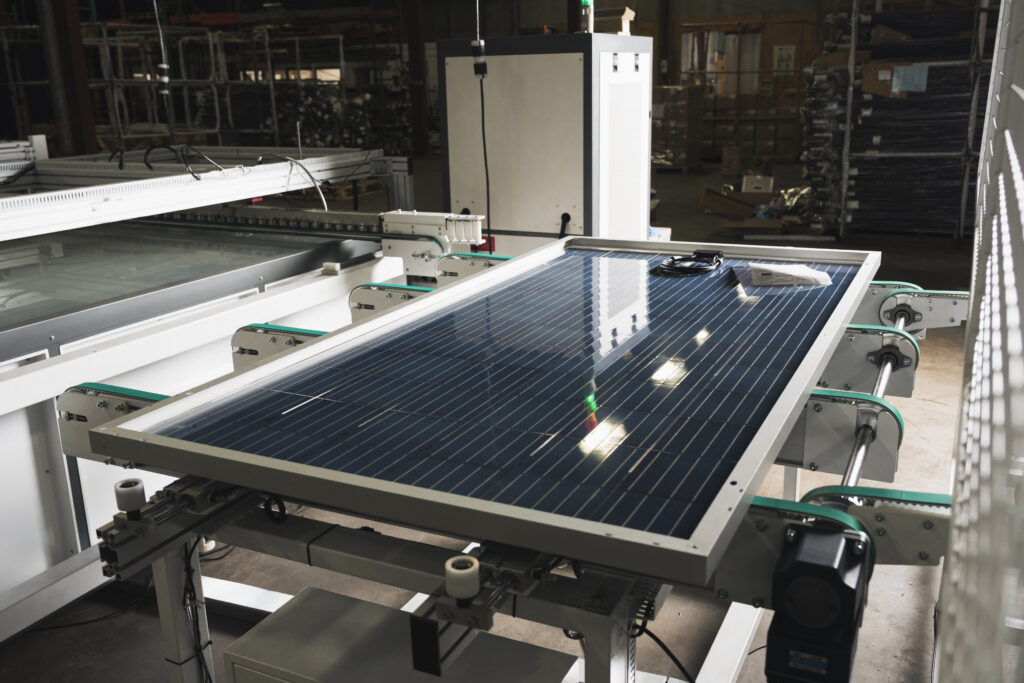

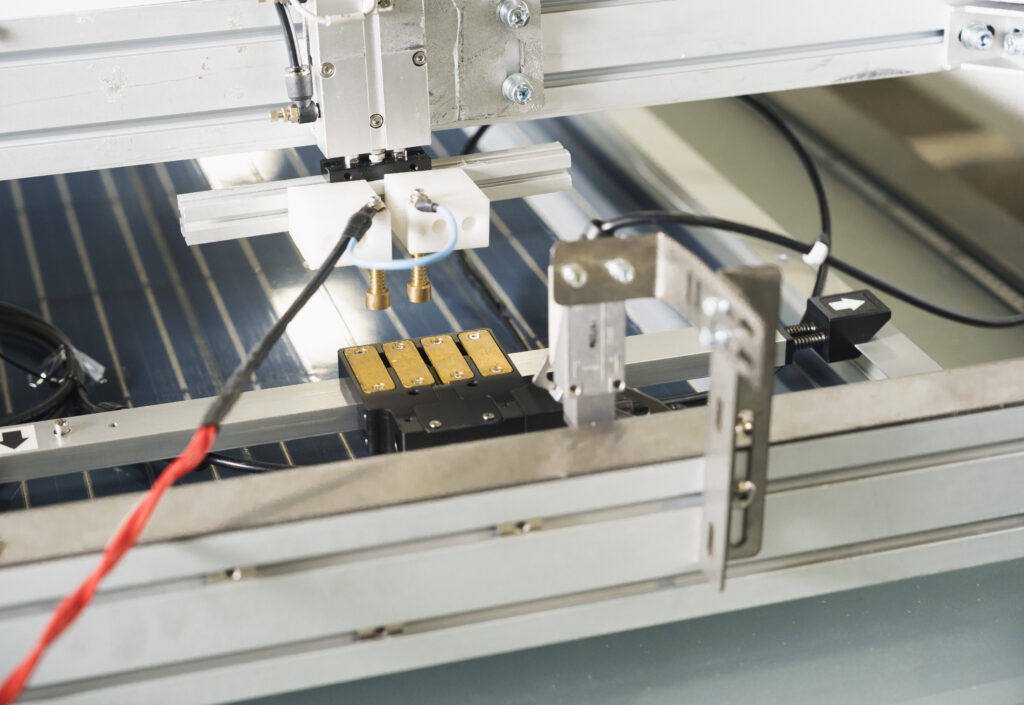

Crossroads Solar’s automated assembly line will enable even quicker customer service, while dramatically increasing its potential market share. While it will still make the same panel, the technology adoption project enables Crossroads Solar to manufacture products more efficiently. Where the manual assembly line involved workers carrying panels and parts from station to station for various production tasks, the automated equipment will significantly reduce these repetitive and strenuous tasks.

With the project goals understood, the Crossroads Solar leadership team began scoping out the automated assembly line in-house. Patrick illustrated the complexity of getting the new assembly line up and running. “We worked closely with the original equipment manufacturer (OEM) that makes the automated equipment. We explained what we wanted, the level of automation we wanted, the space we had available to house it and what we could afford. Between our plant manager, me and an engineer from the OEM, we worked it out. A team of engineers from the OEM helped us set the system up and trained our workforce on the new equipment. It was a major initiative,” he continued. “It was audacious.”

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity and productivity. Crossroads Solar made a giant leap toward expanding its market share in the solar panel industry with help from an MRG of $175,000.

Key Learnings

With a strong culture of upskilling, the Crossroads Solar workforce was prepared for the introduction of new technology in a production setting.

The Crossroads Solar workforce has demonstrated its willingness to learn new skills, and little — if any — reluctance to embrace new technology. “Most of our employees are now trained and operating the new equipment,” Patrick explained. “Those employees are now training other members on our team. The plan is to provide all our employees with the skills to build the panels and to fix the equipment that helps build the panels.” The workforce development plan also includes financial rewards for employee success, with a 12% profit-sharing incentive.

Acceptance of new technology in the workforce has enabled leadership to expand growth plans for the company. Patrick and Marty discussed what type of organization would be most conducive to success in a plant environment hiring only released felons as its workforce. “We considered taking the non-profit route and generating philanthropic support as a 501(c)3 organization,” Patrick said. “But we wanted to demonstrate that you can take a group of hardworking people, those who may be overlooked due to their past, and show that we can be a successful, profitable business while lowering recidivism rates. To do that, we need to make a great solar panel and compete in the marketplace.”

Having a big vision, building a talented workforce and leveraging resources like the Manufacturing Readiness Grants program are all part of a successful entrepreneurial journey.

The vision for Crossroads Solar came in different ways for Patrick and Marty. For Patrick, it began during his career as an academic and led first to his authorship of a book focusing on the politics of climate change. For Marty, it was steeped in his years as CEO of Martin Whalen Office Solutions and grew from his experience teaching and working in the prison system. “You could say we ‘willed the company into existence through our shared passion,’” Patrick explained. “We were resilient through COVID; we were resilient through the supply chain challenges after COVID; we just pushed through.” Like many entrepreneurs, it involved bank loans and financing to get things up and running. Patrick continued, “the Manufacturing Readiness Grants program provided less than 20% of what was a major investment for us, but it was a very important 20%. We are already in discussion for another similar assembly line expansion.”

“We wanted to demonstrate that you can take a group of hardworking people … and show that we can be a successful, profitable business while lowering recidivism rates.”

Patrick Regan

President at Crossroads Solar