EckCo Plastics Deploys Advanced Robotics to Streamline Production, Increase Efficiency and Improve Quality

EckCo Plastics

Case Study

Key Stats

Company History

In less than 25 years, EckCo Plastics has grown 5-fold, expanding the company’s product line and customer base, modernizing manufacturing processes and adopting technology.

In 2005 Gary Eck purchased a small privately held plastics company in Mishawaka, Ind. Today the company, now named EckCo Plastics, hasn’t just survived in the cyclical recreational vehicle industry, but grown 5-fold as it approaches its 20th anniversary. As president and owner, one of Gary’s initial changes at the company was to assemble a management team with more than a century of combined experience in the plastics industry. “We know what it takes to provide an excellent product at six-sigma levels for the lowest possible price,” Gary said. “Much of our current growth is because of enthusiastic referrals from our customers.” EckCo also builds its reputation by maintaining a large in-stock plastics inventory to respond quickly to customer deadlines.

Innovation is another reason for customer acquisition and retention. “Probably 70% of our sales are products that we own either the tooling or the patents for, or both,” Gary explained. He pointed to the RV window frames that are standard in RV manufacturing. While OEM manufacturers were ordering the same window frames that had been used since the 1970s—one assembled with screws—EckCo’s engineers decided that it was only time until someone was able to “invent a better mousetrap.” They decided to be that somebody. “We developed a snap-together frame that looks excellent and removed the screws,” Gary said, pointing to the biggest problem with the existing frames. “Just to make something snap together is easy,” he admitted, “but for repairs, you have to break the frame to replace broken glass. We managed to solve that issue and pass all the industry standards.” Today the EckCo-developed frame is used throughout the industry, and has largely replaced the older, hardware-heavy frame, “And that’s why our newly implemented robotic cell runs all the time.”

EckCo has used that philosophy to increase its product line, too, branching out to enter the market for other RV parts and equipment, such as wall components, windows and motor housings for awnings (an overhang).

The Project

The automated cell increases efficiency and lowers costs by reducing time-consuming and strenuous manual labor in the door frame production line.

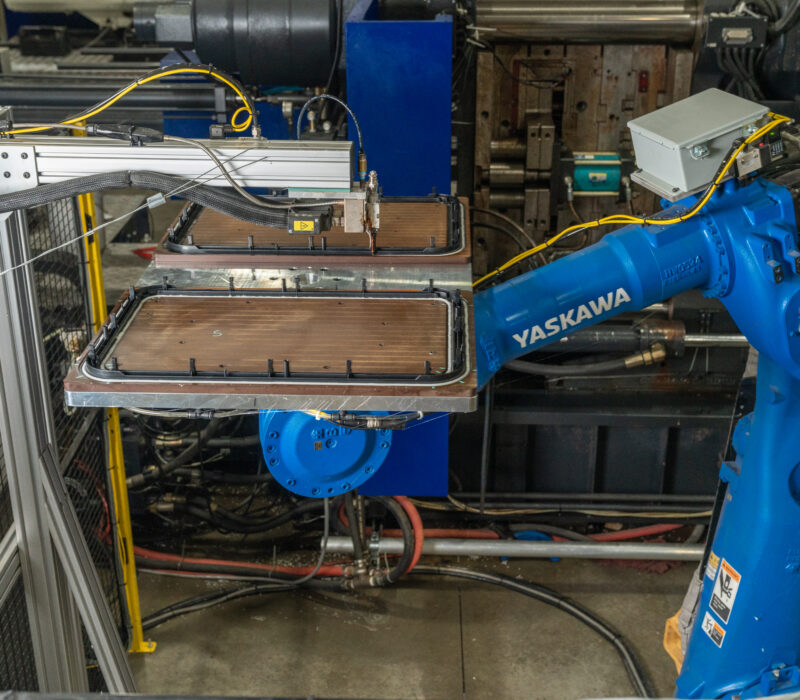

The Manufacturing Readiness Grants program was instrumental in EckCo’s expansion of its automation capabilities. “I guess the idea for automating our frame manufacturing process started probably three years ago,” Gary recalled. “In the process, we apply a gasket to the frame to eliminate the need for customers to apply a sealant when installing the door or window frame. It’s an in-demand product line that’s been at capacity for years. It’s not going to go away.” The gasket (insulation/seal) is a widely accepted advantage to RV manufacturers, he said, and customers pay a small premium for it because it saves them time and money in the long run. Manufacturing the frame with the gasket, though, is a complicated process that once involved two robots, along with manual loading, unloading, reloading of parts throughout the process.

Gary explained that an EckCo operator also was responsible for keeping the system operating at a continuous pace because much of the process depends on maintaining strict temperature controls. As a frame moves through the system, beginning with plastic ejection molding through to the installation of two gaskets on each frame, there are tight tolerances and time constraints to adhere to. “With the implementation of advanced robotics for loading, unloading and reloading, EckCo eliminates repetitive manual labor and inefficiencies occurring in the process. Now the operator can leave the process unattended to complete maintenance issues or other tasks,” Gary said. “Our process is now both more efficient and streamlined.”

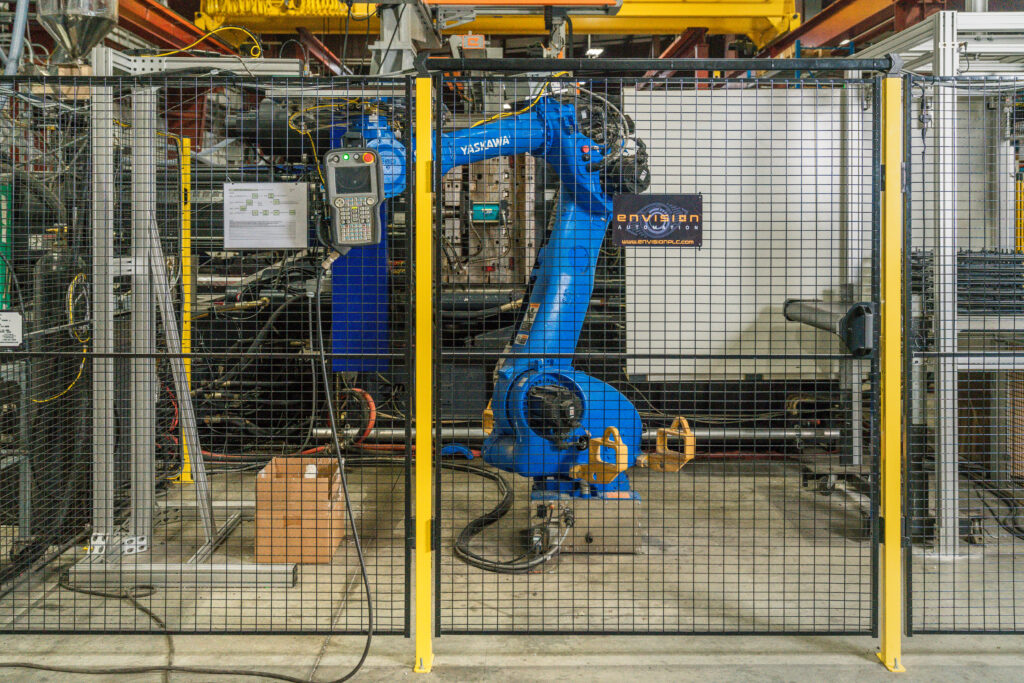

Envision Automation & Controls, an Indiana technology integrator that consulted with EckCo on technology implementation, was a valuable partner in the project. Their consultation included workforce training and systems integration. One of EckCo’s maintenance employees was pulled into the project for a few hours each day to participate in setting up and learning the automated system. Gary added, “Then our EckCo employee went on to train our lead operator on every shift. It has a ripple effect throughout the plant. Automation helps us pay more, upskill our workforce and provide a more pleasant work environment.”

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity. EckCo Plastics invested its $56,506 Manufacturing Readiness Grant adding a smart robotic system to streamline production, increase efficiency and improve quality.

Key Learnings

The Manufacturing Readiness Grant was a big incentive for EckCo to undertake this technology adoption project.

“I question if we would even have done the project without the grant,” Gary acknowledged. “I wanted to do it. We talked about trying to do it ourselves without a technology integrator. But the grant allowed us to get an integrator and say, ‘give us a turnkey solution.’ The culture at EckCo was acclimated to a robotic environment, and that made implementing the project much easier. “We still have some training to do, because right now our robotics knowledge is held by just a few people. We need the knowledge across shifts,” Gary said.

Some of Gary’s advice to other manufacturers is to “have procedures and knowledge-sharing in place. When you automate a process, you need to understand what can go wrong.” He suggests a quality improvement program combined with root cause analysis. “Eliminate some of the unintended consequences before you bring it 100% online for a full production run.” Even with our robotic cell up and running, we still have habits of wanting to do certain things a certain way.”

The new smart technology wasn’t intended to replace employees, it was deployed to augment the labor force.

“What we’re trying to do is to create jobs that are higher paying,” Gary explained. And that, he said, creates happier and more invested employees. “I can pay my employees more and keep us competitive with China and other international manufacturers.” One advantage EckCo carried into the project was a workforce that was deeply experienced working alongside robots. “We have a 3-axis robot on every injection machine in the shop,” Gary said. “Our employees are already used to the idea of identifying opportunities for more robotics and automation. Our culture is ‘if you can automate it and make our day-to-day better, just do it.’”

“Everyone is thrilled,” Gary reported. “I haven’t talked to one person yet who doesn’t like it. Our workforce loves it. When you have production targets to reach twenty-four hours a day, five days a week, it is a challenge. The new technology helps us reach those goals.”

“Have procedures and knowledge-sharing in place [for technology adoption]. When you automate a process, you need to understand what can go wrong.”

Gary Eck

President and Owner at EckCo Plastics