Hightech Signs Pivots to PPE Production During Global Pandemic with Help of a Manufacturing Readiness Grant

Hightech Signs

Case Study

Key Stats

Company History

Owned and operated as a family enterprise, Hightech Signs now boasts locations across state lines and customers throughout North America.

Doug Abramowski’s father founded Hightech Signs in 1988 as a regional sign company. Today, Doug has been its president for more than 14 years. Doug and his wife are sole owners of the firm, but benefit from advice when requested from Doug’s now-retired father. The business has locations in Terre Haute, Fort Wayne, Indianapolis and Grand Rapids and serves international customers with large-format digital graphics and signs. As a differentiating factor, the firm also places a strong focus on logistical solutions.

“We’re known as a large format digital printer,” Doug explained. “We print really large things—banners, fabric backdrops, tradeshow graphics and event signage, and we do a fair amount of work in the short-term retail space. We barcode for them, and customers actually order through their online network and send us all the orders each day. We integrate those with FedEx, and return the list to them with tracking numbers for each sign that we send out.”

Business was flourishing until the COVID-19 pandemic hit. When trade shows and retail sales slowed down, the demand for the kinds of signs Hightech produces nearly vanished. “We had been running all-out for months and then everything stopped,” Doug recalls. “My people were exhausted. They had been working 60-hour weeks with overtime paychecks. And then March, 2020, it all stopped on a dime.”

The COVID-19 Response Project

Despite a shutdown of operations during the early days of the pandemic, Hightech Signs would soon roar back into production by supporting Indiana’s COVID-19 response.

When the COVID-19 pandemic hit, everyone came quickly to the realization that personal protective equipment (PPE) was scarcely produced in the United States. The U.S. government began to lean on local manufacturers to convert manufacturing facilities and equipment for ventilators to surgical masks. Facing the unknowns of the pandemic and the reality that business was slowing, Hightech decided to shut down the plant for two weeks. “However, we had the equipment, the supplies and expertise to make, print, cut and assemble face masks,” Doug said. “And literally in those two weeks, I’m hustling to see about the potential.”

In March, Indiana officials were trying to procure N95 masks and talking to potential vendors. Doug started bringing back a small group of his employees to start running prototypes. “We quickly ran through two or three iterations that we couldn’t breathe in,” Doug recalled. “We were fully socially distanced, everything. But we wanted to do something to entice employees to come back to work. You’re going to be doing something good for the community. Not only are you going to be making masks that will make money, but we’re also giving back a significant portion to charitable groups here in Fort Wayne.”

Ultimately the business case in pivoting to mask production came down to the speed at which Hightech Signs could cut the mask material. Doug was looking at the Manufacturing Readiness Grants (MRG), thinking, “Do I take the time to apply for a Manufacturing Readiness Grant, I think we can do it.”

Hightech Signs invests in an automated fabric cutting machine, successfully pivoting to high-volume mask production during the global pandemic.

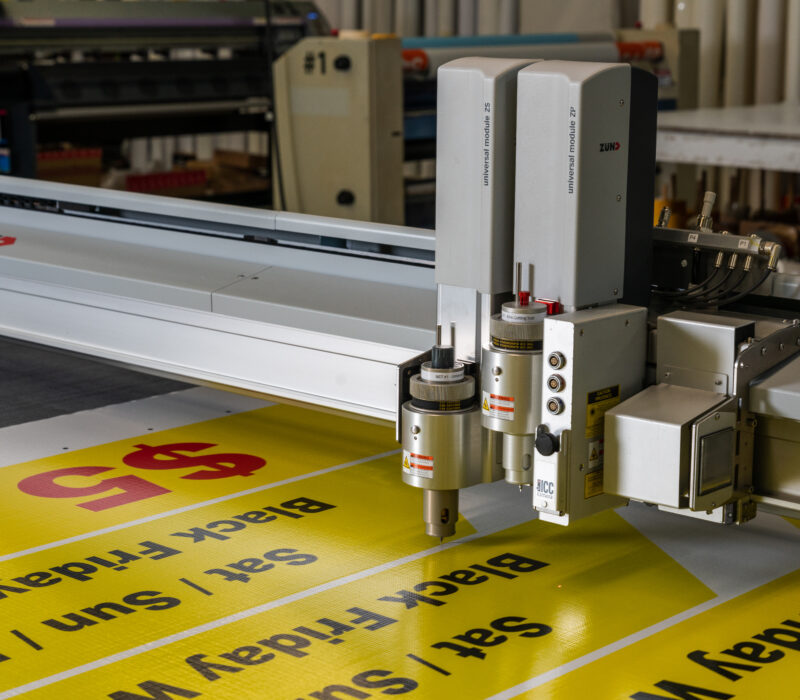

“The cutting machine is by far the most sophisticated piece of equipment we have in our shop,” Doug said. “It has a camera over the top of the 10-foot by 10-foot table that can read all the crop marks and all the spots for cutting what’s on the table. And then it snaps a picture, which is a lot quicker than manually moving around the table to map all of the necessary marks. And then the machine cuts very accurately to them.” With the new automated fabric cutter, Hightech Signs was also able to expand from “basic” mask production (cloth) to masks using EHS (Environmental Health and Safety) medical-grade materials.

Although the manufacturing pivot was a challenge initially, it was also a huge success. Hightech Signs gave away more than 10,000 masks to local Fort Wayne charities in a 1:1 ratio; for each mask purchased by a consumer–masks were also distributed by the organization into local churches. Hightech Signs would go on to sell more than 50,000 masks after the project was completed and the automated cutter was installed. Looking out into 2022 and 2023, the automatic cutter will also improve the quality and mix of Hightech’s offerings when business returns to normal post-pandemic.

Manufacturing Readiness Grants provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity, as well as companies willing to invest in healthcare manufacturing to support critical COVID-19 response. When the COVID-19 pandemic created an urgent need for personal protective equipment (PPE), Hightech Signs invested in new smart technology and ramped up capacity for face mask production.

Key Learnings

Lean on Indiana’s robust network of manufacturing companies for support.

The biggest learning Doug wanted to share with others was the importance of being connected in your space. Knowing other manufacturers and learning from them resulted in Doug learning about the MRG, and at exactly the right time. “I had a business plan in January 2020, and that got trampled by the pandemic. But the good news of the pandemic is how many good stories—from training our staff to increasing our level of technology, making a difference in the pandemic and having a commercially viable PPE strategy.” Doug said Hightech Signs is now “over-using the automated cutting machine. It is the most sophisticated piece of equipment in the shop.”

A tight-knit company culture can accelerate the success of a technology adoption project.

Hightech Signs had a strong company culture prior to the pandemic. Employees understood and appreciated that the company doesn’t “let people go,” and that the decisions being made [investing in new technology and equipment] were intended to grow the business and protect jobs. The equipment manufacturer came in to help implement and train employees on the machine. Doug mentioned that the employees immediately found it “cool to run,” and that it had a serious “wow” factor compared to some of Hightech Signs’ existing equipment.

“The team knew we’ve been chasing lean manufacturing and implementation for a decade” Doug said. “They know who we are and where we’ve been, and they saw that nobody got laid off during COVID-19. We were making good on our commitment to a strong company culture. They know my heart and where we are as a family business. They know we’re not looking to cut people just because we’ve created some efficiency with the new tech. We’re looking to grow our existing business, enter new markets and grow our workforce. We’ve got big ambitions and the right employees to meet them.”

“We’re looking to grow our existing business, enter new markets and grow our workforce. We’ve got big ambitions and the right employees to meet them.”

Doug Abramowski

President at Hightech Signs