Mach Medical Develops a Digital Twin for High Velocity Single-Piece Flow Manufacturing

Mach Medical, LLC

Case Study

Key Stats

Company History

Mach Medical’s approach to OEM orthopedic implant manufacturing is designed to revolutionize the orthopedic supply chain.

As Co-Founder and General Manager of Mach Medical, Steve Rozow understands what it takes to succeed in a technology company that is disrupting an industry. In a rapidly growing enterprise, he said, “everyone’s job duties are fluid. I step in wherever my help is needed to get the job done—from getting the mail to helping with an array of complex engineering problems.”

Mach Medical is a contract manufacturer that builds orthopedic implants for original equipment manufacturing (OEM) companies. Since 2019, the company will have invested $14 million to rapidly scale up operations with the goal of creating hundreds of new jobs by the end of 2025. Part of that investment was the creation of a new facility in Whitley County’s US 30 corridor between Warsaw and Fort Wayne in Columbia City, Indiana, also known as “Orthopedic Alley.”

“Mach Medical was created with the goal of revolutionizing the orthopedic supply chain by developing and deploying disruptive supply chain platforms,” Steve explained. “We want to build product that economically meets clinical demands through a partnership with sister company, SITES Medical, while radically reducing implant inventory and time to market for our customers in fields like total joint replacement, spine technology, trauma and other medical implants. Our job is to build the highest quality implants in response to an individual patient’s pre-operative surgical plan and supply that product in time for the patient’s surgery.”

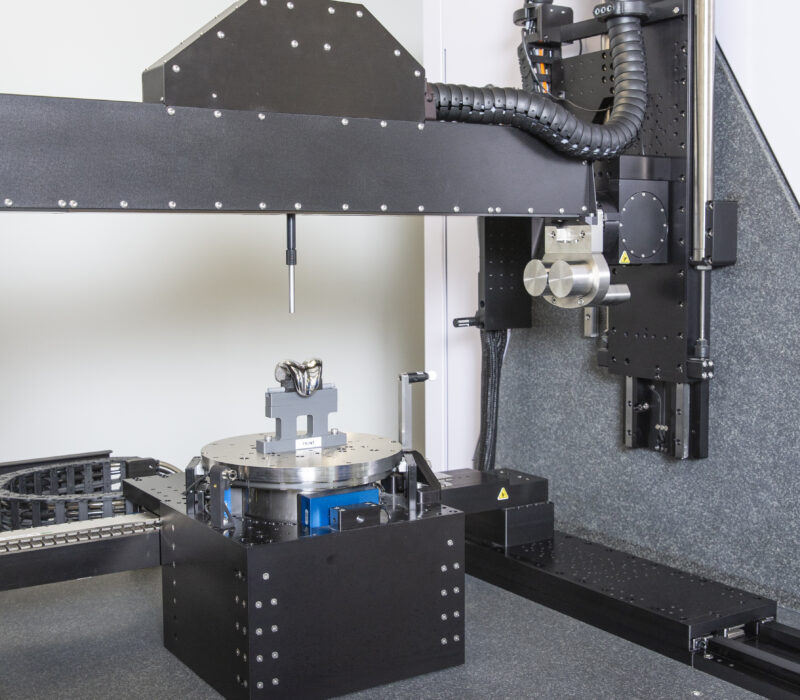

To accomplish that feat, Mach Medical employs a proprietary high velocity, single-piece flow manufacturing process that can build a single implant as efficiently as a batch or continuous manufacturing processing. “By delivering only the implants needed for a single procedure, we can unleash customer value that goes beyond per-piece cost efficiency,” Steve said. “Notably, inventory requirements for our OEM customers can be reduced by as much as 80%.”

The company’s end-to-end supply chain management is another essential piece of the company’s competitive edge, which includes everything from automated and compressed translation of the engineering specs to executable manufacturing, as well as raw material acquisition through sterilization, surgery procedure kitting and inventory management. Our ‘Virtual Factory’ will provide real-time access to performance metrics and other critical aspects of the customers’ orders. “We call it ‘Industry 4.0 Realized,’” Steve said.

The Project

Mach Medical develops a digital twin solution for high velocity single-piece flow manufacturing.

Steve describes a key challenge in the orthopedic implant market as the length of time it takes to translate new product designs into a practical manufacturing process. “It’s similar to manufacturing a shoe design,” he said. “Each shoe is based on a single design that must be scaled to fit an entire population of different sizes, shapes and widths.” Manufacturing a specific medical implant family is similar in that the manufacturing process, tooling, inspections and other elements of manufacturing are essentially the same for each part in a family, but just need to be scaled across all the sizes in the product line. Each implant size traditionally requires significant engineering resources and time to complete even after the first size is completed. “The effort is very repetitious, and for certain products, the time it takes to execute that work can be measured in years.”

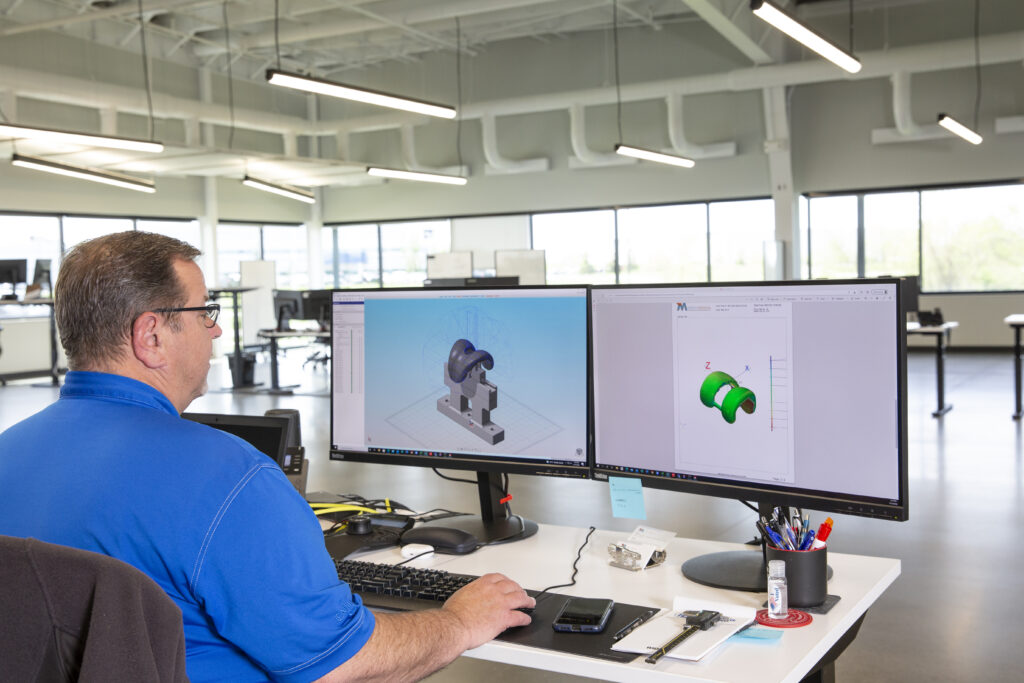

Mach Medical’s answer to this challenge is through developing a comprehensive “digital twin” of the manufacturing process tied to a standardized manufacturing platform, which significantly reduces the engineering time and resources it takes to translate the product design specifications to executable manufacturing. Additionally, key aspects of the manufacturing process can be tested, iterated, and evaluated in the virtual world before proceeding to manufacture it in the physical world. “As you might imagine,” Steve said, “there was a great deal of R&D and software development in this solution.”

“The digital twin solution is built on Mach’s comprehensive manufacturing process data. Then auto-populated product-specific data, that will drive our manufacturing operation,” Steve explained. Because of the complex nature of the project, Mach Medical is partnered with two other technology solution providers. “We are working with CGI, an integrator of Microsoft Dynamics, and Siemens to configure the platforms and build the interfaces that execute the auto-population of the systems to drive our manufacturing process. Success for Mach Medical will be determined by how much faster we are at delivering products than others within the industry —an improvement we conservatively estimate to be at least 20% faster.”

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity. Mach Medical earned grant funding to implement a proprietary “High Velocity Single-Piece Flow Manufacturing” process with digital twin technology.

Key Learnings

Never underestimate the level of complexity to develop and deploy an innovative technology solution.

“The more we dove into the project, the more complicated it became,” Steve recalled. “We may have underestimated the level of complexity of integrating the digital twin solution. Ultimately, though, it provides us the ability to rapidly translate design specification to executable manufacturing without compromising quality in this highly regulated healthcare environment. As we perfect the technology, it will be a huge competitive advantage for Mach Medical.”

Still, Steve cautions other innovators to give themselves adequate development time, room for iteration as well as funding to execute the truly ground-breaking ideas. He also put a fine point on expecting setbacks. “When you’re doing advanced and innovative projects,” he advised, “sometimes what comes out of it may not be what you initially planned, but it can still be extremely valuable in another way. As long as you document and learn from each setback, you’ll be in a better position to bring the idea to fruition.” Having a robust methodology is valuable because there are many ways to achieve a certain goal, and finding the critical path with limited resources is vital–especially in a rapidly growing enterprise.

Mach Medical’s culture of innovation and disruption requires a tech-savvy workforce.

The company is recruiting employees who are curious and eager to do things differently than they are done today, Steve stressed. “A core attribute at Mach Medical is striving to build a platform where people can do the best work of their careers.”

“We need people who want to solve problems,” Steve said. “We have assembled some of the strongest talent in the region to support this project.” He pointed to a workforce that includes two world-class engineers who have worked on high-tech projects for nearly 3 decades, and a team leader who has led three complex global supply chains in the medical device industry.

“A core attribute at Mach Medical is striving to build a platform where people can do the best work of their careers.”

Steve Rozow

General Manager at Mach Medical, LLC