TouchTronics Invests in New Equipment to Enhance Product Quality and Bring Product Testing In-house

TouchTronics Inc.

Case Study

Key Stats

Company History

TouchTronics designs, programs and produces wireless 12-volt and 24-volt access and lighting controls, environmental monitors, mechanical controls and a range of wireless applications.

The story of Elkhart’s TouchTronics echoes the classic entrepreneurial tech start-ups of the late 20th and early 21st centuries. Alice Poseley graduated with a degree in chemistry, “I thought I would like that,” she recalled. “But once I got a job actually doing chemistry, I hated it.” Deciding sales would be a better fit for her, she took a job as a sales rep in the RV industry and was the first woman sales rep in the industry. Alice said, “There were two other women in RV sales, but both worked for a company and sold RVs. As a sales rep, I sold everything from hub caps and windows to wood and other things like that.” And as Alice learned more about the industry, she realized her future would be in manufacturing products, rather than just selling them.

Although Alice had no manufacturing experience or any real idea of what it entailed, she learned more about the companies she represented and studied one that made switch panels. “I thought, ‘how hard can that be? You get a piece of metal, you paint it and put switches in it.’ Boom, you’re done. You don’t even have to put harnesses on it.” Her research showed manufacturing a panel that sold for $30 to $40 cost only about $8 to make. In 1984, Alice recruited her sister and best friend to join her as partners in TouchTronics. Ron Mathia was added as a partner and teacher to cover the electrical engineering needs of the company. Before officially joining TouchTronics, Ron worked with Alice for many years to design new products and analyze quality issues. Alice said, “It was like going to college every week to study electronics.”

Putting her sales experience to work, Alice brought a couple of initial customers to the recently launched company that was ready to purchase the first TouchTronics products. By 1990, the company’s revenue was about $300,000 annually, and TouchTronics began expanding into the automotive and trucking industries. Today the company designs, programs and produces wireless 12-volt and 24-volt access and lighting controls, environmental monitors, mechanical controls and a range of applications in wireless RF, RFID, Bluetooth and CAN Bus (Controller Area Network) applications, with annual revenues in the millions. TouchTronics’ Elkhart, Indiana, facility boasts some 60 employees and recently added two big names to its customer roster.

The Project

Bringing product testing and validation in-house would save money in the long-run and significantly improve product quality for customers.

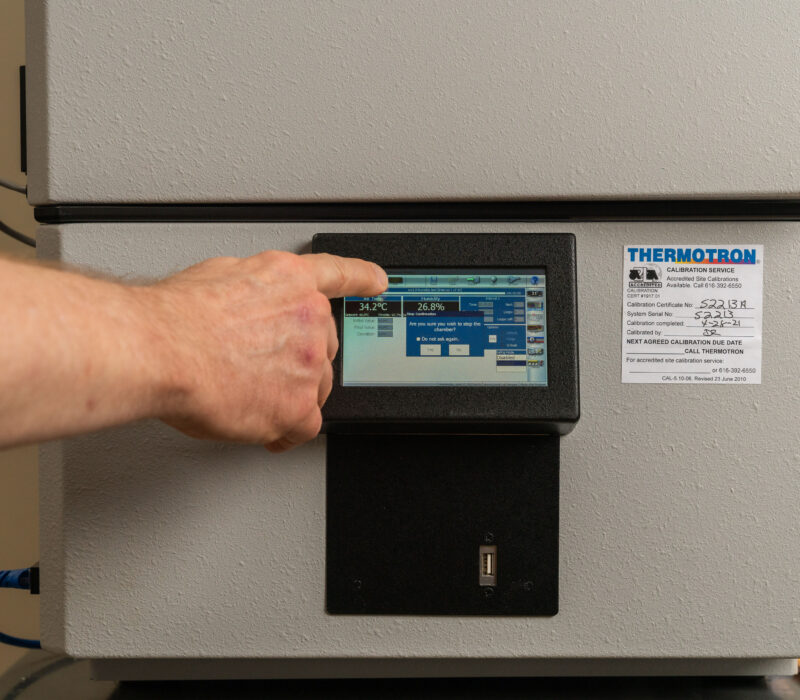

In mid-2020, TouchTronics was looking at the next step in its technology adoption roadmap. Purchasing an environmental chamber, a new spectrum analyzer and a low-pressure molding machine was high on Alice’s wish list. “These are the pieces of equipment I wanted to have,” Alice said. Prior to the implementation of the equipment, in-house testing was not possible. Instead, TouchTronics ultimately relied on customers to advise if a product failed in the field. Failure required the company to redesign, rebuild and resubmit the component. “Now all the new products we’re making are tested with that equipment,” she explained. “All our new designs and printed circuit boards go in the environmental chamber at all required temperatures. Now we can verify and validate that our chance of retaining quality and functionality in the field is very high before a product ever leaves our plant. The new equipment helps maintain the quality we believe we owe our customers.”

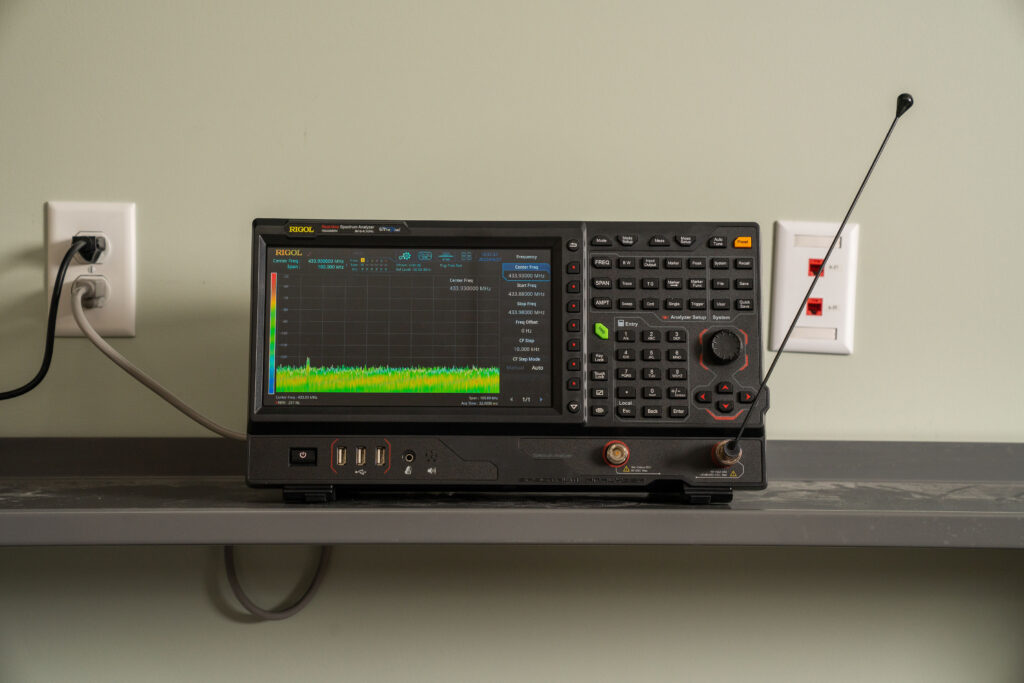

The other piece of the project offers additional safeguards in product quality, too. The spectrum analyzer is primarily used in the design phase of the product lifecycle. Alice said, “This was a solution that enabled our engineering department to become more effective across the board. The spectrum analyzer identifies any issues so we can fix them before they become problems in the manufacturing phase.” As an example, she said, “sometimes when you’re writing software, you have things that don’t work as expected on your printed circuit board. The analyzer is yet another tool our engineers can use to diagnose those issues. Now it has become another part of our engineering and pre-testing process. And we can present that extra capability to our current and potential customers to secure new business.”

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity. TouchTronics’ invested in new equipment to enhance product quality and bring product testing in-house with the help of grant funding.

Key Learnings

Show customers that you are investing in your manufacturing processes to keep them in the long run.

While it’s very hard to acquire a new customer, it’s 10 times harder to keep a customer,” Alice said. And she went on to share her belief in the best way to retain customers: “If you aren’t showing that you’re growing your engineering and manufacturing capabilities, you won’t keep your customers,” she said. “They should have confidence that they’re going to continue getting quality product from you. We have a very nice facility and we spent quite a bit of money remodeling our buildings. We want our shop floor to look as technical and professional as we are. So, every year we budget what equipment and capabilities we need to upgrade. If a customer is going to continue to invest in doing business with you, they want to see that you’re investing in yourself with a pace of progress.”

Consistently invest in new equipment and technology to remain competitive.

Still, Alice said, buying the best equipment and technology is important, too. “While we are a very fiscally conservative company, we do believe in spending money on the newest and greatest equipment,” she shared. “Always buy the best equipment that you can afford to buy. And, if you can afford it, buy new because you get the warranty and all the training that goes with it.” In fact, she added, “Sometimes you have to think, ‘Can we afford it? And if we don’t prioritize it, will we still be in business?’ That’s our philosophy. If you need a piece of equipment, figure out a way to get it because it’s going to make you more productive, and your employees will be happier.” Along with the strategy of keeping up with new technology, Alice has also focused on purchasing from local vendors and solutions providers and maintained TouchTronics inventory levels to stay relevant as a supplier to large companies. Finally, the organization has tried to consistently redesign its products to allow for flexibility in materials and processes and to improve quality.

“If you aren’t showing that you’re growing your engineering and manufacturing capabilities, you won’t keep your customers.”

Alice Poseley

President at TouchTronics Inc.