Circle Bev Invests in Automated Equipment to Triple Its Manufacturing Capacity with Help of a Manufacturing Readiness Grant

Circle Bev

Case Study

Key Stats

Company History

Since introducing its Kombucha drink in 2015, Circle Bev’s rapid growth has expanded to co-manufacture drinks for as many as 20 partner brands across the country.

Matt Whiteside’s journey into entrepreneurship took him around the globe to co-founder and CEO of Circle City Sonorans LLC by way of Arizona State University, where he earned a degree in supply chain and accounting. He put that degree to work at Rolls-Royce in a job that took him from San Francisco to England, Germany and Ohio before landing back in Indianapolis. “After moving cities several times, I got to the point where I decided it was time to pursue a path that better served my goals of community building and helping people. I wanted to stick to manufacturing and put my technical abilities to work but do it in a slightly different way.”

It started with Kombucha—a fizzy and fermented tea drink, low in sugar and offering probiotics—that Circle KOMBUCHA (the brand name of the company’s proprietary drinks) sold directly to consumers at Central Indiana area Farmers markets in 2015. It didn’t take long before Matt and co-founder Skylar Williams moved from their first 2,000-square-foot facility in Irvington (an eastside Indianapolis community) to 18,000 square feet in the former Angie’s List building in the Elevator Hill development on East Washington Street. Now, less than a decade since it became Circle Bev, the company fills 80% of that building, providing room to expand its contract manufacturing business and inaugurate its next growth stage.

The Project

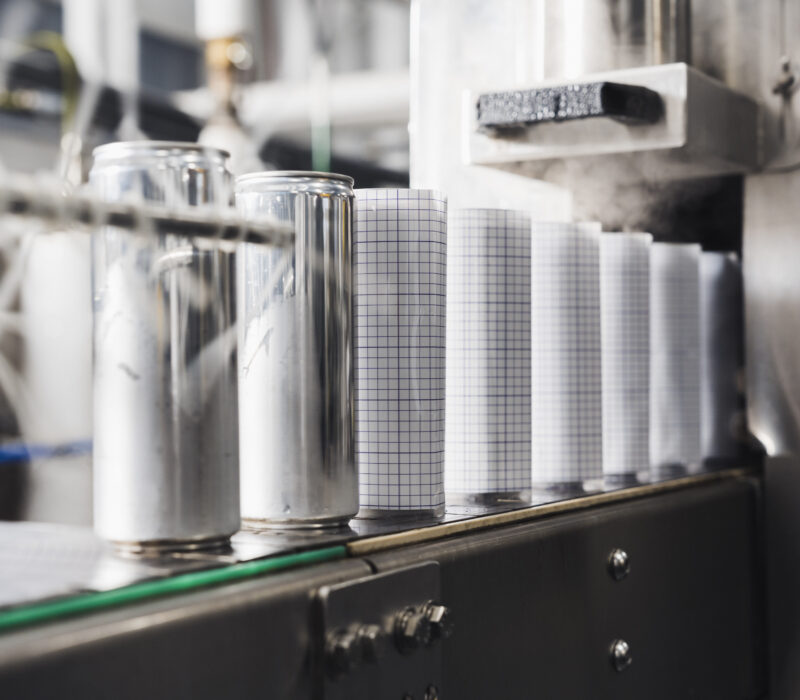

Circle Bev used its Manufacturing Readiness Grants award toward the purchase of a robotic sleever—automated production equipment that would triple its daily production capacity.

Matt explained that most aluminum beverage cans are identified by name, logo, the beverage and other legally required product information which are usually printed directly onto the can. “To manufacture beverages under this method, it must be done in very high quantities to make it cost-effective,” Matt said. “While many larger beverage companies print beverage information directly onto their cans, it can be prohibitive for innovation and new product launches. If a company wants to test a new product, they would need to purchase thousands of these printed cans.”

However, a relatively new technology called robotic sleeving allows smaller beverage manufacturers a more agile and cost-effective alternative. Sleeving adheres a printed label to the outside of the can in a process that is almost indistinguishable from can labels that have been printed directly onto the aluminum. “The sleeving process allows us to run more innovative products because companies can test the market with maybe 10,000 of this flavor or 5,000 of that other flavor. The robotic sleever we installed allowed us to go after new projects that we couldn’t have undertaken previously.” Matt continued, “Now somewhere between 70% to 80% of every product we produce is being sleeved with that equipment. You can imagine, 70% to 80% of our business wouldn’t exist today had this project not moved forward. And the Manufacturing Readiness Grants award helped us significantly accelerate the timeline of the technology project.”

With the new sleeving equipment, when the labels are delivered to the Circle Bev plant, each is placed on a can by the robot sleever. It then goes through a heat tunnel that adheres to the can. “It required us to upskill our workforce because this is not a manual task. The process gives us a great deal more flexibility to contract new projects and serve a much wider breadth of clients,” Matt said.

Manufacturing Readiness Grants provided by the Indiana Economic Development Corporation (IEDC) and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity and productivity. A Manufacturing Readiness Grants award helped Circle Bev invest in new automated equipment that would triple the company’s manufacturing capacity.

Key Learnings

Technology adoption projects can take longer and be more complicated than first anticipated.

“The expansion project is still ongoing,” Matt said. “We’ve made a lot of investments, a robotic sleever being one of them. But really our whole plant was upgraded. Implementing that first phase—the robot sleever—was a big challenge, but fun,” he said. “The project itself took at least twice as long as we expected. It was primarily because procuring the equipment was more time-consuming than we had ever imagined. Some of the project timeline can be blamed on the supply chain issues, but not all of it.” Next time, he said, the company will “plan for double as much time as we think we need and a bigger budget. Technology adoption takes planning, financial capital, and time to execute.”

If you are a manufacturing entrepreneur, lean into Indiana’s ecosystem of resources and support networks.

Matt mentioned his reliance on tapping other Indiana entrepreneurs to support his venture. “In the last few years, I’ve been calling on the folks who are running big plants, small plants, everything in between,” he said. “I haven’t yet stumbled on anything too structured like a formal network of manufacturing entrepreneurs, but thankfully we’re very much a ‘pay it forward’ community. Too often, we’re too busy getting the job done that we don’t always take time to get together, share best practices or simply just network with one another.”

Technology adoption leads to new job functions, higher wages and more challenging work day-to-day.

In 2020, when Circle Bev initially submitted its application for a grant, its Indiana workforce was 24. While the number hasn’t grown significantly since the project has been implemented, the impact has been felt in its full-time employment. “In 2020, only about 10 of the Circle Bev employees were full-time and the rest were part-timers,” Matt shared. “Now many of those part-time positions have transitioned to full-time employees, and that number is growing every week. We’re starting to see the need for about 20 to 25 full-time employees, and if we think about adding a second shift, we might get into the 40 to 50 range. The most important thing is that those who are working for us full-time have benefits and their average hourly wage is considerably higher than where we were 2 years ago.”

Before the technology adoption project, Matt said, many employees were physically moving products around. “We don’t have a lot of manual labor in our production process anymore–there’s really no manual touching of the can. Many of our shop floor employees have been upskilled to run the automated equipment,” Matt said. “Their day-to-day job is more about setting up the equipment and making sure we are meeting the quality requirements of our customers. Everyone is doing more challenging and demanding work.”

“Many of our shop floor employees have been upskilled to run the automated equipment… Everyone is doing more challenging and demanding work.”

Matt Whiteside

Co-Founder & CEO at Circle Bev