Case Studies

Tactile Engineering

Tactile Engineering staffers work at desks and electronics workstations, performing assembly and testing tasks. A robot arm moves a suction tube to position a tiny plastic dot in a tray with hundreds of holes. A rapidly spinning rod winds copper wire into a tight coil. Behind a green safety shield, a laser beam flashes over metal parts.

Accutech Mold & Machine

Accutech Mold & Machine Paired two Manufacturing Readiness Grants (MRGs) to support Autonomous Robotics, Sensor Technology Adoption and Digitizing Machine Operations

Jasper Group

Jasper Group Makes Bold Leap into Industry 4.0 with Adoption of Autonomous Mobile Robots in its Orleans, Indiana, Plant

Complexus Medical

Manufacturing Readiness Grant Spurs Growth for Complexus Medical and Opportunities for its Workforce

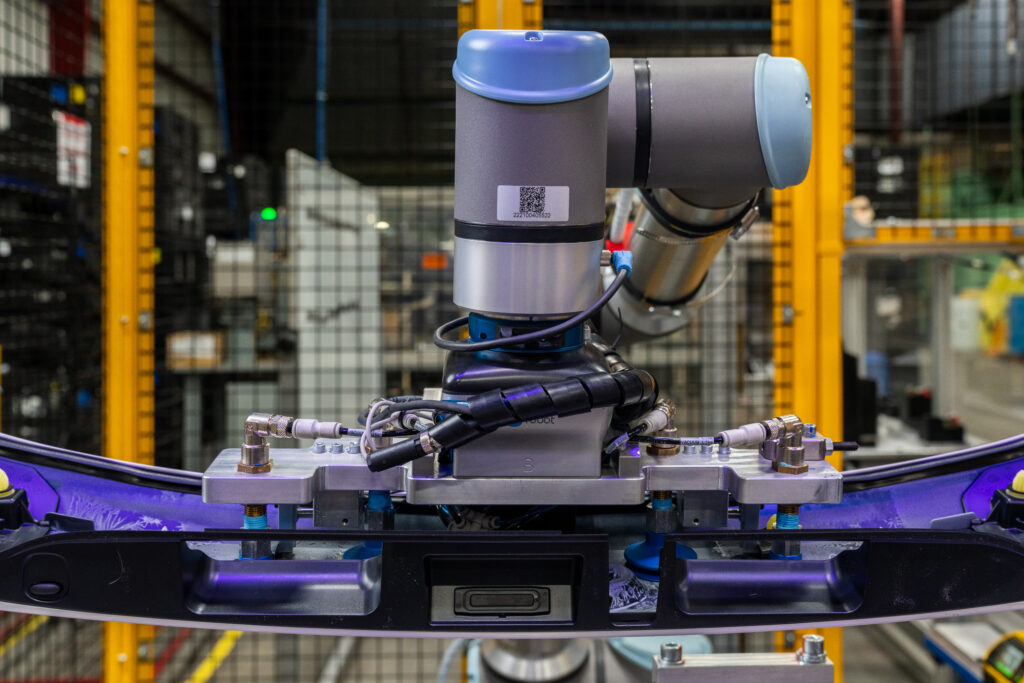

Batesville Tool & Die, Inc. (BTD)

Batesville Tool & Die Invested its Manufacturing Readiness Grant in Advanced Robotics with Integrated Machine Vision to Significantly Grow its Manufacturing Capacity

Chiyoda USA

A Fully Integrated Automation Line Becomes Reality at Chiyoda USA with Support from a Manufacturing Readiness Grant

Oscar Winski Company

Oscar Winski’s manufacturing story began with opening his first scrap metal business with his son, Louis, in Lafayette, Ind., in 1907. Today, that company retains its original entrepreneurial spirit, with […]

Soil-Max Inc.

Soil-Max Implements an Innovative Robotic Welding System to Create a Dynamic Manufacturing Process

Smoker Craft Inc.

Smoker Craft Installs Custom-created Robotic Tube Welding System Saying, ‘There’s Nothing Else Like This in the World.’

EckCo Plastics

EckCo Plastics Deploys Advanced Robotics to Streamline Production, Increase Efficiency and Improve Quality